A kind of highly dispersed thick flaky α-alumina micropowder and its preparation method

A micro-powder of alumina, high-dispersion technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., to achieve the effect of low price, simple preparation process, and smooth and smooth products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of highly dispersed thick flaky α-Al 2 o 3 The preparation method of micropowder specifically comprises the steps:

[0033] (1) Take 1.2g industrial AlOOH and 0.24g NH 4 BF 4 Grind in an agate mortar for 1 h to mix well, then transfer to a corundum crucible;

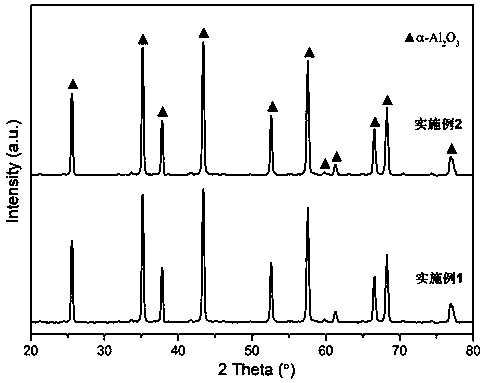

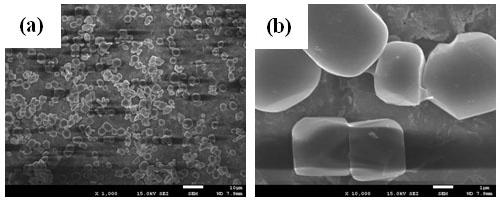

[0034] (2) Place the corundum crucible in a muffle furnace and calcinate according to the following heating program: raise the temperature to 300°C at a heating rate of 10°C / min, then raise the temperature to 1000°C at a heating rate of 5°C / min, and then increase the temperature at 2°C / min Raise the temperature to 1450°C at a heating rate of min, keep it at 1450°C for 3 hours, and cool naturally to room temperature to obtain α-Al 2 o 3 Micropowder, its appearance is like figure 1 as shown, figure 1 All diffraction peaks in 2 o 3 The characteristic peaks are consistent with each other, and there are no other impurity peaks, indicating that the obtained sample is pure phase α-Al 2 o 3 .

[0035] C...

Embodiment 2

[0037] A kind of highly dispersed thick flaky α-Al 2 o 3 The preparation method of micropowder specifically comprises the steps:

[0038] (1) Take 1.2g bommite and 0.235g NH respectively 4 BF 4 and 0.005g NH 4 F ground in an agate mortar for 1 h, then transferred to a corundum crucible;

[0039] (2) Place the corundum crucible in a muffle furnace and calcinate according to the following heating program: raise the temperature to 300°C at a heating rate of 10°C / min, then raise the temperature to 1000°C at a heating rate of 5°C / min, and then increase the temperature at 2°C / min Raise the temperature to 1450°C at a heating rate of min, keep it at 1450°C for 3 hours, and cool naturally to room temperature to obtain α-Al 2 o 3 Micropowder, its XRD test result is as follows figure 1 As shown, it was confirmed that the obtained sample was pure phase α-Al 2 o 3 .

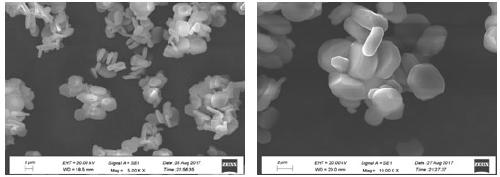

[0040] Calcined α-Al in a crucible 2 o 3 The micropowder sample was transferred to an agate mortar and ground t...

Embodiment 3

[0042] A kind of highly dispersed thick flaky α-Al 2 o 3 The preparation method of micropowder specifically comprises the steps:

[0043] (1) Take 1.2g industrial AlOOH and 0.0012g NH 4 BF 4 Grind in an agate mortar for 3h to mix well, then transfer to a corundum crucible;

[0044] (2) Place the corundum crucible in a muffle furnace and calcinate according to the following heating program: heat up to 300°C at a heating rate of 5°C / min, then rise to 1000°C at a heating rate of 3°C / min, and then heat up to 1000°C at a heating rate of 2°C / min. Raise the temperature to 1100°C at a heating rate of min, keep it at 1100°C for 5 hours, and cool naturally to room temperature to obtain α-Al 2 o 3 Micronized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com