Fuel cell stack structure

A fuel cell stack and electric stack technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of uneven internal resistance of the stack, inconsistent reaction efficiency, and large heat dissipation at the terminals, so as to ensure normal operation. Working conditions, ease of automated production, and reasonable packaging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

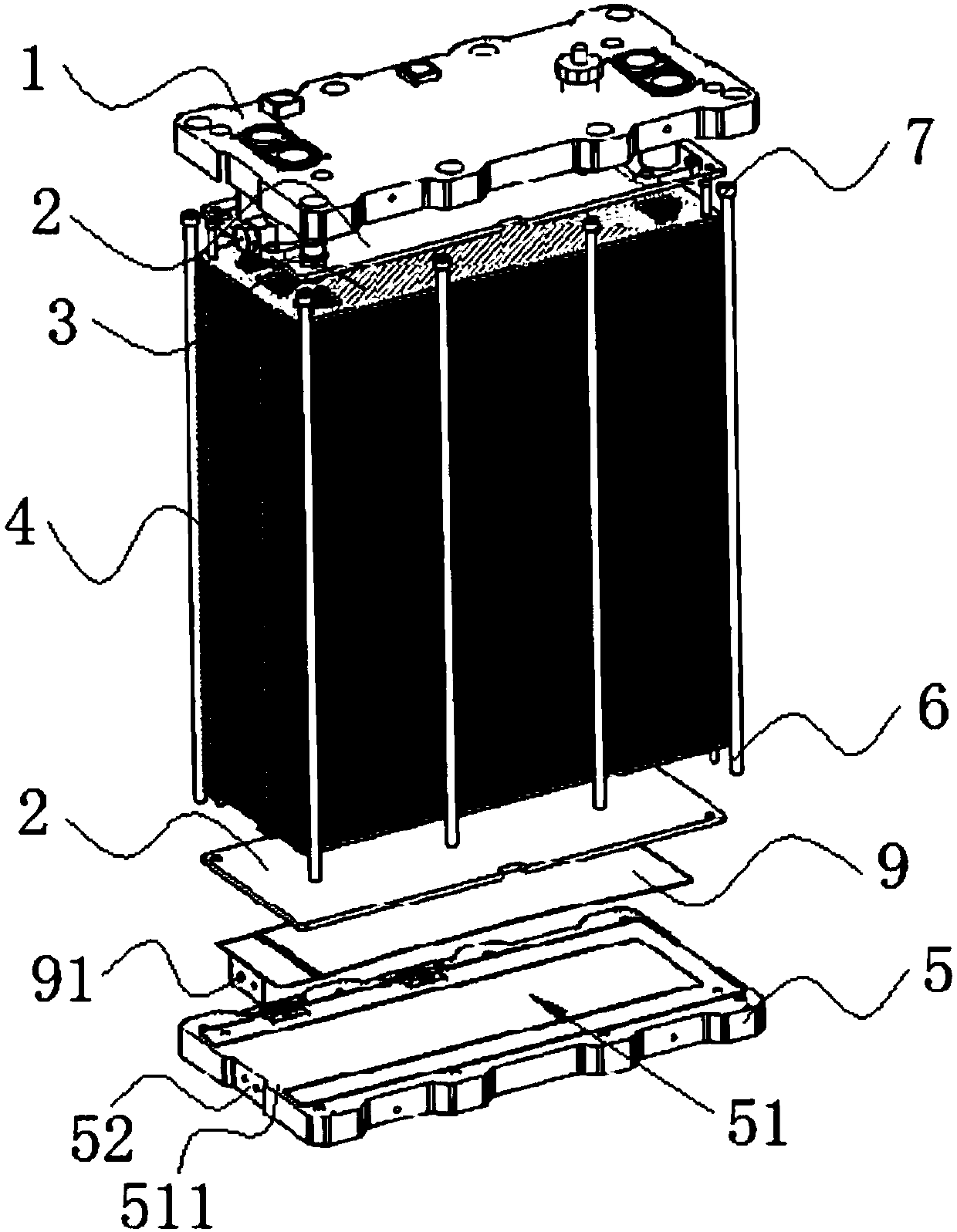

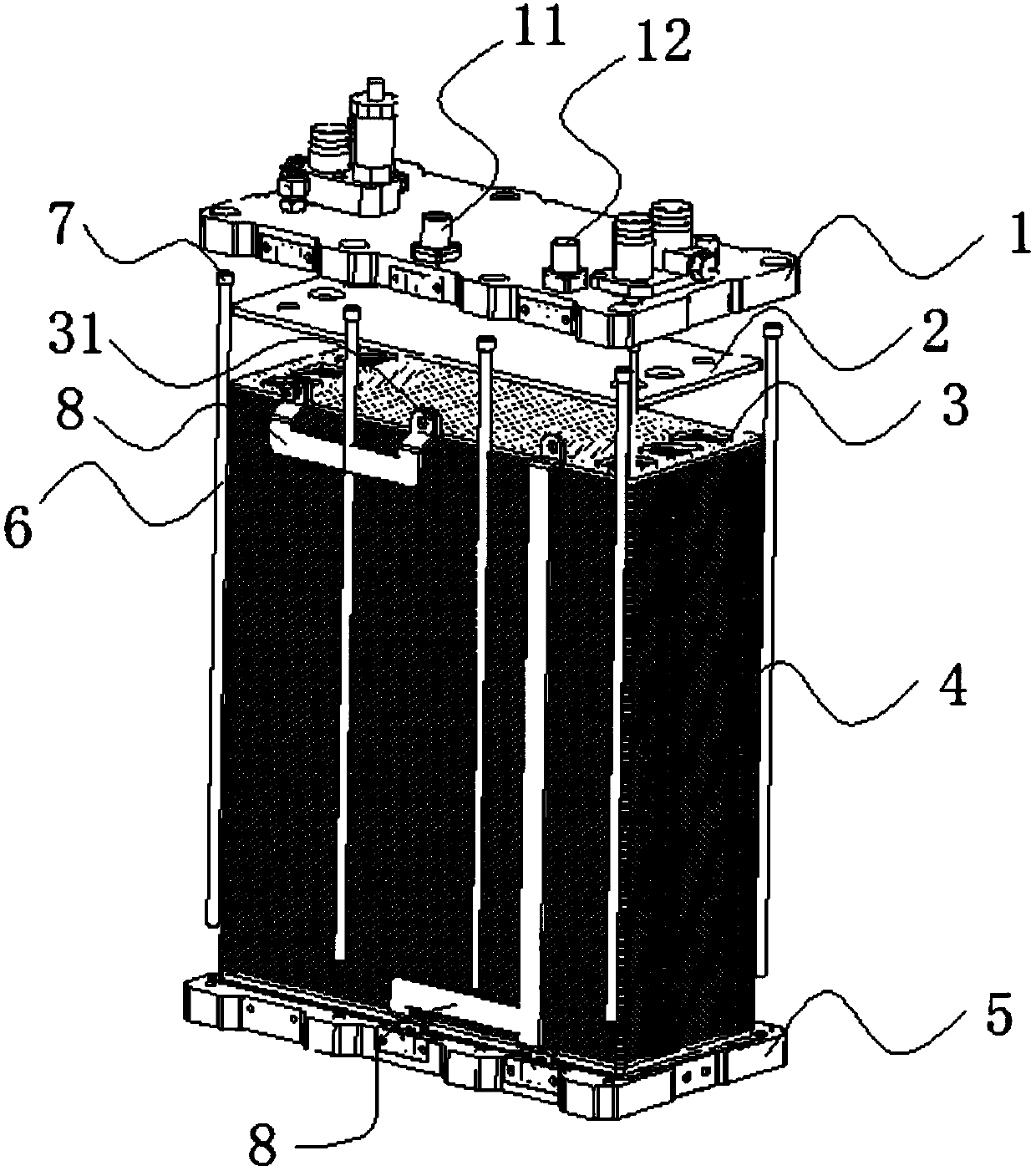

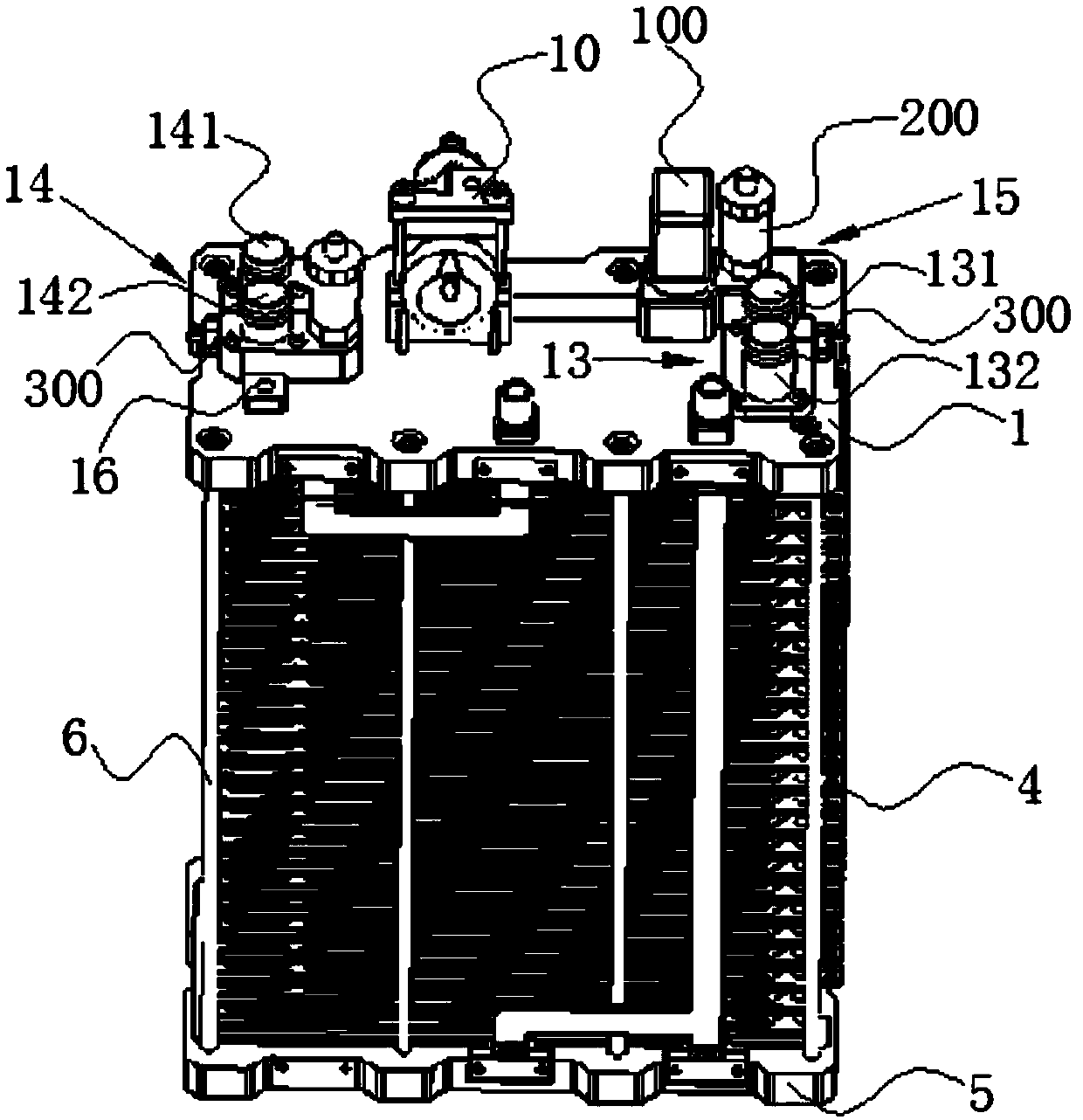

[0035] Embodiment 1: a fuel cell stack structure, such as Figure 1-Figure 4 As shown, it includes an upper end plate 1, an insulating plate 2, a collector plate 3, a stack body 4 and a lower end plate 5, the upper end plate 1 and the lower end plate 5 are parallel to each other, and the upper end plate 1 and the lower end plate 5, two insulating plates 2 are arranged between them, two collector plates 3 are arranged between the two insulating plates 2, and the stack body is arranged between the two collector plates 3 4;

[0036] It also includes several insulating fixing rods 6 located on the periphery of the stack body, the two ends of the insulating fixing rods 6 are respectively connected to the nuts 7 of the upper end plate 1 and the nuts 7 of the lower end plate 5, and the nuts of the nuts 7 The inner surface has internal threads matching the external threads at both ends of the insulating fixing rod 6;

[0037] The upper surface of the lower end plate 5 has a concave ...

Embodiment 2

[0050] Embodiment 2: a fuel cell stack structure, such as Figure 1-Figure 5 As shown, the structure of the second embodiment is similar to that of the first embodiment, the difference is that the elastic support is a spring 400, and the center of the bottom surface of the groove is provided with a positioning hole 512 matching the spring , one end of the spring is fixed in the positioning hole, and the other end of the spring is in contact with the lower surface of the insulating plate.

[0051] The working principle of the present invention is as follows: the two ends of the insulating fixing rod of the present invention are respectively connected with the nuts of the upper end plate and the nuts of the lower end plate, the packaging structure is reasonable, the cost is low, and it is convenient for automatic production. The upper surface of the lower end plate has a concave groove The groove and the elastic support between the groove and the insulating plate provide uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com