High-purity konjac mannan polysaccharide as well as preparation method and application thereof

A high-purity, mannanase technology, applied in fermentation and other directions, can solve the problems of long irradiation time, increased solubility, low purity, etc., achieves important economic and production value, proliferates vaginal lactic acid bacteria, and has the effects of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

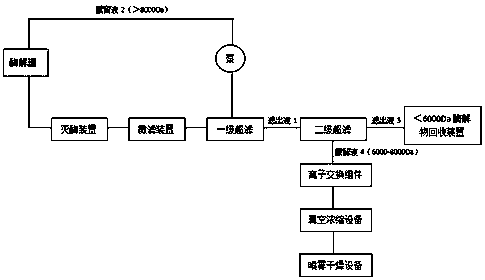

[0033] 20 as figure 1 Shown a kind of preparation method of mannose, comprises the following steps:

[0034] (1) Add 200kg of production water to the enzymolysis tank, control the temperature inside the enzymolysis tank to be 30-50°C, and put neutral β-mannanase into the enzymolysis tank (the amount of enzyme input is based on the amount of enzyme and konjac extract Powder mass ratio is 1:10-30), weigh 10kg of konjac fine powder, put it evenly into the enzymolysis tank with rapid and automatic detection material viscosity device, control the pH of the material in the enzymolysis tank to 6.0-7.5, with the enzyme As the hydrolysis time advances, the viscosity of the enzymolysis liquid drops rapidly. When the viscosity real-time detection device installed on the enzymolysis tank detects that the viscosity of the enzymolysis liquid reaches 300-400mpa.s, the enzyme is immediately deactivated, and the deactivation time is 20-30min. cool down;

[0035] (2) Microfiltration to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com