Material-saving optimized type cement pile machine

A cement pile, material-saving technology, applied in the direction of sheet pile walls, drilling equipment and methods, construction, etc., can solve the problems of reducing the bearing capacity of ground piles, multiple raw materials, waste, etc., to reduce project cost and promote full refinement , The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

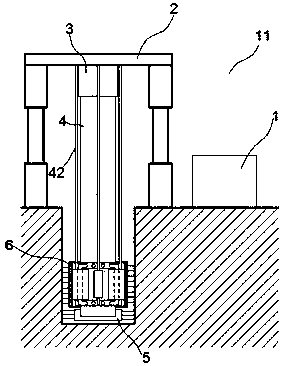

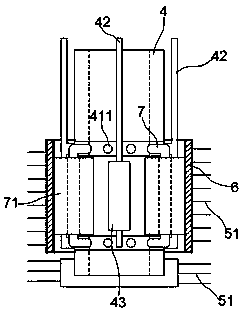

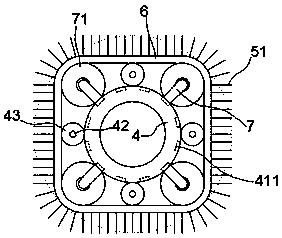

[0019] exist Figure 1 to Figure 3 In the shown embodiment, this material-saving optimized cement pile driver includes a grouting machine 1, a support frame 2, a driving machine 3, a transmission rod 4 and a drill bit 5; the upper end of the transmission rod 4 is detachably installed on the driving machine 3 Above, the drill bit 5 is arranged at the lower end of the transmission rod 4; a grouting port is opened on the drill bit 5; a cutting blade 51 is also arranged on the drill bit 5;

[0020] The transmission rod 4 is a hollow structure, and a guide pipe 11 is interspersed in the hollow area of the transmission rod 4, and one end of the guide pipe 11 is connected with the grouting machine 1, and the other end is communicated with the grouting port on the drill bit 5; The grouting port is equidistantly arranged on the bottom and the side peripheral wall of the drill bit 5, and the spraying direction of the grouting port is parallel to the plane where the adjacent excavation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com