Continuous decomposition crystallization device for thermally decomposing carnallite to prepare potassium chloride

A crystallizer and carnallite technology, applied in solution crystallization, alkali metal chloride, alkali metal halide purification, etc., can solve the problems of small evaporation, large water consumption, complex process flow, etc., and achieve low consumption of manufacturing materials. , Increase the output and particle size, and enhance the effect of material circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

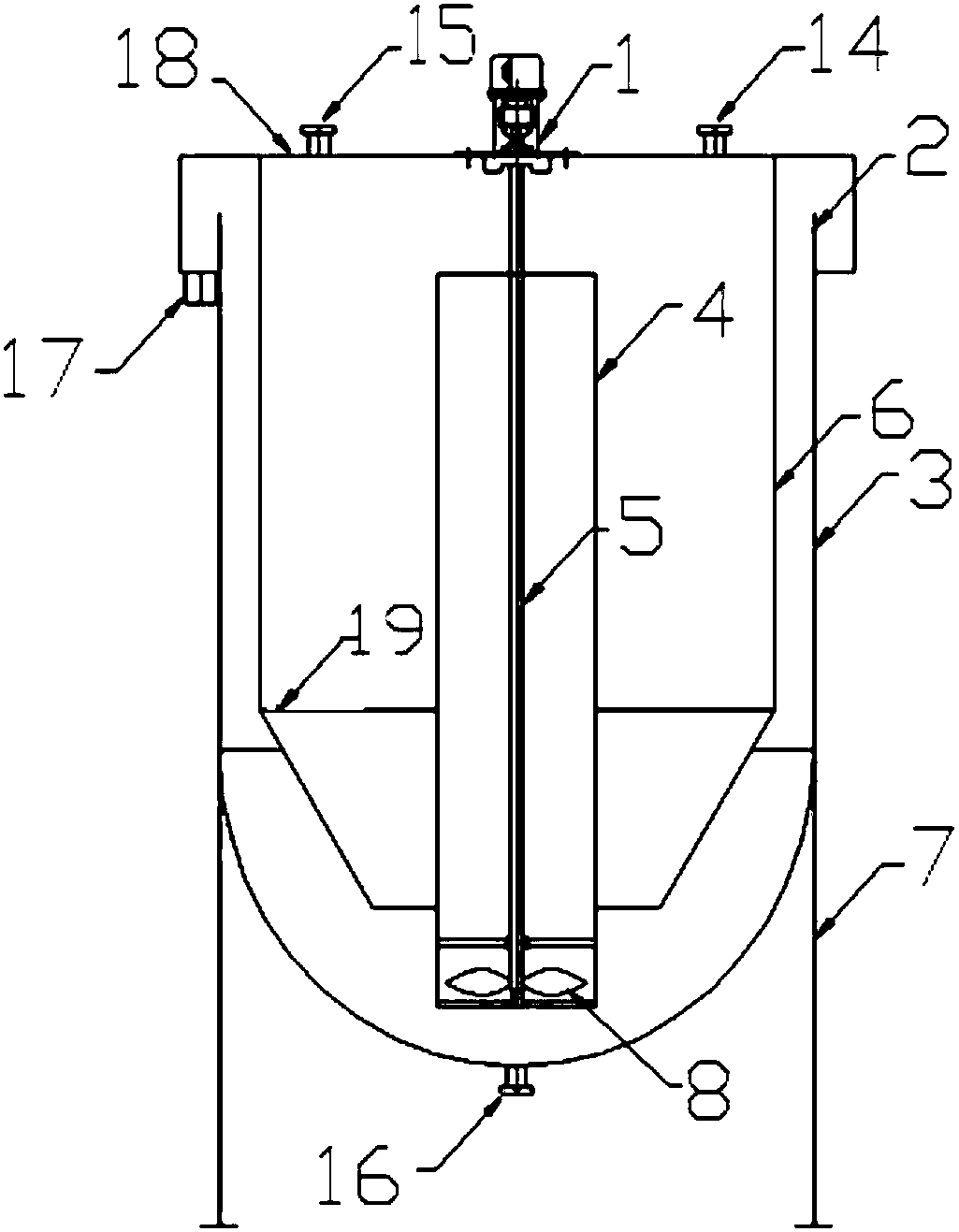

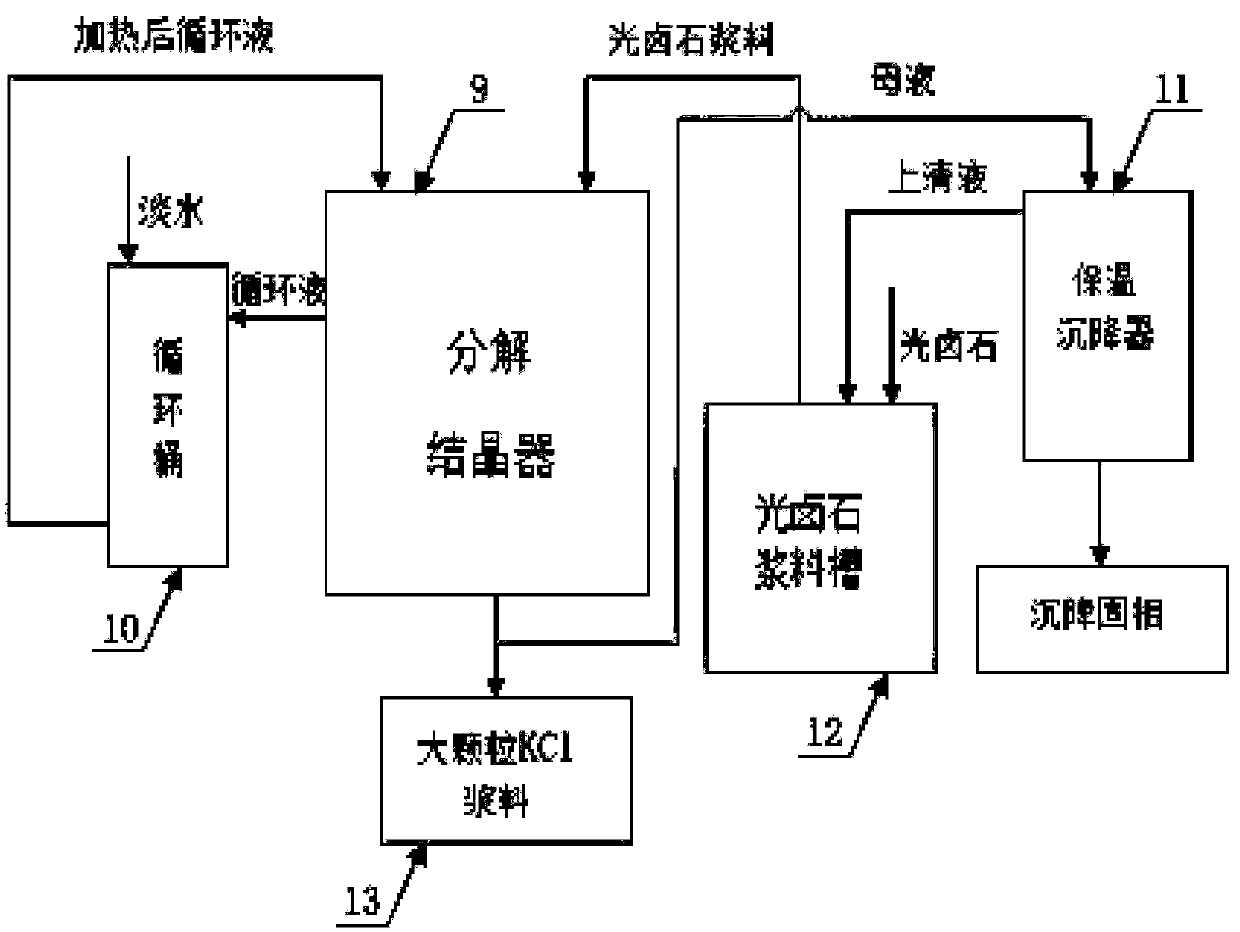

[0022] Such as figure 1 As shown, a continuous decomposition crystallizer 9 for producing potassium chloride by thermal decomposition of carnallite is mainly composed of a cylinder body 3 and a cover body 18. Accumulation of particles occurs, and the particles with high density can be discharged faster. The cylinder body 3 is provided with a stirring shaft 5 with a guide tube 4. In order to absorb smaller particles of potassium chloride, it is forced to accelerate the material circulation and Away from the overflow area, the stirring paddle 8 on the stirring shaft 5 is close to the bottom of the cylinder body 3, and the cover body 18 is provided with a carnallite feed port 14 and a circulating liquid feed port 15, such as figure 2 As shown, the carnallite feed port 14 and the circulating liquid feed port 15 are respectively located on both sides of the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com