Continuous production method of PI film heater and production equipment of PI film heater

A film heater and heating pressure technology, applied in ohmic resistance heating, electric heating devices, electrical components, etc., can solve problems such as easy generation of air bubbles, lower product qualification rate, and a large number of manual operations, so as to achieve continuous mass production and improve product quality. Yield rate and effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

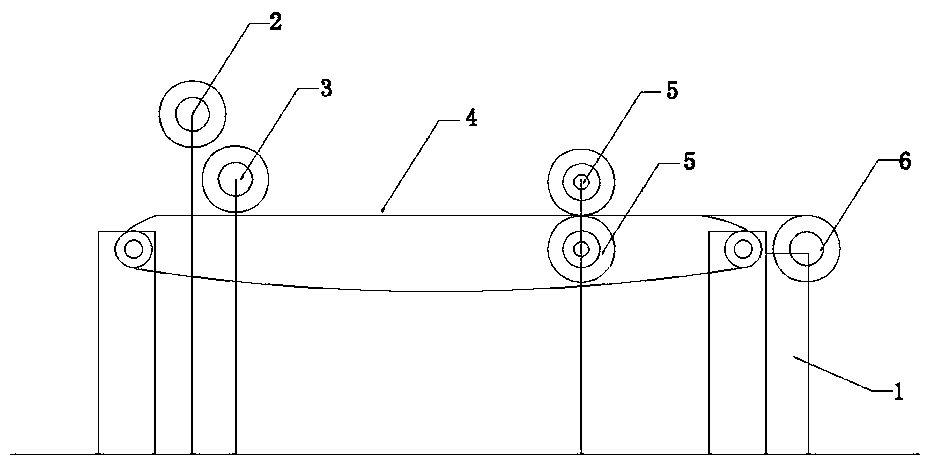

[0018] Such as figure 1 Shown, laminating machine, it comprises frame 1, the first discharge roller 2, the second discharge roller 3, conveyer belt 4, heating pressure roller 5 and first take-up roller 6; Conveyor belt 4 is horizontally arranged on machine On the frame 1, the first discharge roller 2 is arranged on the frame 1 above one end of the conveyor belt 4, the first winding roller 6 is arranged on the frame 1 of the other end of the conveyor belt 4, and the second discharge roller 3 Be arranged on the frame 1 below the rear side of the first discharge roller 2 above the conveyor belt 4, a pair of heated pressure rollers 5 are vertically arranged on the frame 1 in the middle of the conveyor belt 4, and the pair of heated pressure rollers 5 can The coils of the first discharge roller 2 and the second discharge roller 3 conveyed on the conveyor belt 4 are heated and pressed together.

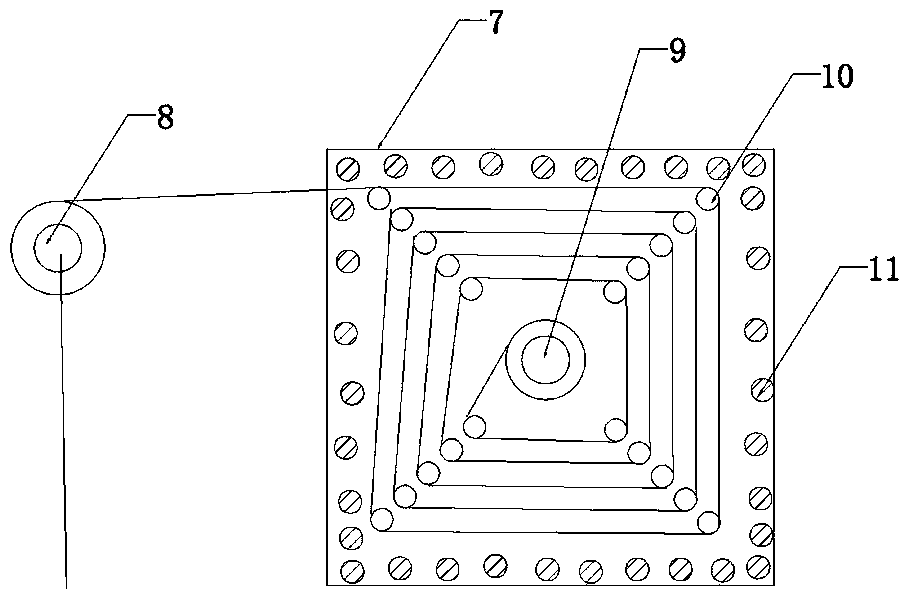

[0019] Such as figure 2 As shown, the continuous vulcanizer includes oven 7, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com