A kind of rod-shaped double metal oxide material and its preparation method

A double metal oxide, rod-shaped technology, applied in the direction of electrochemical generators, structural parts, electrical components, etc., can solve the problems of material structure collapse, rapid capacity decay, short cycle life, etc., to reduce mass transfer resistance and shorten reaction time period, reducing the effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) 0.6mmol CoCl 2 ·6H 2 O, 0.6mmol NiCl 2 ·6H 2 O. Add 0.6mmol 1,4-cyclohexanedioic acid and 0.6mmol 1,10-PHen into 16mL water, and sonicate for 20min;

[0031] 2) adjust the pH value of the above solution to 7 with a NaOH solution whose concentration is 6mol / L;

[0032] 3) Transfer the above solution to a 50mL polytetrafluoroethylene kettle, heat it with a microwave reactor, and react at the optimal temperature of 150°C for 30min;

[0033] 4) After the reaction, the solution was naturally cooled to room temperature, centrifuged at 7000r / min, washed with ethanol and water for 3 times, and then vacuum-dried at 60°C to constant weight to obtain a rose-colored powder;

[0034] 5) Calcining the obtained rose-colored powder in the air to obtain a black powder, which is the bimetallic oxide material B1 with a rod-like structure, the calcination temperature is 600°C, the calcination time is 2h, and the heating rate is 2°C / min

example 1

[0035] The test results of Example 1 are as follows:

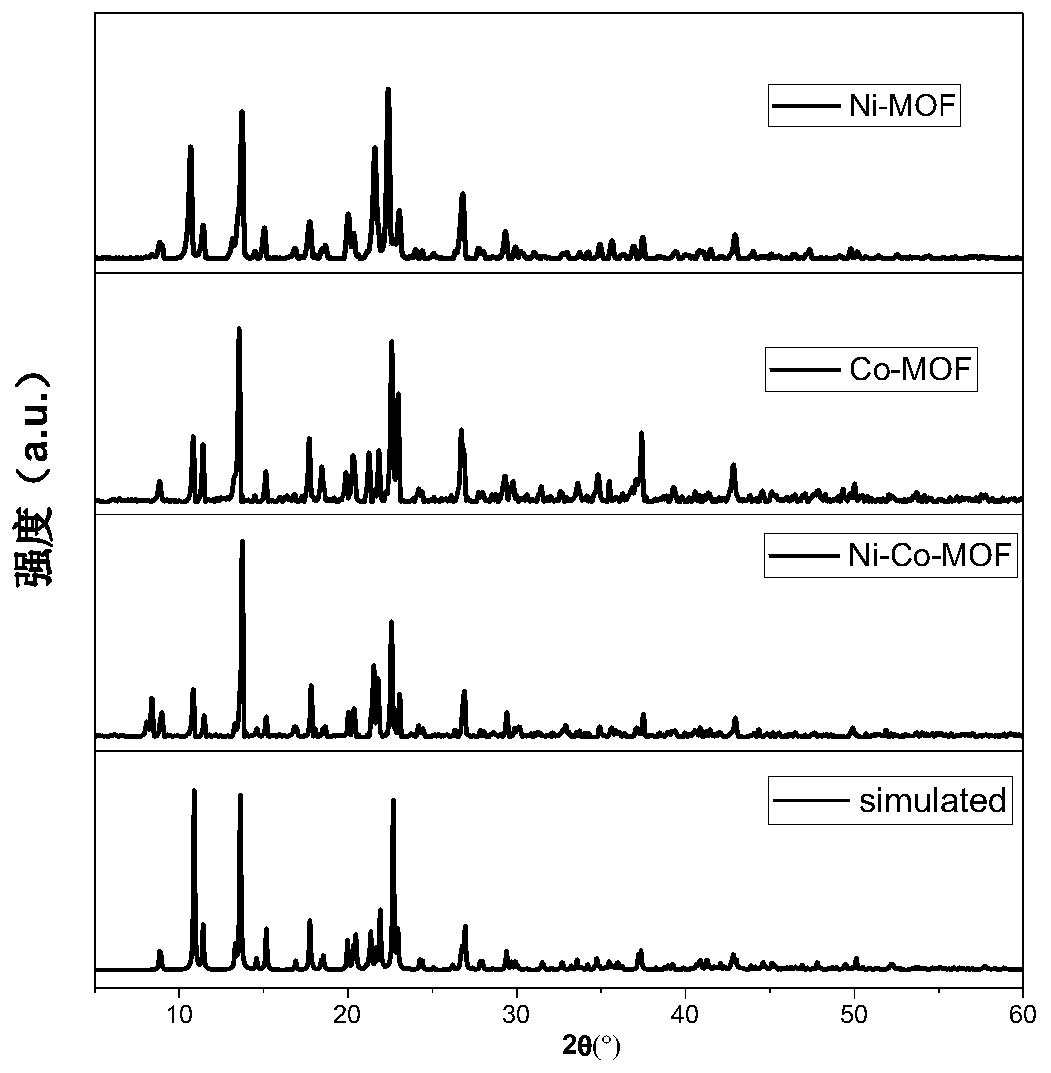

[0036] (1) By performing X-ray diffraction spectrum detection on the precursor of B1, the results are shown in figure 1 ,Will figure 1 Compared with the crystal diffraction data, it can be seen that the synthesized precursor MOFs material is basically consistent with the crystal diffraction data, which preliminarily shows that the prepared MOFs are materials containing both Ni and Co metals. The molecular formula of the material is [M 2 (PHen) 2 (e,a-cis-1,4-chdc) 2 (H 2 O) 2 ] n , wherein M=Co, Ni, PHen=1,10-PHenanthroline, chdc=cyclohexanedicarboxylate;

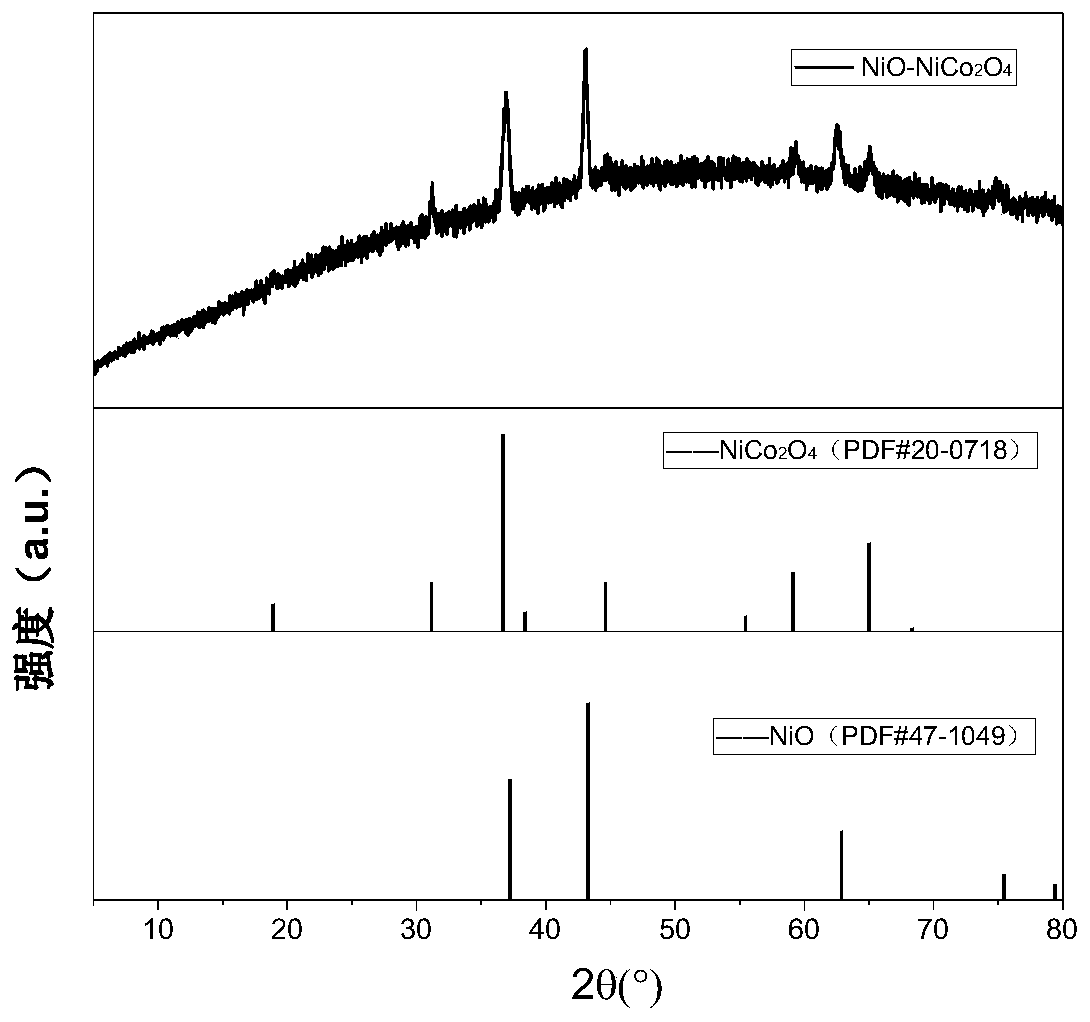

[0037] (2) By carrying out X-ray diffraction spectrum detection on B1, the results are shown in figure 2 , by comparison, it can be seen that the material is compatible with NiO (PDF#47-1049) and NiCo 2 o 4 (PDF#20-0718) The diffraction peaks are consistent, indicating that the material is NiO-NiCo 2 o 4 ;

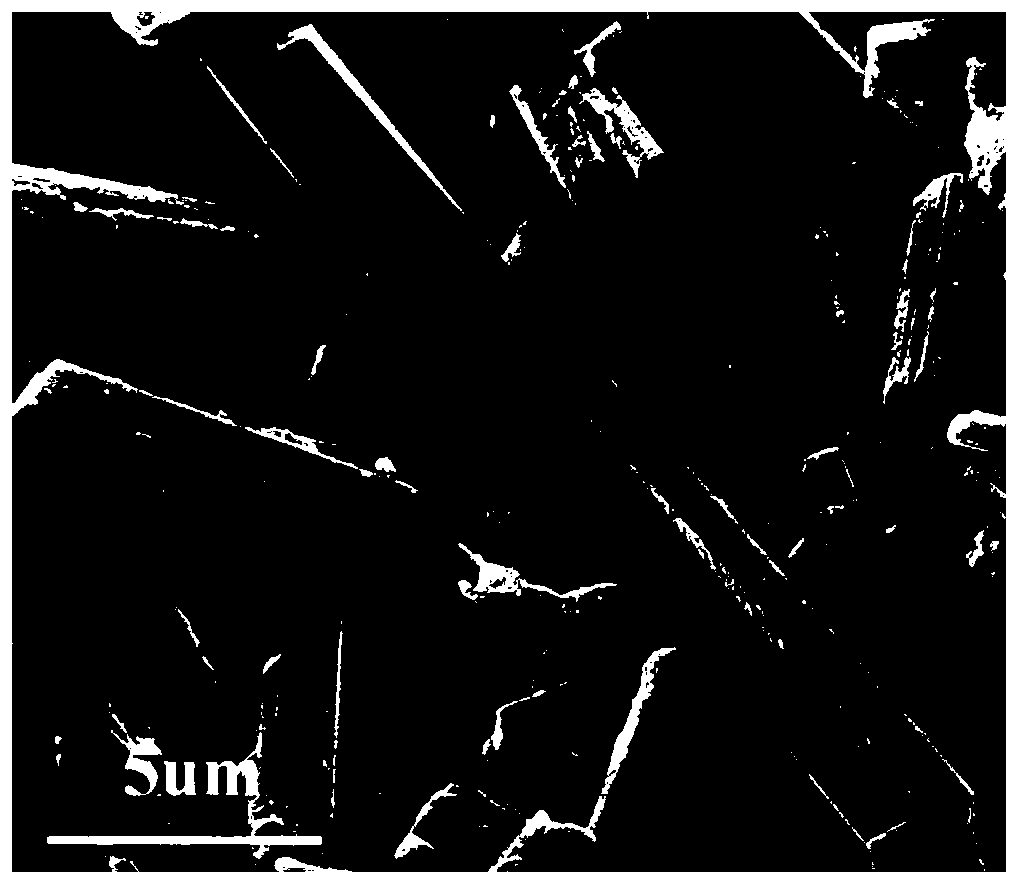

[0038] (3) Through the scanning electron microsco...

Embodiment 2

[0043] Prepare the NiO-NiCo of rod-like structure according to the method for embodiment 1 2 o 4 Material B2, the different steps are 1) with 0mmol CoCl 2 ·6H 2 O, 0.6mmol NiCl 2 ·6H 2 O, 0.6mmol of 1,4-cyclohexanedioic acid and 0.6mmol of 1,10-PHen were added to 16mL of water, and sonicated for 30min;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com