Furnace pressure control system and control method for automobile steel production by using open-flame continuous annealing furnace

A furnace pressure control and continuous furnace withdrawal technology, applied in the field of metallurgical furnaces, can solve the problems of pressure fluctuation in the furnace and reduce the duration of negative pressure in the furnace, so as to achieve stable furnace pressure, reduce furnace pressure, and reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

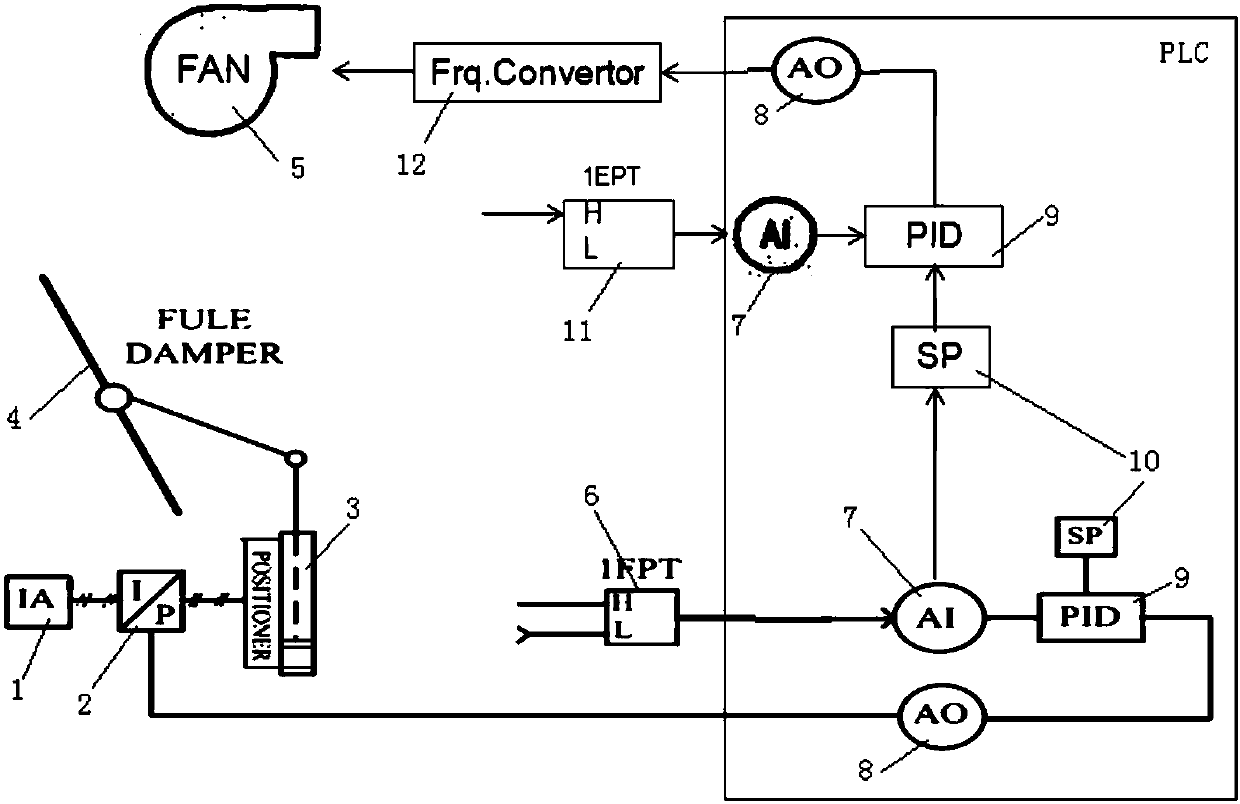

[0023] Such as figure 1 As shown, a furnace pressure control system for automobile steel production in an open flame continuous annealing furnace according to the present invention includes a pneumatic controller 2, a pneumatic valve positioner 3, a smoke gate 4, a furnace pressure sensor 6, and a smoke exhaust suction The sensor 11, the frequency converter 12, the frequency conversion fan 5 and the PLC system, the pneumatic controller 2 receives the pneumatic control air IA1 as the air source, and at the same time receives the output current of the analog output module AO8 of the PLC as the control quantity, which is given to the pneumatic valve positioner 3 The output pressure is used as the control gas, and the pneumatic valve positioner 3 is connected to the flue gas ram 4 to control the opening and closing of the flue gas ram 4, so as to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com