Portable seawater microplastic sampling and pretreating device and method

A microplastic and portable technology, applied in the field of marine environmental monitoring, can solve the problems of real-time observation of microplastics in unsuitable seawater, cumbersome steps, and easy contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

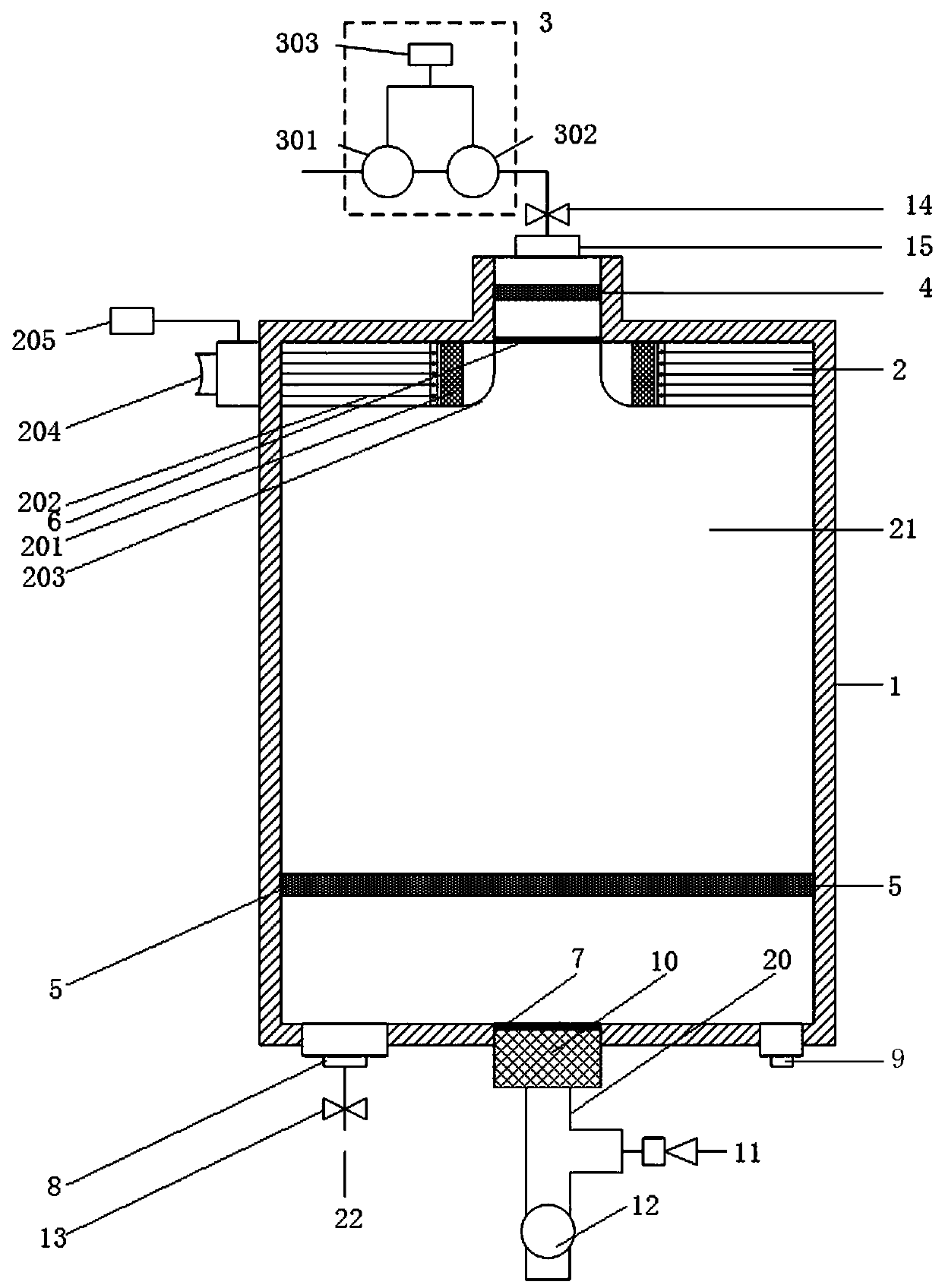

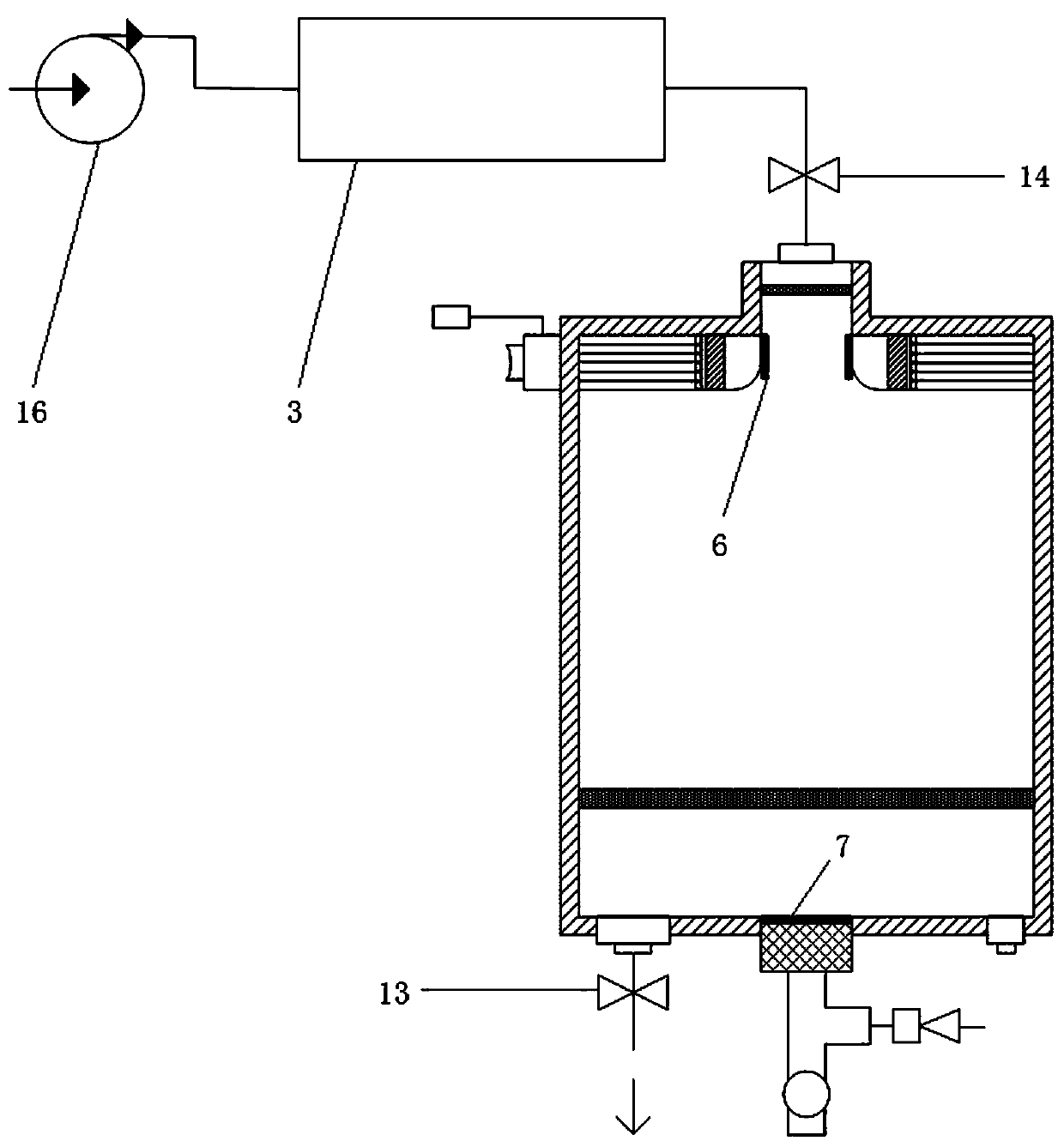

[0030] A portable seawater microplastic sampling and pre-processing device includes a housing 1, a water inlet 15 arranged at the upper end of the housing 1, a first screen 4, a second screen 5, a water outlet 8 arranged at the lower end of the housing 1, and a spray The head 10, the exhaust port 9, the electrothermal ultrasonic generating device 2 arranged in the housing 1 and connected to the water inlet 15, a pressure and flow control device 3 arranged outside the housing 1 and connected to the water inlet 15.

Embodiment 2

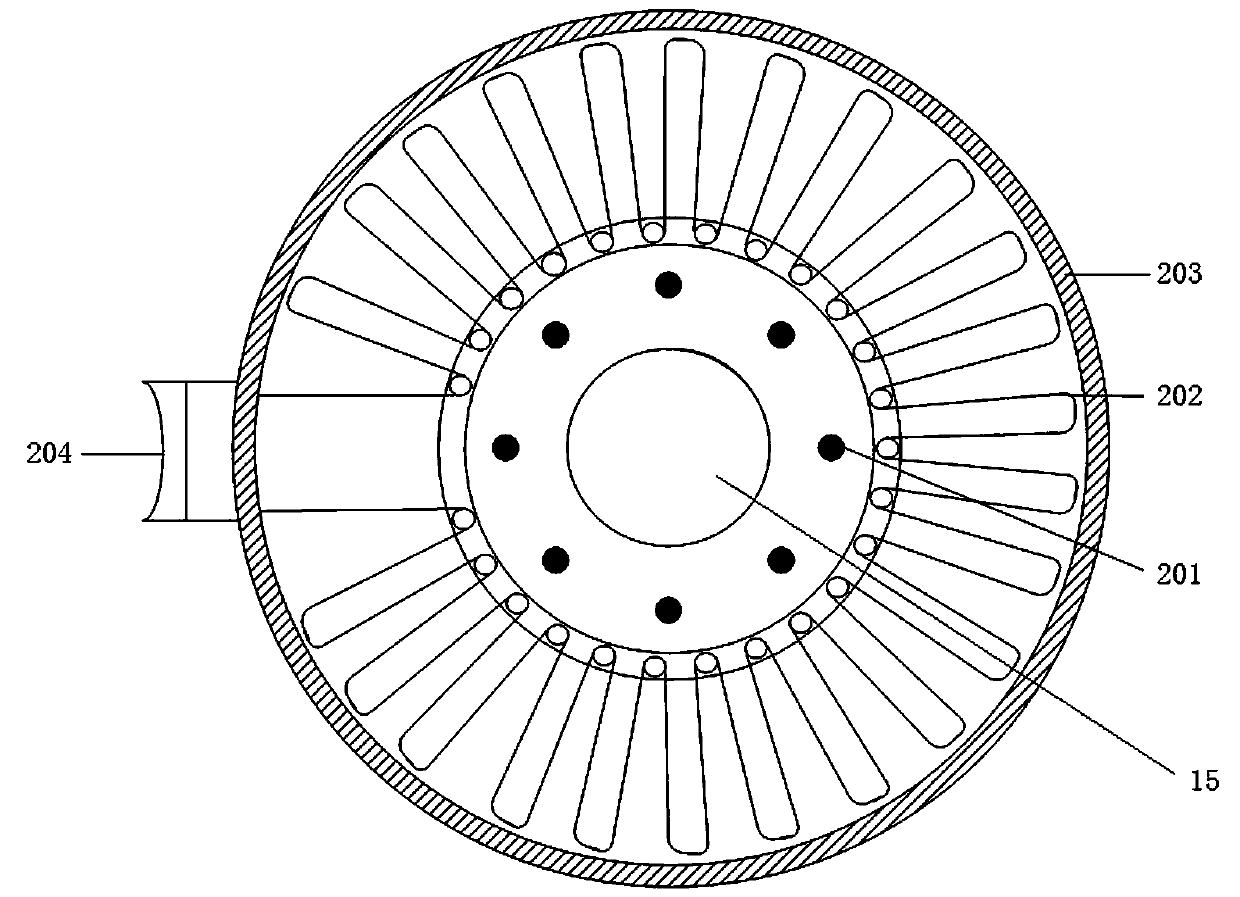

[0032] Compared with Embodiment 1, the electrothermal ultrasonic generating device 2 includes an inner shell 203, a second power source 205, an ultrasonic vibrator 201, a heating wire 202 and a switch 204. The heating wire 202 has a ring shape, and the ultrasonic vibrator 201 is located inside the ring structure formed by the heating wire. The electrothermal ultrasonic generating device 2 is a thermostatic heating ultrasonic device with a constant temperature of 60°C.

Embodiment 3

[0034] Compared with Embodiment 1, the pressure and flow control device 3 includes a first power source 303, a flow controller 301, and a pressure alarm 302. The water inlet 15 in the housing 1 is provided with a first switch sheet 6 and the shower head 10 is provided with a second switch sheet 7. The first switch sheet 6 and the second switch sheet 7 are made of polytetrafluoroethylene. The first screen 4 is a stainless steel material, and the second screen 5 is a polytetrafluoroethylene material. The pressure and flow control device 3 is connected to the water pump 16. A first valve 14 is provided at the water inlet 15 and a second valve 13 is provided at the water outlet 8. The spray head 10, the syringe 11 and the pressure pump 12 are connected by a three-way valve 20 . The water inlet 15 has a threaded structure and can be threadedly connected with the pressure and flow control device 3 or the water pump 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com