Impact-resistant and anti-blocking sewer cover macromolecular material

A polymer material, sewer technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems such as unfavorable rainwater drainage, large rainwater resistance, easy to cause blockage, etc., to reduce resistance, prolong service life, and increase drainage. the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

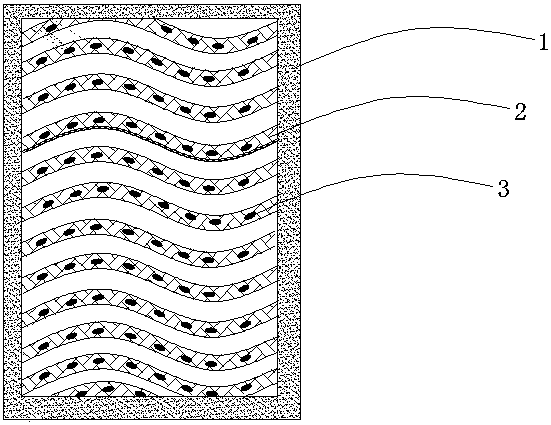

[0030] Specific embodiment 1: as figure 1 , figure 2 As shown, this embodiment discloses an impact-resistant and anti-blocking sewer cover, including a cover body 1, a barrier 2 in the middle of the cover body 1, and a friction block 3 provided on the barrier 2, the cover body 1, the barrier 2 and the friction block 3 For integral molding, the fence 2 is a wavy structure, the distance between two fences is 20 mm, the cover body is a rectangular structure, and the cross-section of the friction block 3 is a standard racetrack-shaped structure. The length of the friction block is 10mm, and the fence is provided with parallel concave or convex lines along the direction of the curve, and the distance between adjacent concave or convex lines is 5mm. Arranged in the direction of bending, the two ends of the friction block 3 are in a slope row structure, and the distance between two adjacent friction blocks on the same fence is 20mm.

[0031] The sewer cover disclosed in this embod...

specific Embodiment 3

[0046] Specific embodiment 3: as figure 1 , figure 2 As shown, this embodiment discloses an impact-resistant and anti-blocking sewer cover, including a cover body 1, a barrier 2 in the middle of the cover body 1, and a friction block 3 provided on the barrier 2, the cover body 1, the barrier 2 and the friction block 3 For integral molding, the fence 2 is a wave-shaped structure, the distance between two fences is 30mm, the cover body is a rectangular structure, and the cross-section of the friction block 3 is a standard racetrack-shaped structure. The length of the friction block is 25mm. Parallel dimples or embossments are arranged on the fence along the direction of the curve. The distance between adjacent dimples or embossments is 15mm. The friction block is Arranged in the direction of bending, the two ends of the friction block 3 are in a slope row structure, and the distance between two adjacent friction blocks on the same fence is 80mm.

[0047] The sewer cover discl...

specific Embodiment 4

[0054] Specific embodiment 4: as figure 1 , figure 2 As shown, this embodiment discloses an impact-resistant and anti-blocking sewer cover, including a cover body 1, a barrier 2 in the middle of the cover body 1, and a friction block 3 provided on the barrier 2, the cover body 1, the barrier 2 and the friction block 3 For integral molding, the fence 2 is a wavy structure, the distance between two fences is 20 mm, the cover body is a rectangular structure, and the cross-section of the friction block 3 is a standard racetrack-shaped structure. The length of the friction block is 40mm. Parallel dimples or embossments are arranged on the fence along the direction of the curve. The distance between adjacent dimples or embossments is 5mm. Arranged in the direction of bending, the two ends of the friction block 3 are in a slope row structure, and the distance between two adjacent friction blocks on the same fence is 100mm.

[0055] The sewer cover disclosed in this embodiment is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com