Hydrophilic color fixing agent for cotton fabric and preparation method thereof

A technology of cotton fiber fabric and hydrophilic type, which is applied in the field of hydrophilic color fixing agent and its preparation, can solve the problems of not affecting the hygroscopicity and the color fixing effect, and achieve the improvement of wet treatment fastness and color fixing effect Good, good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

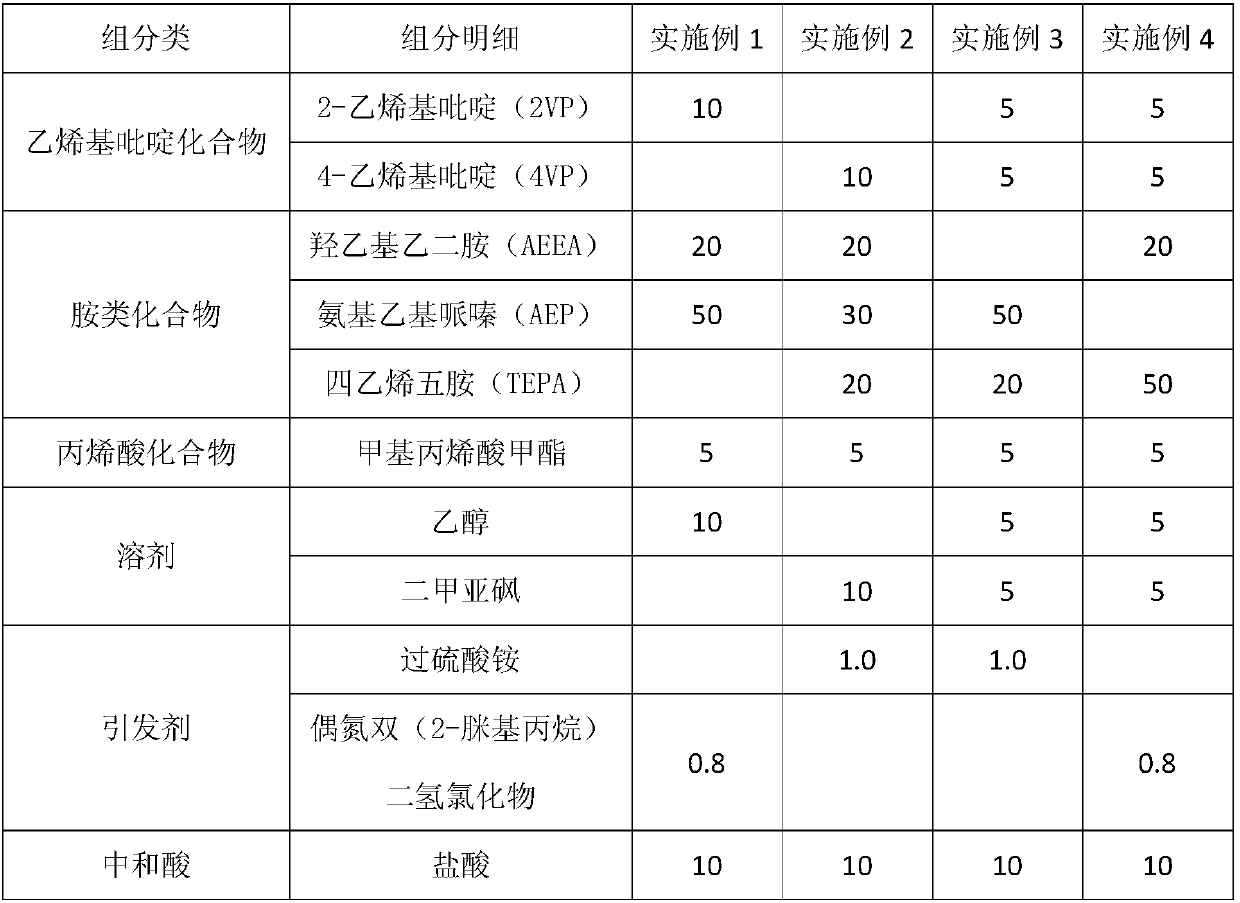

Embodiment 1

[0035] A hydrophilic color fixing agent for cotton fiber fabrics, which is polymerized by the following components by mass: 10 parts of 2-vinylpyridine (2VP), 20 parts of hydroxyethylethylenediamine (AEEA), aminoethyl 50 parts of piperazine (AEP), 5 parts of methyl methacrylate, 10 parts of ethanol, 0.8 parts of azobis(2-amidinopropane) dihydrochloride, and 10 parts of hydrochloric acid.

[0036] A kind of preparation method of hydrophilic type color fixing agent for cotton fiber fabric, adopts following steps:

[0037] A. Take the raw materials according to the above ratio for subsequent use, and purify the vinylpyridine compound;

[0038] B. Mix the amine compound, acrylic compound, and solvent evenly at room temperature, heat to 25°C and keep it for 30 minutes, add vinylpyridine compound, mix well, continue to heat up to 50°C, keep the temperature for 30 minutes, and start to drop slowly to trigger agent, the initiator dropping time is 2.0h, the temperature rises to 80°C, ...

Embodiment 2

[0042] A hydrophilic color fixing agent for cotton fiber fabrics, which is polymerized by the following components by mass: 10 parts of 2-vinylpyridine (2VP), 20 parts of hydroxyethylethylenediamine (AEEA), aminoethyl 30 parts of piperazine (AEP), 20 parts of tetraethylenepentamine (TEPA), 5 parts of methyl methacrylate, 10 parts of dimethyl sulfoxide, 1.0 part of ammonium persulfate and 10 parts of hydrochloric acid.

[0043] A kind of preparation method of hydrophilic type color fixing agent for cotton fiber fabric, adopts following steps:

[0044] A. Take the raw materials according to the above ratio for subsequent use, and purify the vinylpyridine compound;

[0045] B. Mix the amine compound, acrylic compound and solvent evenly at room temperature, heat to 40°C and keep it for 30 minutes, add the vinylpyridine compound, mix it evenly, continue to heat up to 75°C, keep the temperature for 60 minutes, start to slowly drop the trigger agent; the dripping time of the initiat...

Embodiment 3

[0049] A hydrophilic color fixing agent for cotton fiber fabrics, which is polymerized from the following components by mass: 5 parts of 2-vinylpyridine (2VP), 5 parts of 4-vinylpyridine (4VP), aminoethyl 50 parts of piperazine (AEP), 20 parts of tetraethylenepentamine (TEPA), 5 parts of methyl methacrylate, 5 parts of ethanol, 5 parts of dimethyl sulfoxide, 1.0 part of ammonium persulfate and 10 parts of hydrochloric acid.

[0050] A kind of preparation method of hydrophilic type color fixing agent for cotton fiber fabric, adopts following steps:

[0051] A. Take the raw materials according to the above ratio for subsequent use, and purify the vinylpyridine compound;

[0052] B. Mix the amine compound, acrylic compound, and solvent evenly at room temperature, heat to 30°C and keep it for 30 minutes, add the vinylpyridine compound, mix it evenly, continue to heat up to 50°C, keep the temperature for 60 minutes, and start to slowly drop the trigger agent; the dripping time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com