Collision type shell breaking machine

A shell breaking machine and impact type technology, which is applied in the field of agricultural machinery, can solve the problems of difficulty in adjusting the gap between the two pressure rollers, adhesion of fruit shells and their debris, high seed damage rate, etc., and achieve high shell breaking efficiency, low cost, The effect of increasing the shell breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

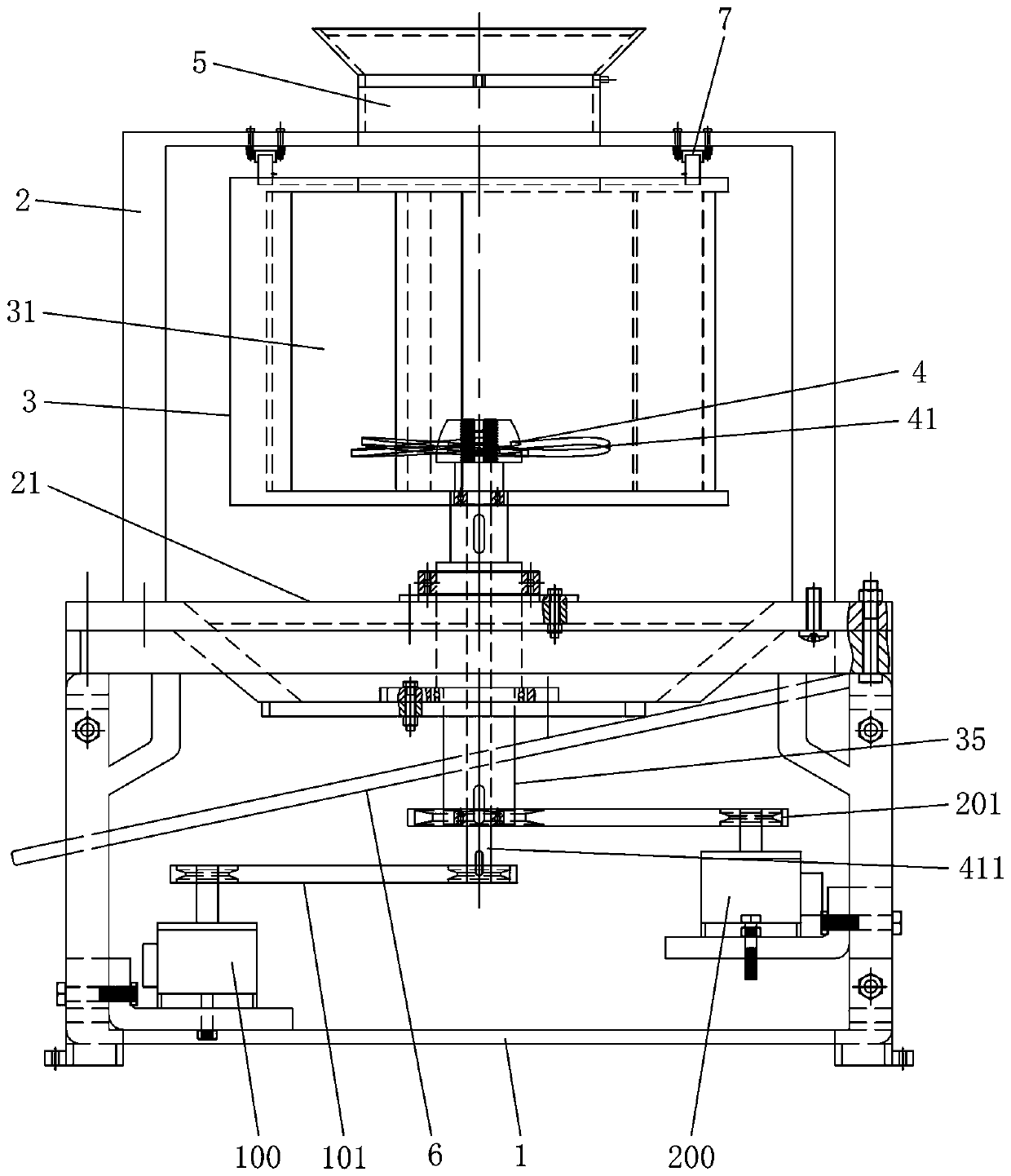

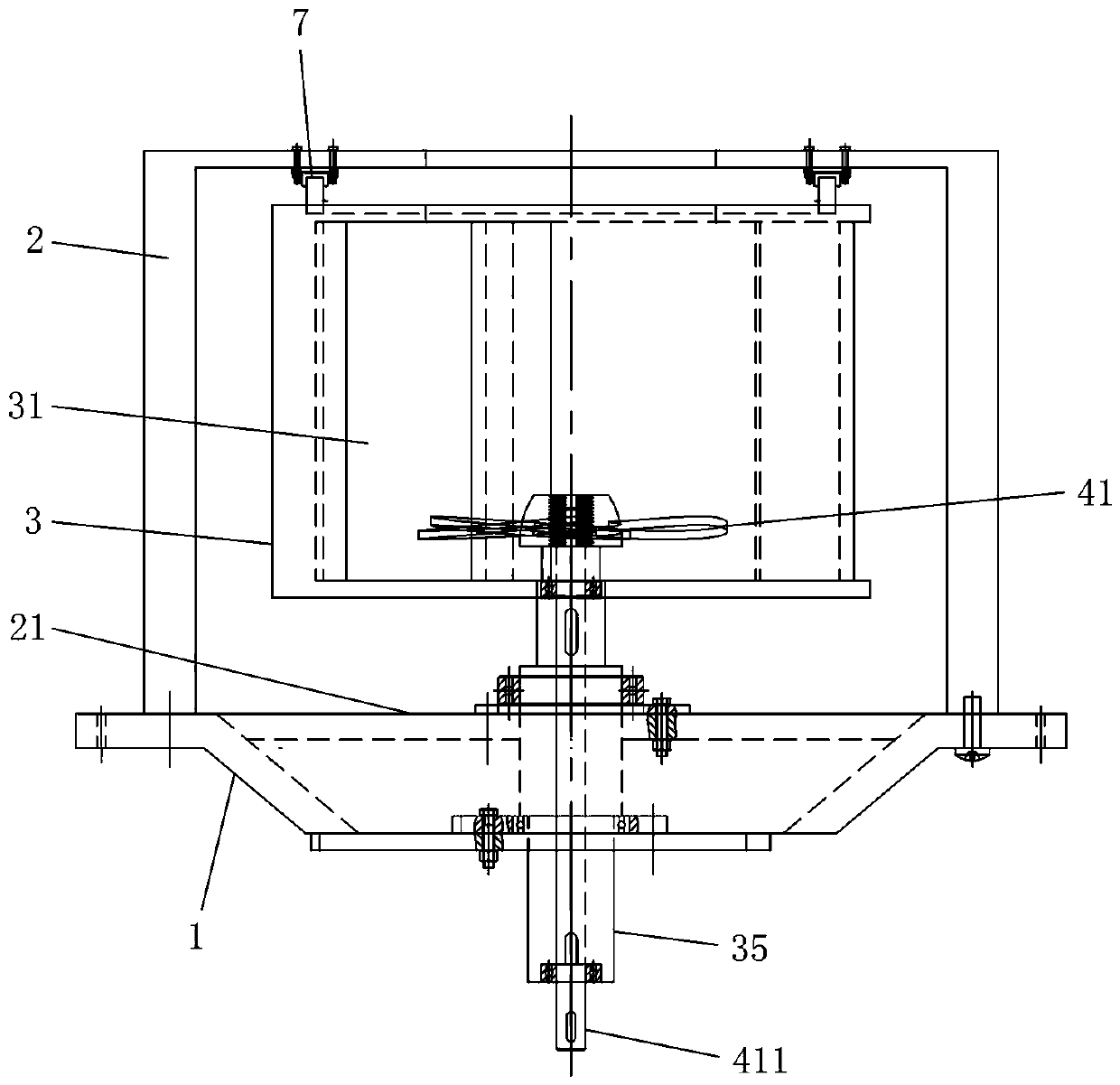

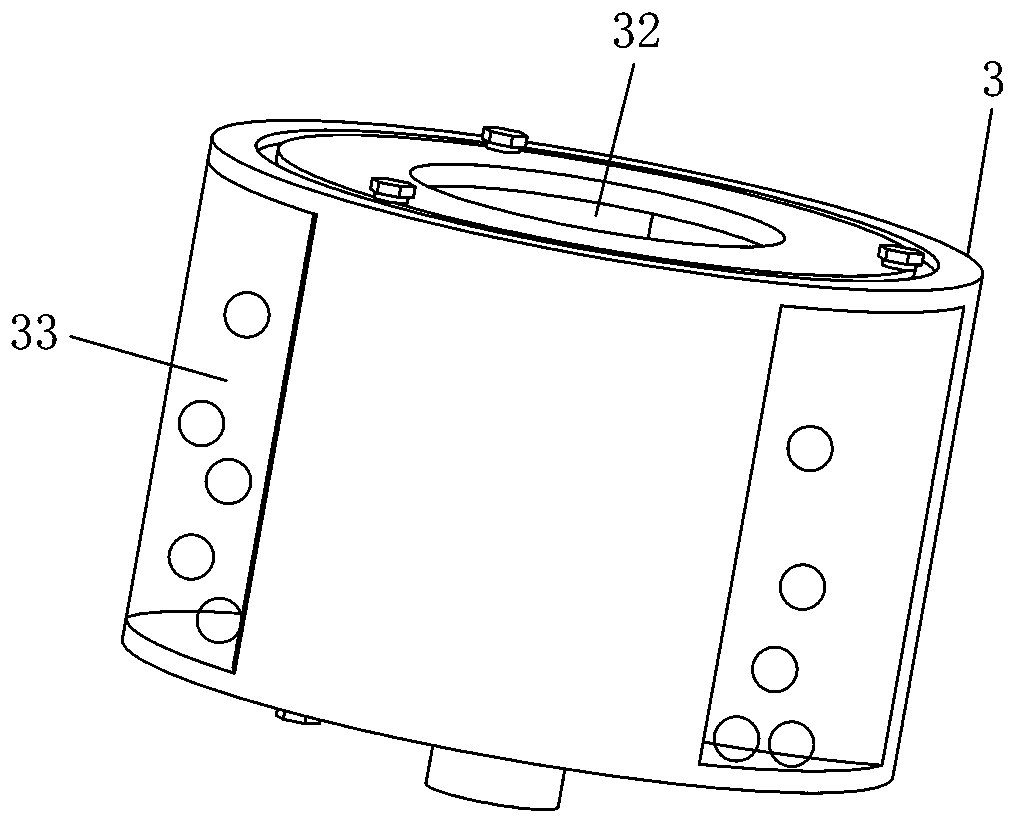

[0027] Such as Figure 1 to Figure 4 As shown, the impact type shell breaking machine of this embodiment includes a frame 1, an outer shell 2 installed on the frame 1, and an inner barrel 3 installed in the outer shell 2. The inner barrel 3 has an inner cavity 31 and a The material inlet 32, the bottom of the inner cavity 31 is installed with a rotary drive device 4 for generating centrifugal force of the material and projecting to the side walls of the inner cavity 31, and the surrounding side walls of the inner cavity 31 are provided with a number of The discharging port 33 in the shell 2 is provided with a material outlet 21 at the bottom of the shell 2. The impact type shell breaker also includes a feeding device 5 for adding materials to the inner cavity 31. When working, the feeding device 5 is used to add the material into the inner cavity 31...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com