Jade imitated PC material and preparation method thereof

A technology of imitation jade and luminous agent, applied in the field of imitation jade PC material and its preparation, can solve the problems of no fluorescence, bright and clear, etc., and achieve the effect of rich fineness, high application value, and long luminous duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

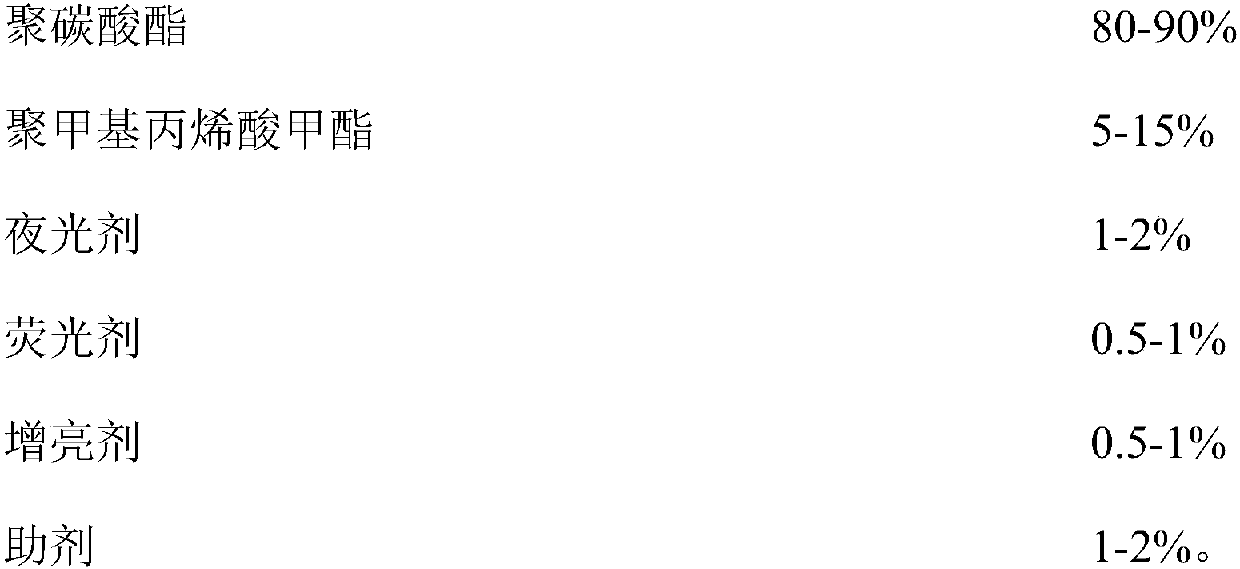

[0046] The jade-like PC material in this embodiment includes the following components by weight percentage:

[0047]

[0048] Prepare jade-like PC material through the following steps:

[0049] (1) Combine polycarbonate, polymethyl methacrylate, rare earth luminous agent, fluorescent green, brightener (brightening agent OB-1), hindered phenol anti-aging agent, ethylene bis-stearamide , Antioxidant 168 and Antioxidant 1010 are mixed in the mixer for 5 minutes;

[0050] (2) Add the mixture obtained in step (1) to a twin-screw extruder for melt blending. The temperature in the first zone is 220°C, the temperature in the second zone is 230°C, the temperature in the third zone is 240°C, and the temperature in the fourth zone is 250℃, temperature in zone five is 255℃, zone six is 255℃, zone seven is 265℃, zone eight is 255℃, zone nine is 255℃, screw speed is 300r / min, residence time is 1 minute . After extrusion, cooling, drying, and pelletizing, the jade-like PC material is obtained....

Embodiment 2

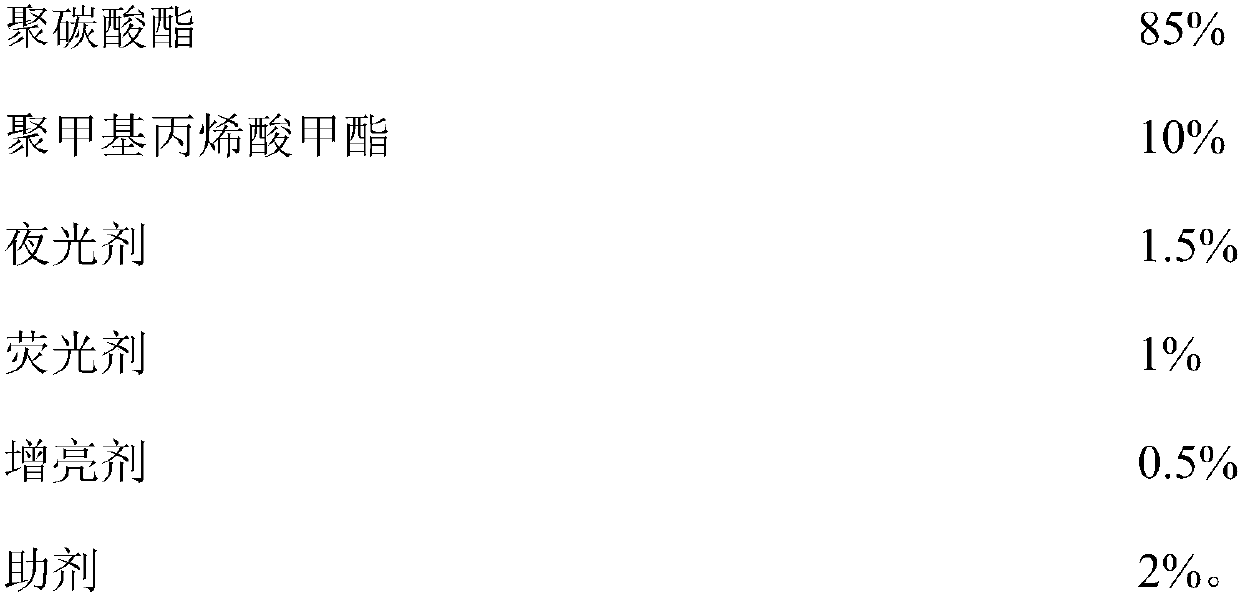

[0052] The jade-like PC material in this embodiment includes the following components by weight percentage:

[0053]

[0054]

[0055] Prepare jade-like PC material through the following steps:

[0056] (1) Combine polycarbonate, polymethyl methacrylate, rare earth luminous agent, fluorescent green, brightener (brightening agent OB-1), hindered phenol anti-aging agent, ethylene bis-stearamide , Antioxidant 168 and Antioxidant 1010 are mixed in the mixer for 5 minutes;

[0057] (2) Add the mixture obtained in step (1) to a twin-screw extruder for melt blending. The temperature in the first zone is 220°C, the temperature in the second zone is 230°C, the temperature in the third zone is 240°C, and the temperature in the fourth zone is 250℃, temperature in zone five is 255℃, zone six is 255℃, zone seven is 265℃, zone eight is 255℃, zone nine is 255℃, screw speed is 250r / min, residence time is 2 minutes . After extrusion, cooling, drying, and pelletizing, the jade-like PC material is...

Embodiment 3

[0059] The jade-like PC material in this embodiment includes the following components by weight percentage:

[0060]

[0061] Prepare jade-like PC material through the following steps:

[0062] (1) Combine polycarbonate, polymethyl methacrylate, rare earth luminous agent, fluorescent green, brightener (brightening agent OB-1), hindered phenol anti-aging agent, ethylene bis-stearamide , Antioxidant 168 and Antioxidant 1010 are mixed in the mixer for 10 minutes;

[0063] (2) Add the mixture obtained in step (1) to a twin-screw extruder for melt blending. The temperature in the first zone is 220°C, the temperature in the second zone is 230°C, the temperature in the third zone is 240°C, and the temperature in the fourth zone is 250°C, temperature in zone 5 is 255°C, temperature in zone 6 is 255°C, temperature in zone 7 is 265°C, temperature in zone 8 is 255°C, temperature in zone 9 is 255°C, screw speed is 350r / min, residence time is 0.5 minutes . After extrusion, cooling, drying, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com