Cyclone gas atomization type powder making device using liquid metals

A technology of liquid metal and pulverizing device is applied in the field of metal pulverizing, which can solve the problems of low roundness and different sizes of particles, and achieve the effects of avoiding excessive temperature, improving roundness and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

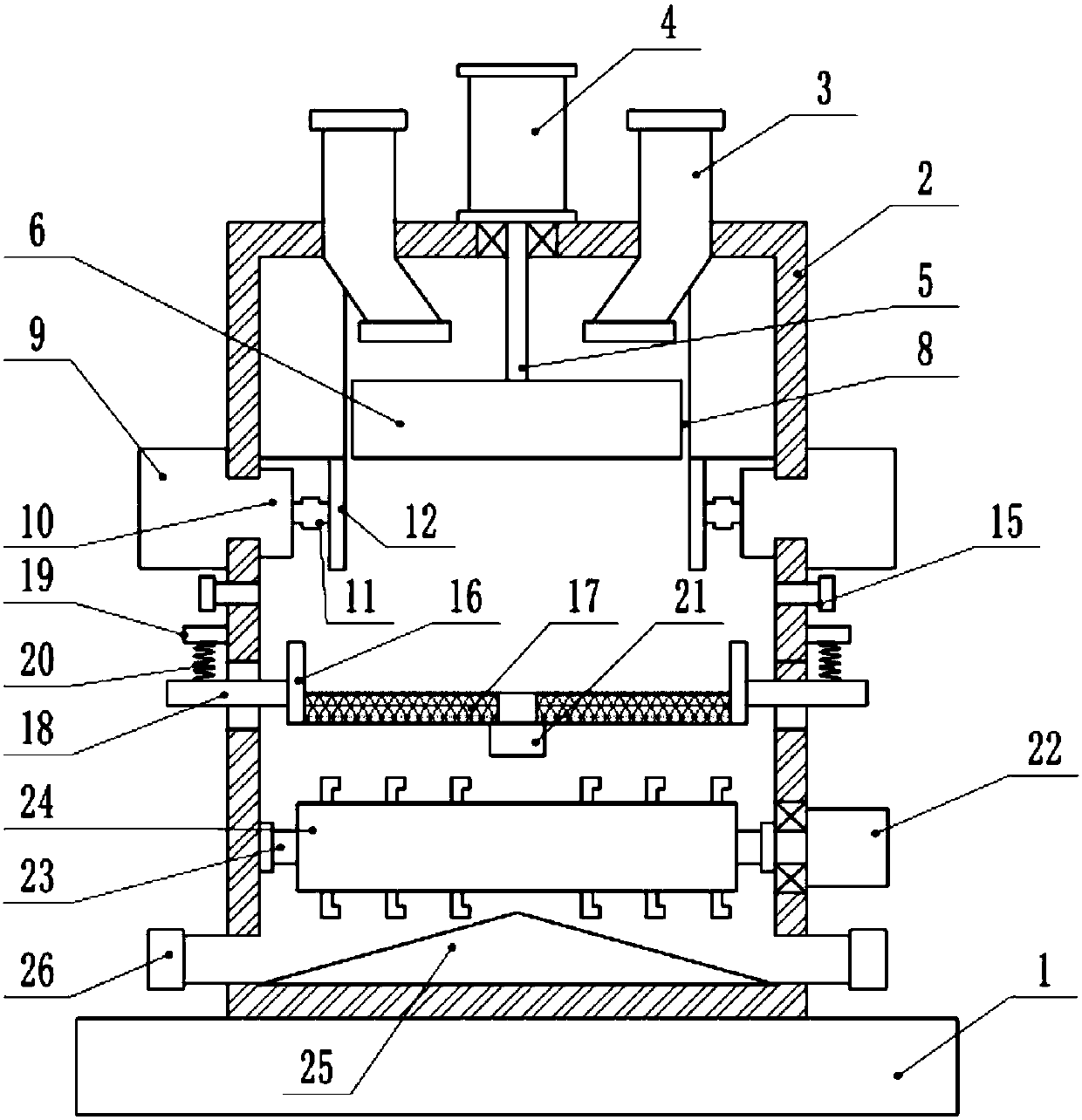

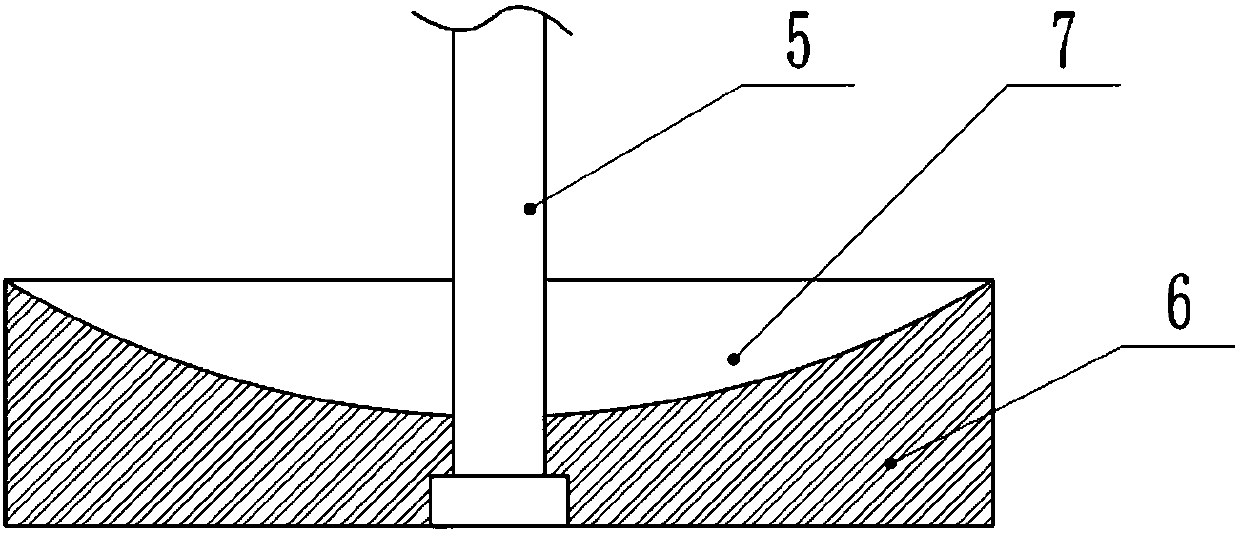

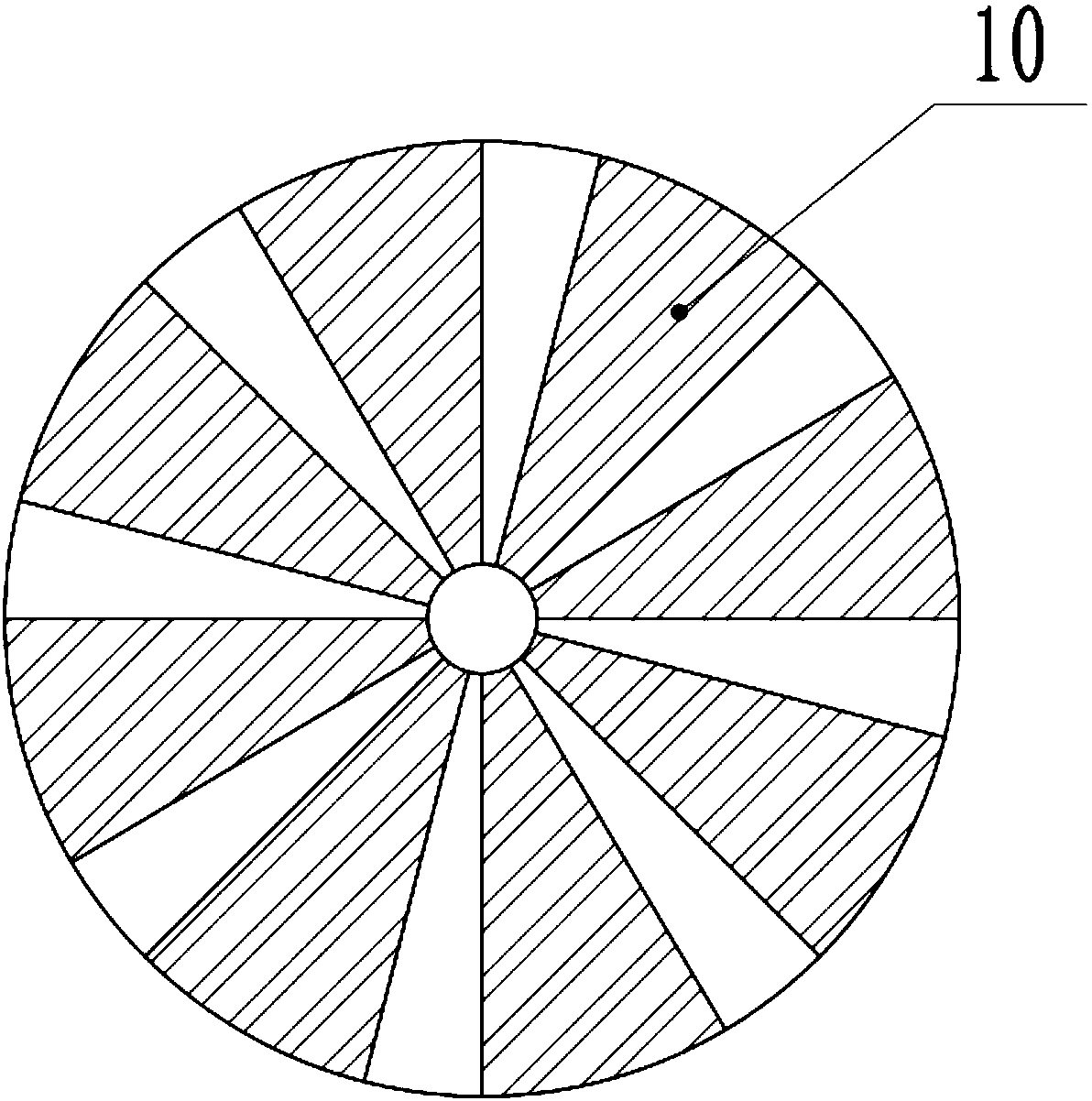

[0022] See Figure 1-4 , A liquid metal cyclone gas atomization type powder making device, including powder making box 2, ultra-high-speed motor 4, centrifugal turntable 6, barrel 8, high-speed motor 9, cyclone turntable 10, spray rod 12, screening box 16, vibration The motor 21 and the stirring roller 24, the base 1 is provided with a powder making box 2, and the base 1 and the powder making box 2 are fixedly connected by screws. The upper side of the powder making box 2 has two sets of feed inlets symmetrically opened. 3. A feed pipe is installed on the feed port 3, the feed pipe is made of high temperature resistant alloy material, the feed pipe extends into the powder making box 2, and the upper center of the powder making box 2 is fixedly installed with a super The output shaft of the high-speed motor 4 and the ultra-high-speed motor 4 extends d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com