Ultralight styrene-ethylene/butylene-styrene block copolymer (SEBS) modified material and preparation method thereof

A technology of modified materials and thermoplastic elastomers, which is applied in the field of ultra-light SEBS modified materials and its preparation, can solve the problems of poor compression set, poor fluidity, high density, etc., and achieve increased hardness, improved melt index, and enhanced interface bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

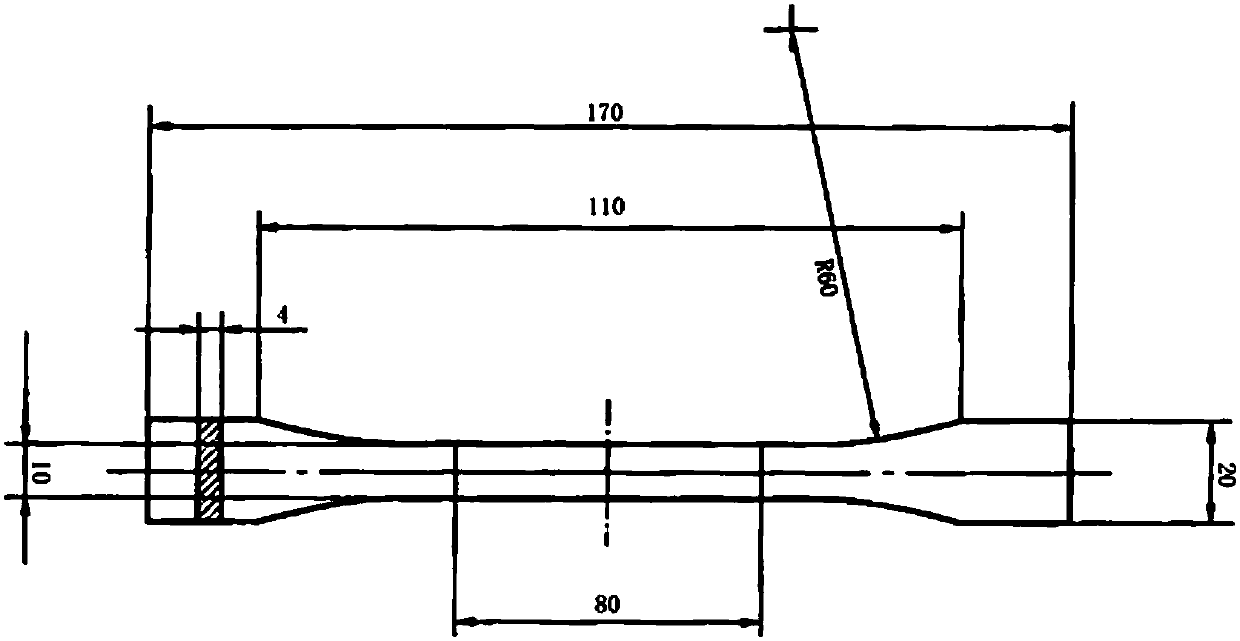

Image

Examples

Embodiment 1

[0038] An ultra-light SEBS modified material, the components are calculated by weight: 100 parts of SEBS, 100 parts of naphthenic oil, 30 parts of polypropylene, 5 parts of hollow glass microspheres, 0.05 parts of silane coupling agent KH-550, Titanate coupling agent 201 0.05 part, antioxidant 1010 0.1 part.

[0039]The preparation method of above-mentioned ultra-light SEBS modified material, comprises the steps:

[0040] (1) Pre-mix the SEBS material and naphthenic oil in proportion, put it into a high-speed mixer and mix it at 70°C for 30-50 minutes, mix it evenly and place it at room temperature for more than 48 hours to obtain an oil-extended SEBS thermoplastic elastomer;

[0041] (2) Put the hollow glass microspheres into an electrothermal constant temperature blower dryer and dry them at 80°C for 3 hours, dilute the silane coupling agent KH-550 and titanate coupling agent 201 with ethanol with a volume concentration of 90% to 3wt% The solution; the diluted coupling agen...

Embodiment 2

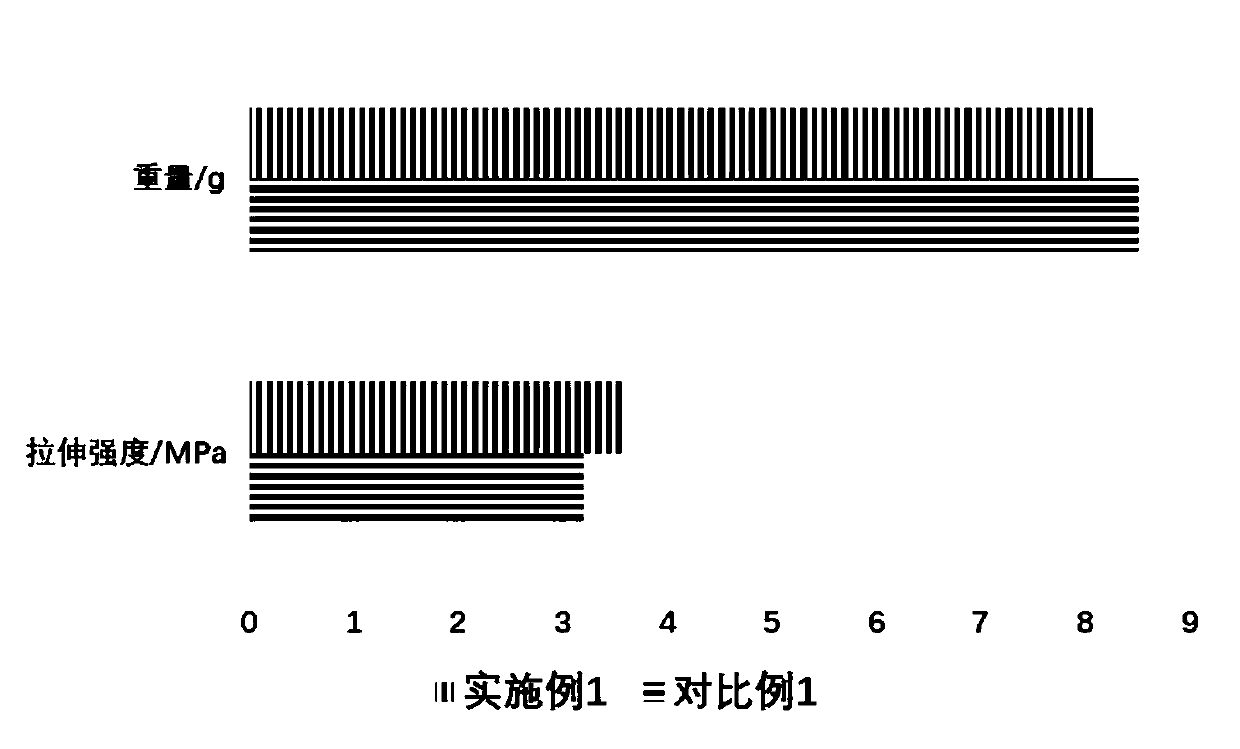

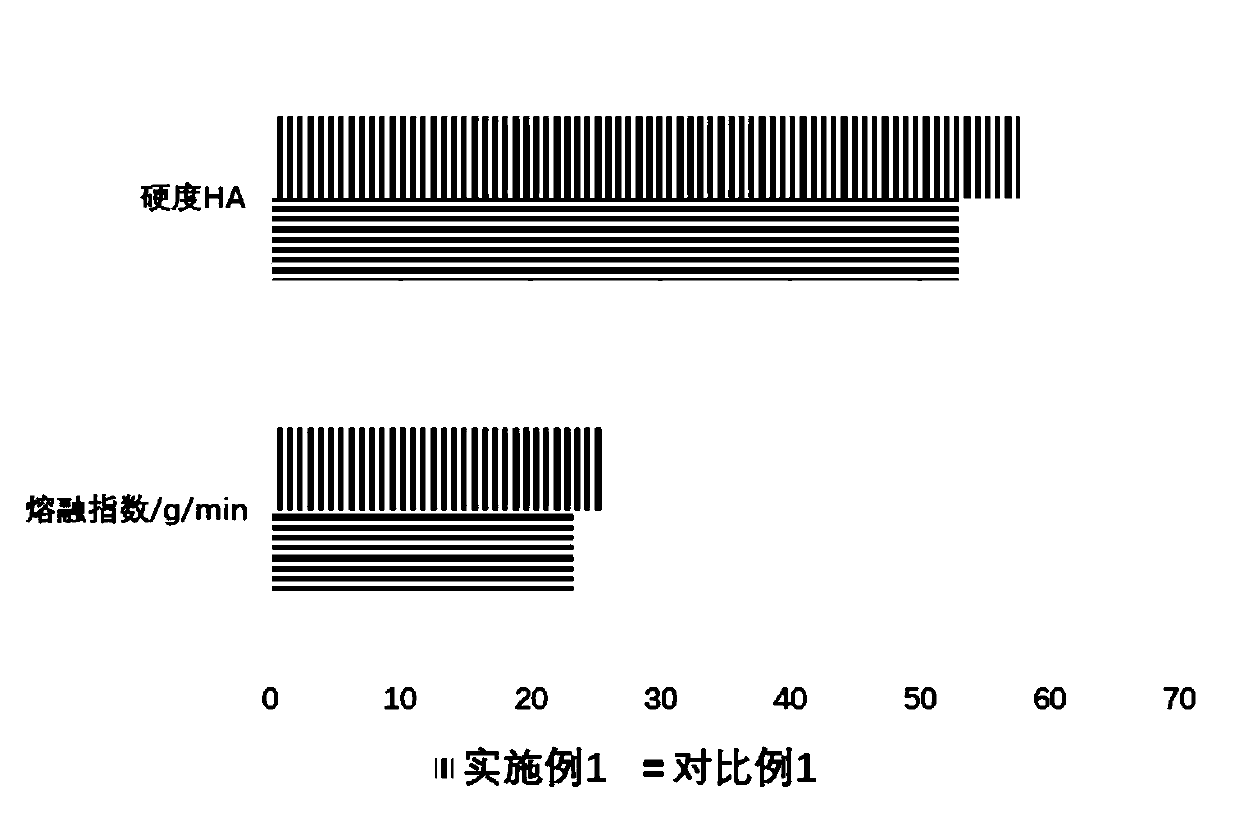

[0047] An ultra-light SEBS modified material, the components are calculated by weight: 100 parts of SEBS, 100 parts of naphthenic oil, 30 parts of polypropylene, 10 parts of hollow glass microspheres, 0.05 parts of silane coupling agent KH-550, Titanate coupling agent 201 0.05 part, antioxidant 1010 0.1 part. The preparation method is the same as in Example 1, and the ultra-light SEBS modified material prepared in this example and Comparative Example 1 are tested. For specific data, see Figure 4 , Figure 5 The test results show that the weight of the ultra-light SEBS modified material prepared in this embodiment is reduced by 10.7%, the tensile strength is increased by 5.6%, the hardness is increased by 11.2%, and the melt index is increased by 4.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com