A kind of preparation method of mannan with specific molecular weight

A mannan, molecular weight technology, applied in biochemical equipment and methods, biological material sampling methods, bioreactors/fermenters for specific purposes, etc., can solve problems such as limited application, low efficiency, and residual degradation products, To achieve the effect of simplifying the production process, improving the enzymatic hydrolysis rate and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

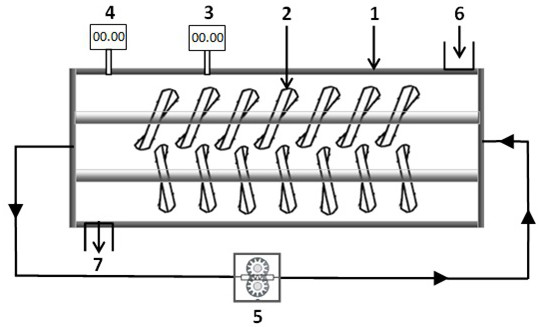

[0026] Inject 450kg of production water into the enzymolysis vessel, adjust the temperature in the enzymolysis vessel to 30°C, pH to 6.0-7.0, and put neutral β-mannanase into the enzymolysis vessel (the amount of enzyme input is based on the quality of the enzyme material). The ratio is 1:15), then weigh 50kg of konjac powder and put it into the enzymolysis container. Under the impetus of the twin-screw propulsion device and the gear pump, the enzymolysis cycle is carried out, and the vibration probe of the digital display device for molecular weight online detection is adjusted. The frequency is 80Hz and the amplitude is 1mm. As the enzymolysis proceeds, the viscosity of the enzymolysis solution gradually decreases. When the molecular weight online detection digital display device detects that the molecular weight of the enzymolysis solution is 100000-200000Da, the digital display temperature control system is set according to the setting. The program automatically activates t...

Embodiment 2

[0028] Inject 450kg of production water into the enzymolysis vessel, adjust the temperature in the enzymolysis vessel to 30°C, pH to 6.0-7.0, and put neutral β-mannanase into the enzymolysis vessel (the amount of enzyme input is based on the quality of the enzyme material). The ratio is 1:15), then weigh 50kg of guar gum, put it into the enzymolysis container, carry out cyclic enzymolysis under the impetus of twin-screw propulsion device and gear pump, and adjust the vibration of the digital display device for molecular weight online detection. The probe frequency is 80Hz and the amplitude is 1mm. As the enzymolysis progresses, the viscosity of the enzymolysis solution gradually decreases. When the molecular weight online detection digital display device detects that the molecular weight of the enzymolysis solution is 10000-12000Da, the digital display temperature control system will be set according to the setting. The predetermined program automatically activates the heating ...

Embodiment 3

[0030]Inject 450kg of production water into the enzymolysis vessel, adjust the temperature inside the enzymolysis vessel to 30°C, pH to 6.0-7.0, and put neutral β-mannanase into the enzymolysis vessel (the amount of enzyme input is based on the quality of the enzyme material). The ratio is 1:15), then weigh 50kg of locust bean gum and put it into the enzymolysis vessel. Under the impetus of the twin-screw propulsion device and the gear pump, carry out cyclic enzymolysis and adjust the vibration probe of the digital display device for molecular weight online detection. The frequency is 50Hz, and the amplitude is 2mm. As the enzymolysis proceeds, the viscosity of the enzymolysis solution gradually decreases. When the molecular weight online detection digital display device detects that the molecular weight of the enzymolysis solution is 3000-5000Da, the digital display temperature control system is set according to the setting. The program automatically activates the heating func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com