Rapid evaluation method for cycle performance of graphite negative electrode material for lithium battery

A graphite negative electrode and cycle performance technology, applied in the field of electrochemistry, can solve the problems of increasing equipment cost, occupying test equipment, and large energy consumption, and achieves the effects of strong reliability, reduced energy consumption, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

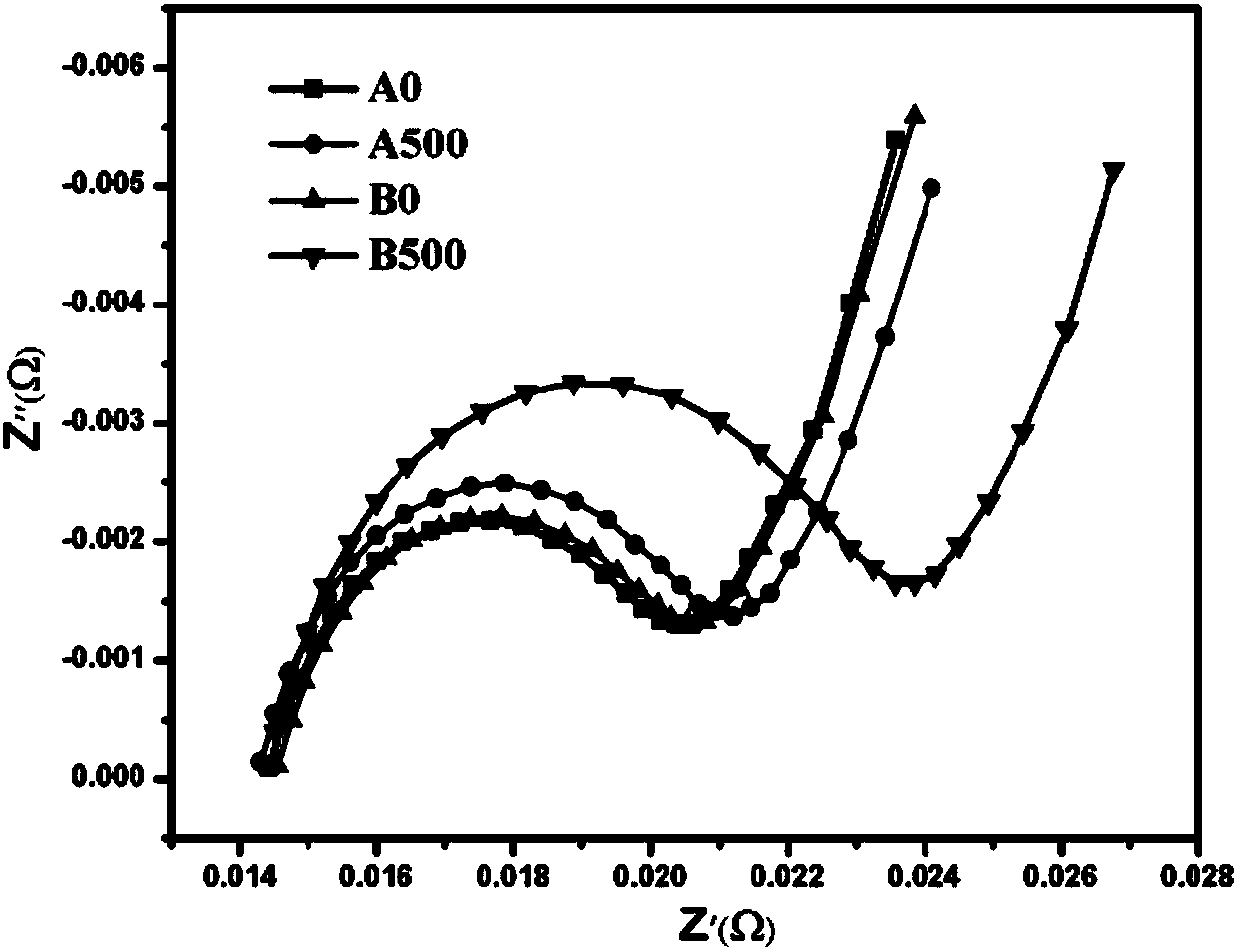

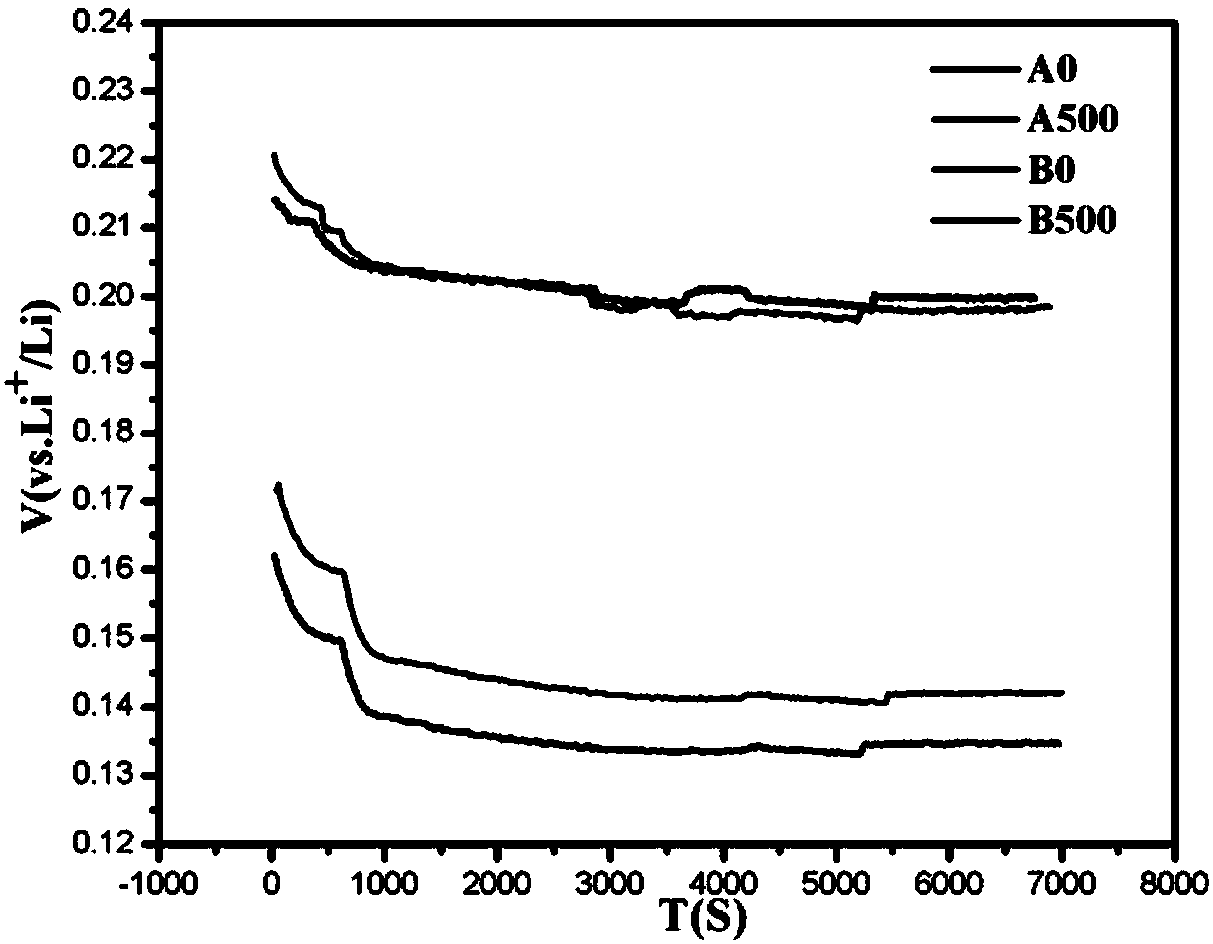

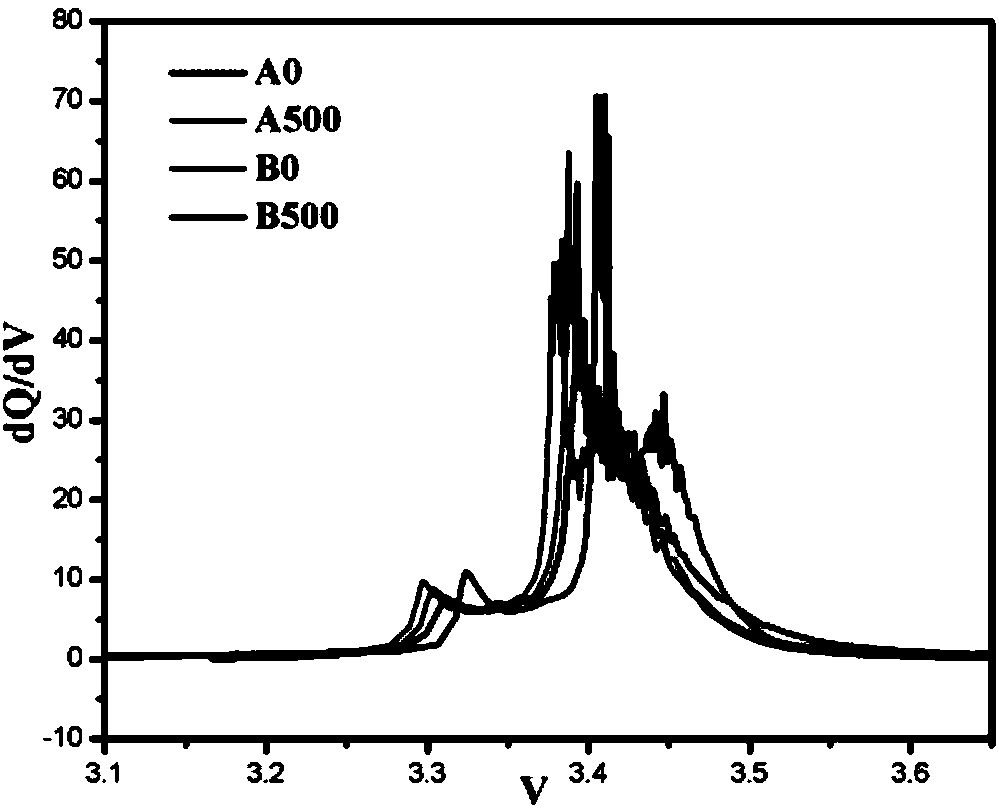

[0033] This example provides a rapid evaluation method for the cycle performance of graphite anode materials for lithium batteries, using electrochemical impedance spectroscopy (EIS), full battery three-electrode testing, and dQ / dV-V curves based on capacity increments, combined with local SOC cycles method to realize rapid evaluation of the cycle performance of graphite anode materials, the specific steps are as follows:

[0034] 1. Prepare soft-pack 4360143 laminated batteries. The positive electrode is lithium ferrous phosphate (LFP) as an example, and the negative electrode is graphite negative electrode, which is two kinds of graphite, A and B, respectively. The capacity and first-time efficiency are equivalent. At 340mAh / g, the first-time efficiency of the full battery is 90%; the three electrodes of the full battery are made: the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com