Structure of negative current collector of liquid metal battery and assembly method of structure

A technology of liquid metal batteries and current collectors, which is applied in the direction of electrode carriers/collectors, secondary batteries, circuits, etc., to achieve the effects of optimizing reaction rate and current collection efficiency, reducing force deformation, and avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

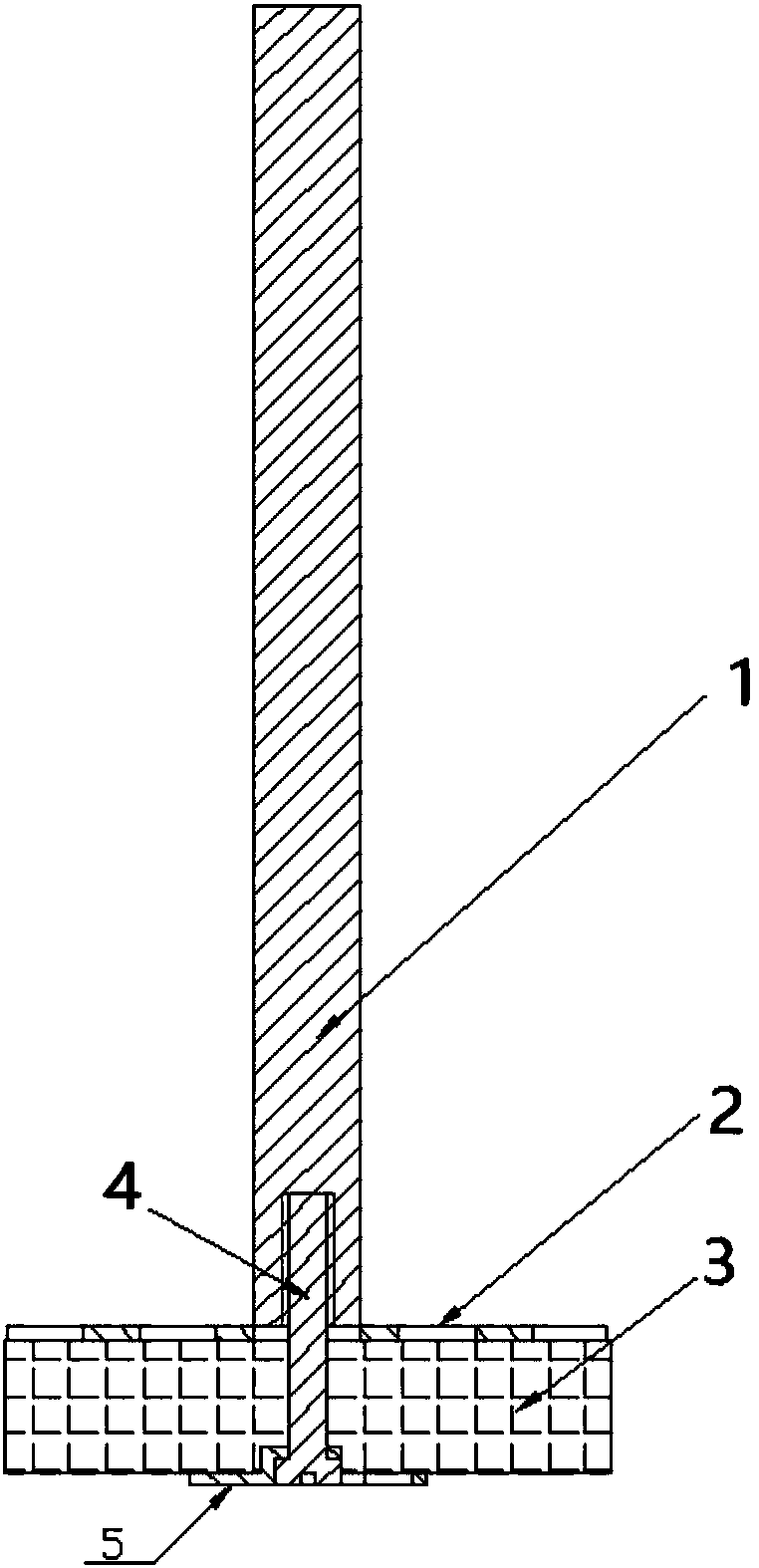

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The device structure and method are respectively described below:

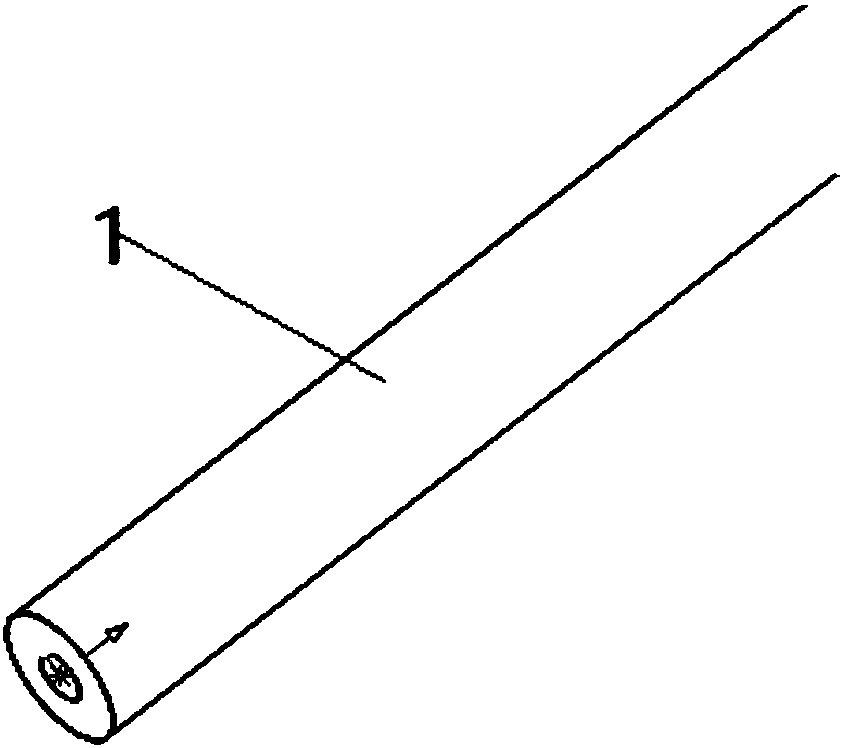

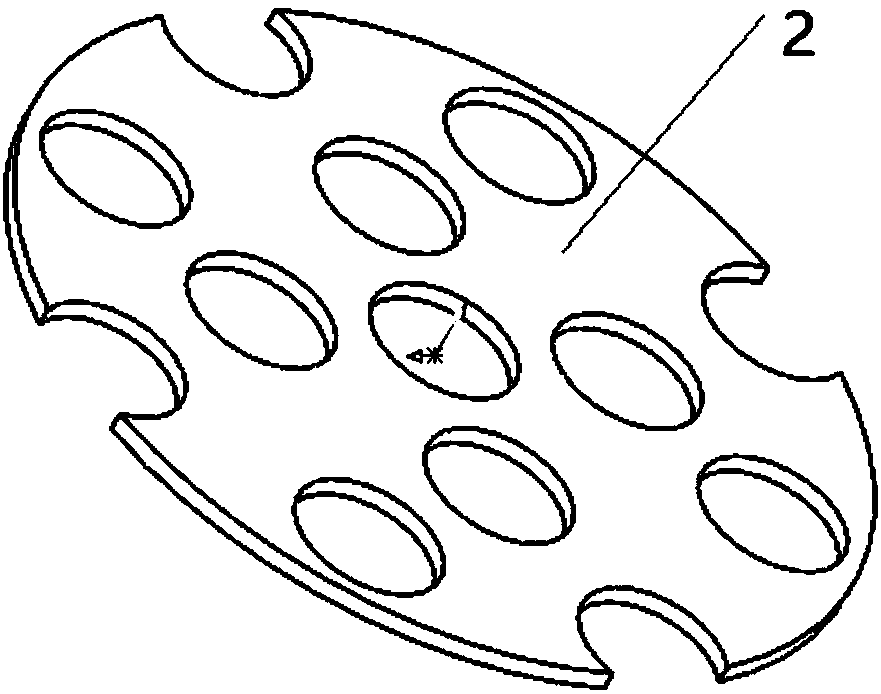

[0033] see Figure 1-5 , the present invention is a liquid metal battery negative current collector structure, including a current collector rod 1 with internal screw holes, porous metal plate 2, foam metal 3, screw 4 and trident gasket 5. The inner screw hole of the collector rod 1 matches the screw 4; the outer diameter of the collector rod 1 matches the diameter of the center circle of the porous metal plate 2; the diameter of the cylindrical channel in the foam metal 3 matches the screw 4; The diameter of the round hole matches the screw, and the groove matches the nut.

[0034] Among them, the collector rod 1, the porous metal plate 2, the foam metal 3, the screw 4 and the trident gasket 5 are all designed coaxially; the collector rod 1, the porous metal plate 2, the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com