A preparation process of cermet powder for thermal spraying

A preparation process and cermet technology, which is applied in metal material coating process, metal processing equipment, coating, etc., can solve the problem of incompatibility between spray deposition rate and coating density, and achieve high density and good comprehensiveness effect, the effect of improving the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

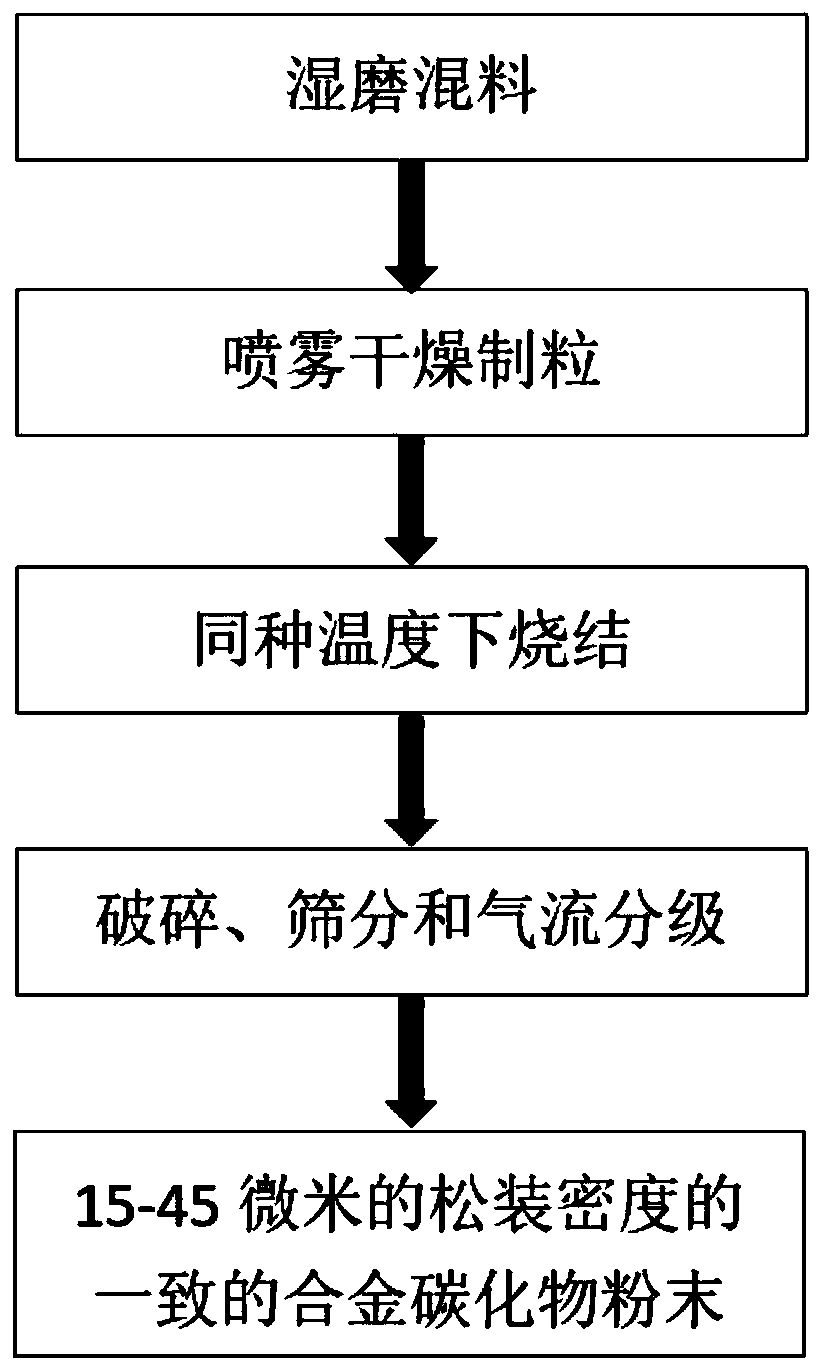

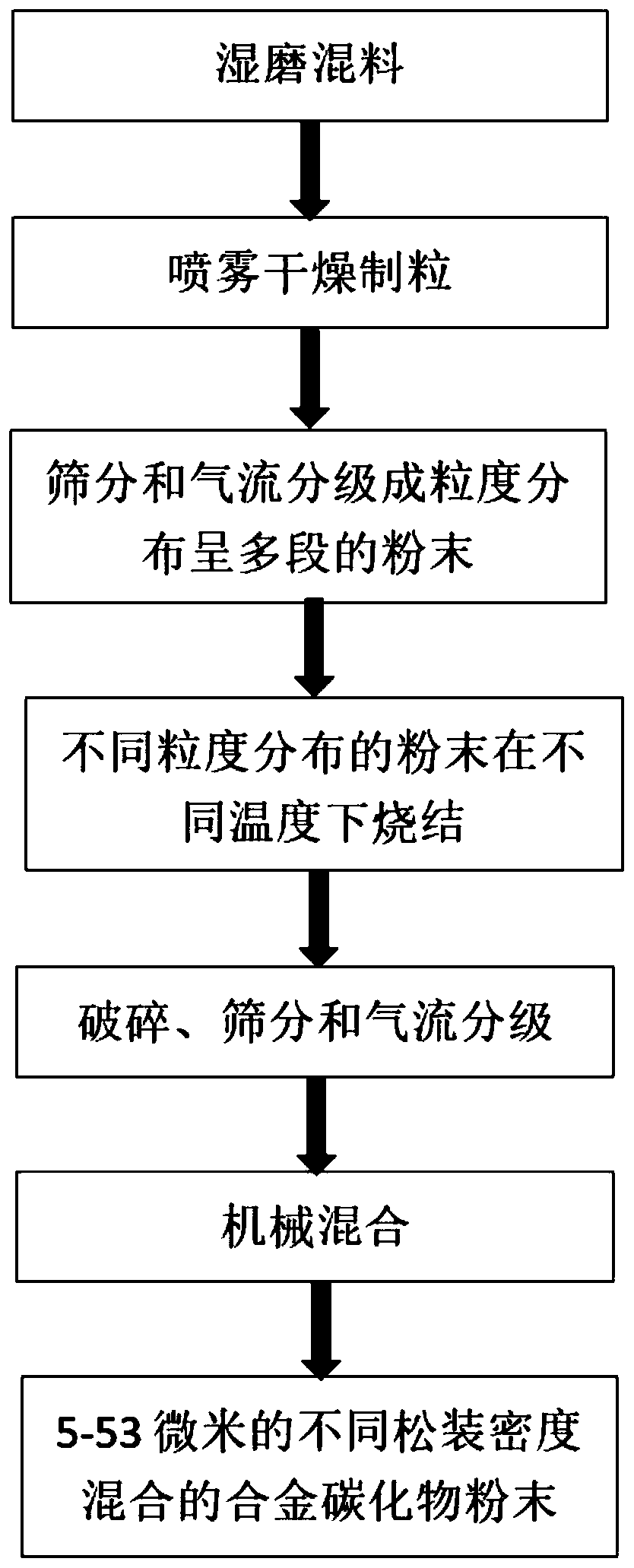

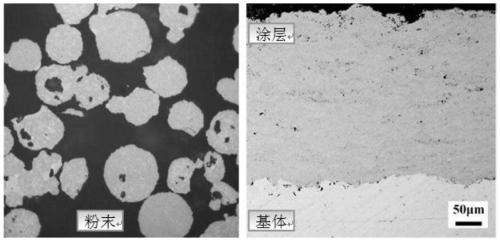

Method used

Image

Examples

Embodiment 1

[0068] (1) Add 88wt.% WC (particle size ~2.5 microns) and 12wt.% Co powder (1-3 microns particle size) to the ball milling barrel respectively, and add 88 wt.% of the total mass of powder raw materials to the barrel 23wt.% of deionized water and 2wt.% of polyvinyl alcohol were added into WC-Co cemented carbide balls according to the ball-to-material ratio of 6:1, and ball milled for 30 hours to obtain slurry P1.

[0069] (2) The slurry P1 is gradually introduced into the top container of the spray drying tower, and subjected to centrifugal spray drying to obtain spherical WC-12Co powder P2 with different particle sizes.

[0070] (3) The P2 powder is classified into two kinds of WC-12Co powders P3 and P4 with a particle size of 5-25 μm and 25-53 μm by sieving and airflow classification.

[0071] (4) P3 powder was sintered at 1195°C to obtain high-density P5 powder, and P4 powder was sintered at 1175°C to obtain low-density P6 powder. The sintering furnace used can be with redu...

Embodiment 2

[0077](1) Add 88wt.% WC (particle size ~2.5 microns) and 12wt.% Co powder (1-3 microns particle size) to the ball milling barrel respectively, and add 88 wt.% of the total mass of powder raw materials to the barrel 23wt.% of deionized water and 2wt.% of polyvinyl alcohol were added into WC-Co cemented carbide balls according to the ball-to-material ratio of 6:1, and ball milled for 30 hours to obtain slurry P1.

[0078] (2) The slurry P1 is gradually introduced into the top container of the spray drying tower, and subjected to centrifugal spray drying to obtain spherical WC-12Co powder P2 with different particle sizes.

[0079] (3) The P2 powder is classified into three kinds of WC-12Co powders P3, P4 and P5 with particle sizes of 5-20 microns, 20-38 microns and 38-53 microns by sieving and airflow classification.

[0080] (4) P3 powder was sintered at 1195°C to obtain high-density P6 powder, and P4 powder was sintered at 1185°C to obtain medium-density P7 powder. P5 powder w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com