Patents

Literature

41results about How to "Reduce high production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

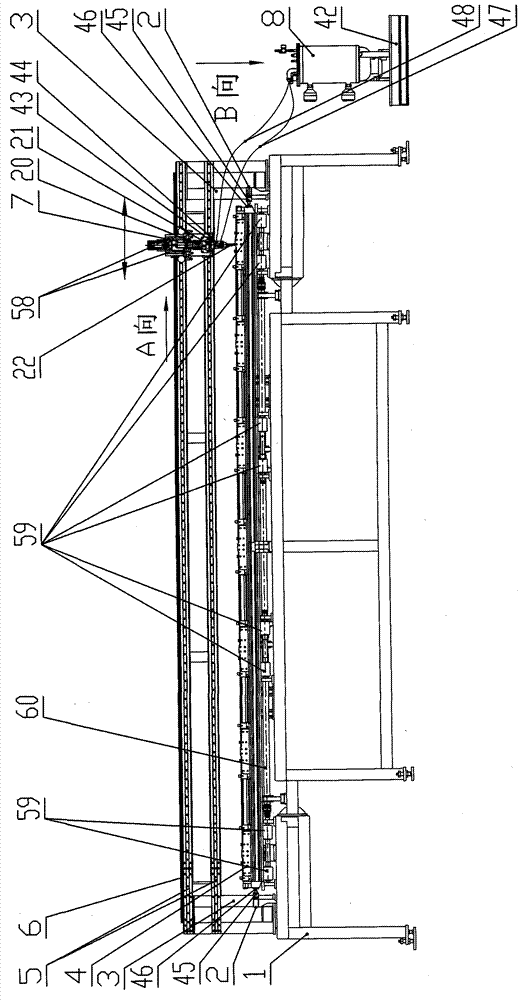

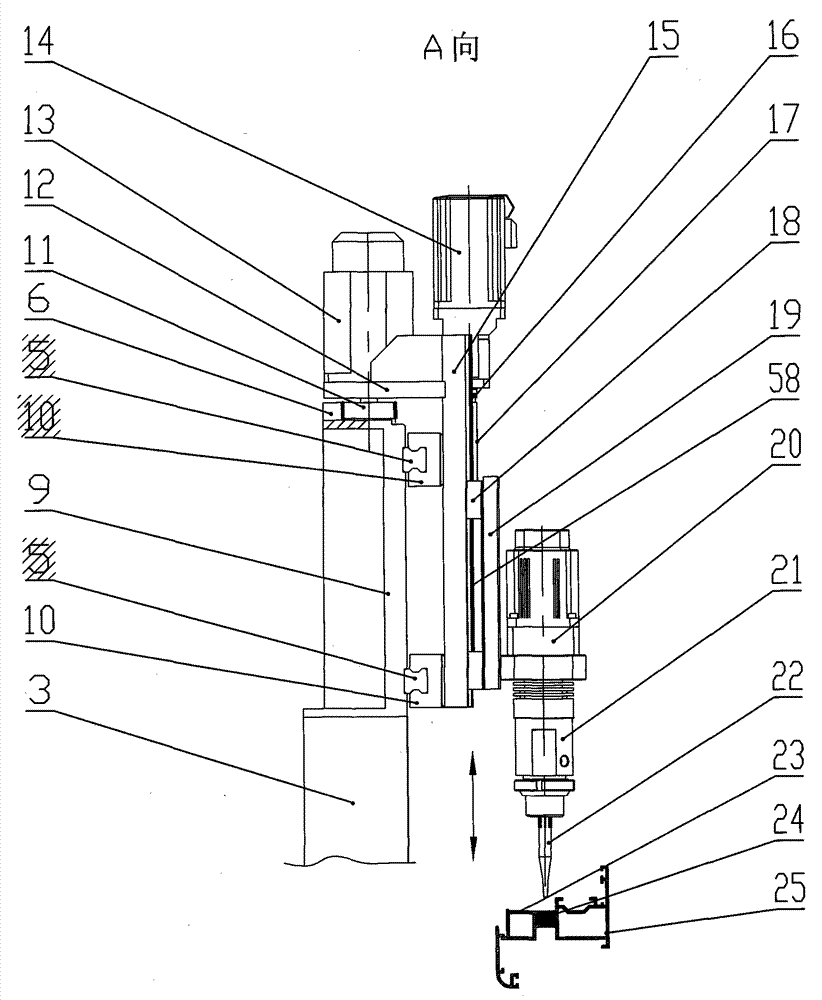

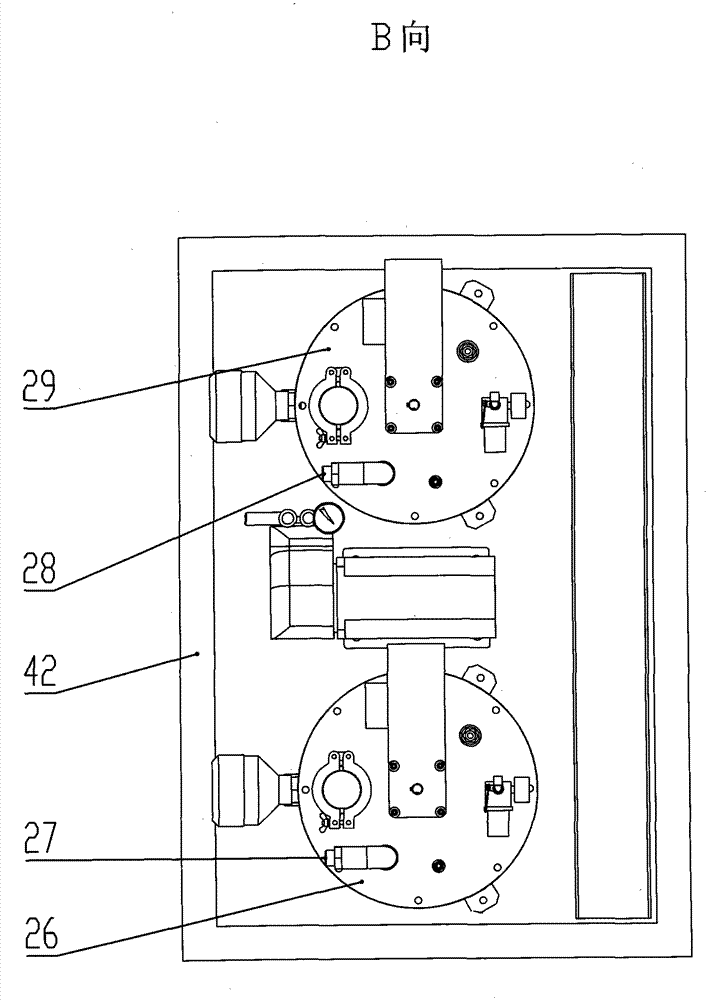

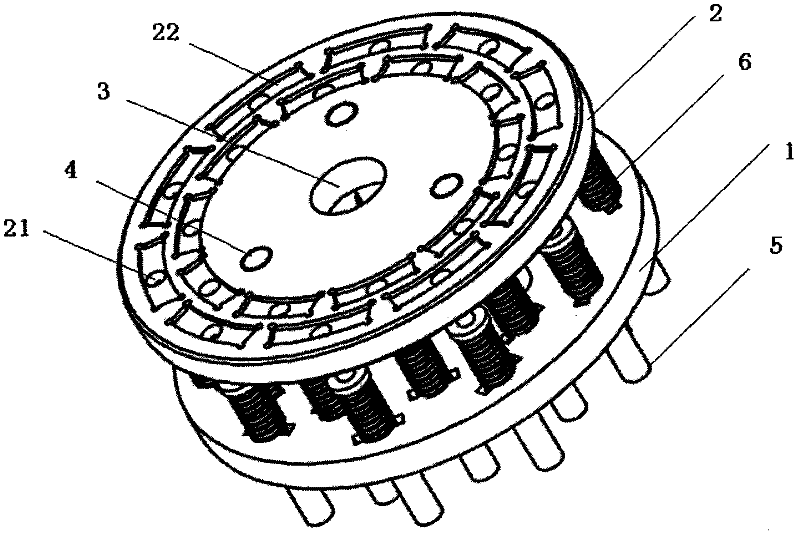

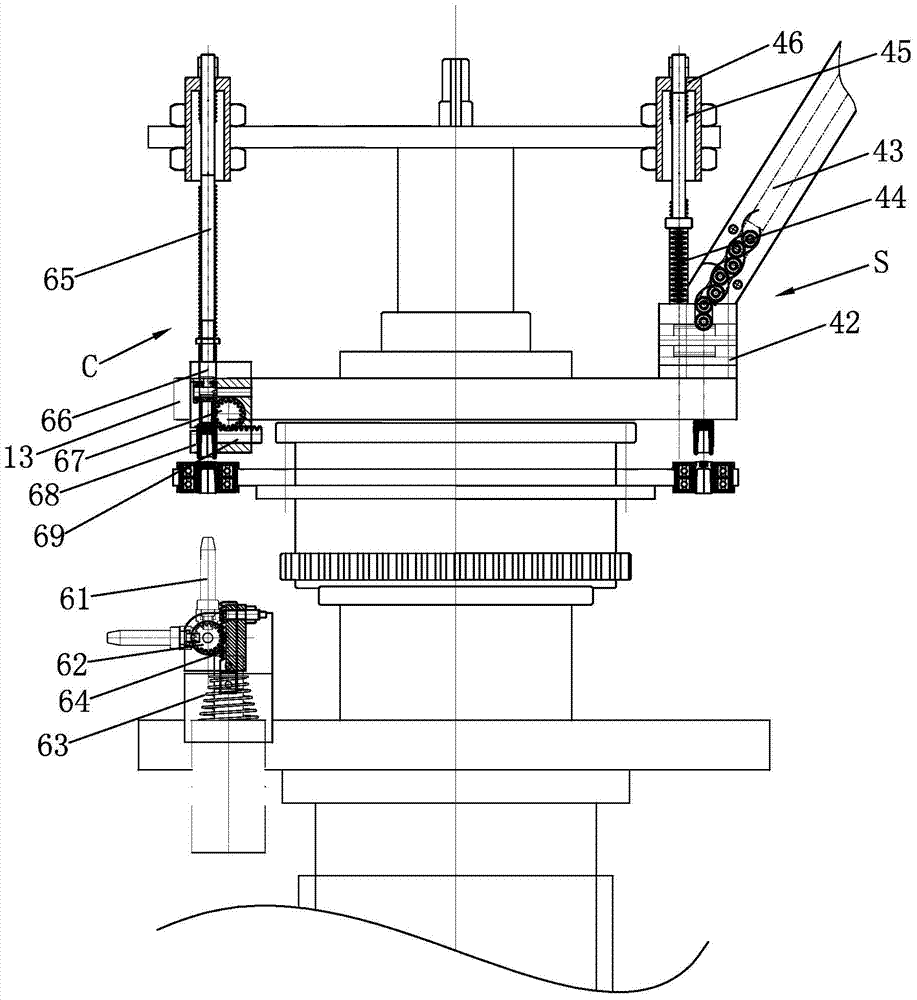

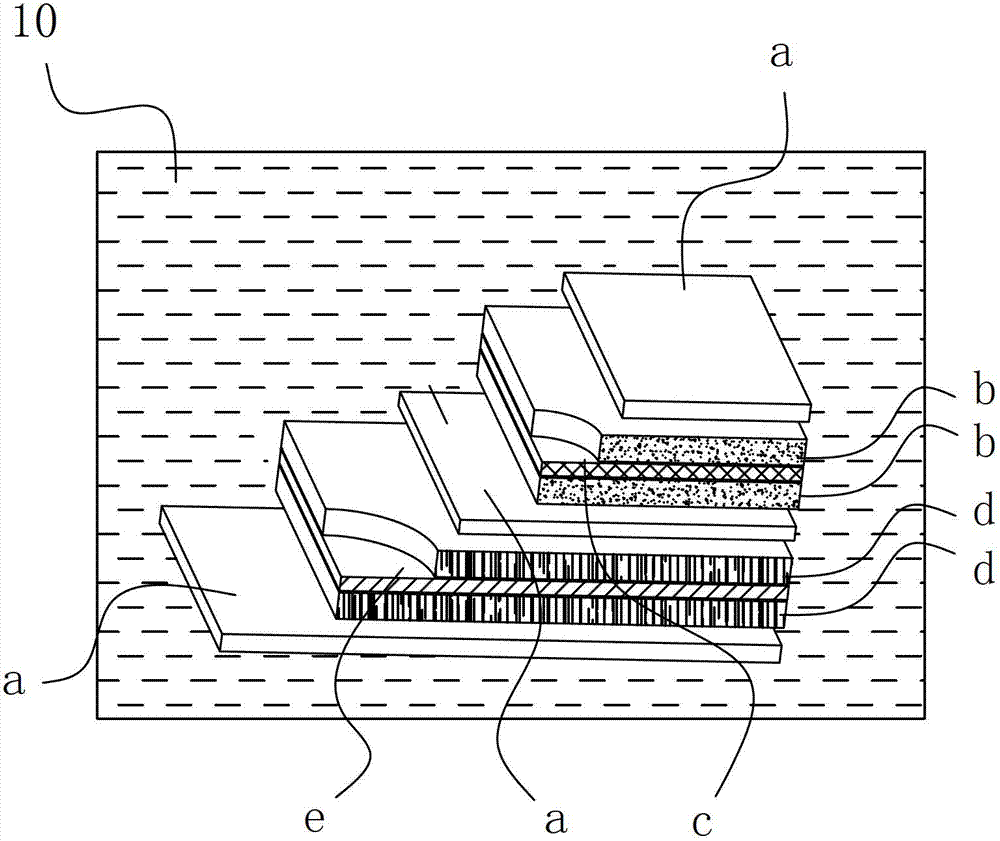

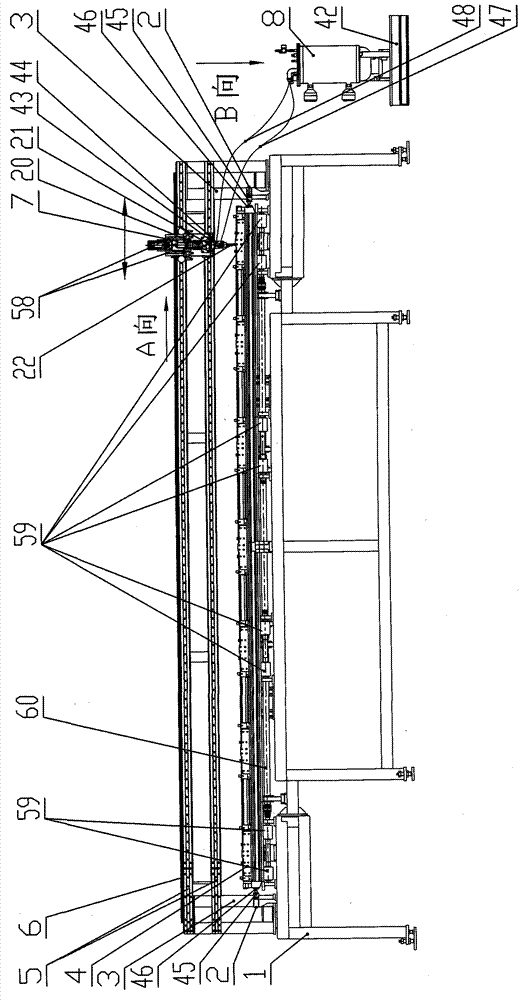

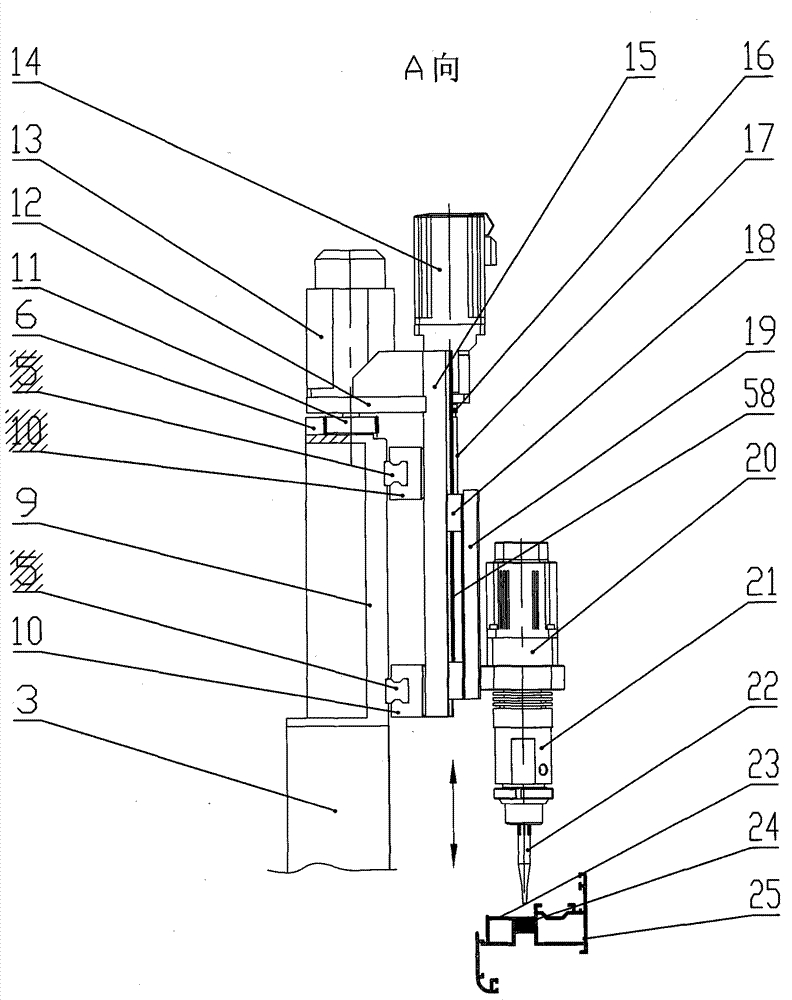

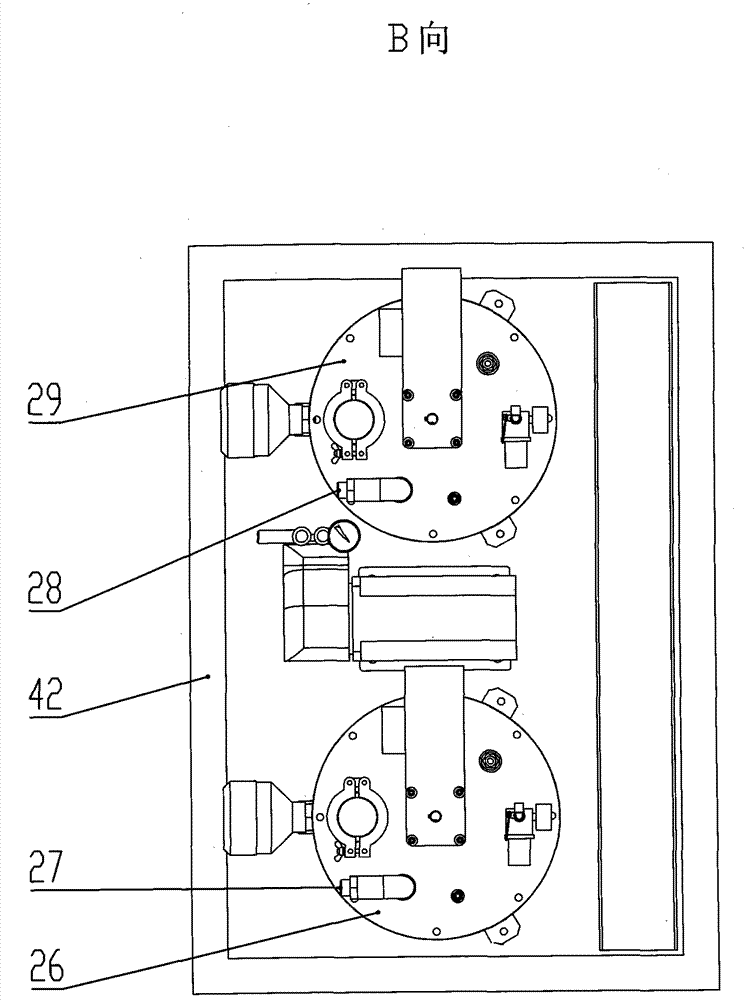

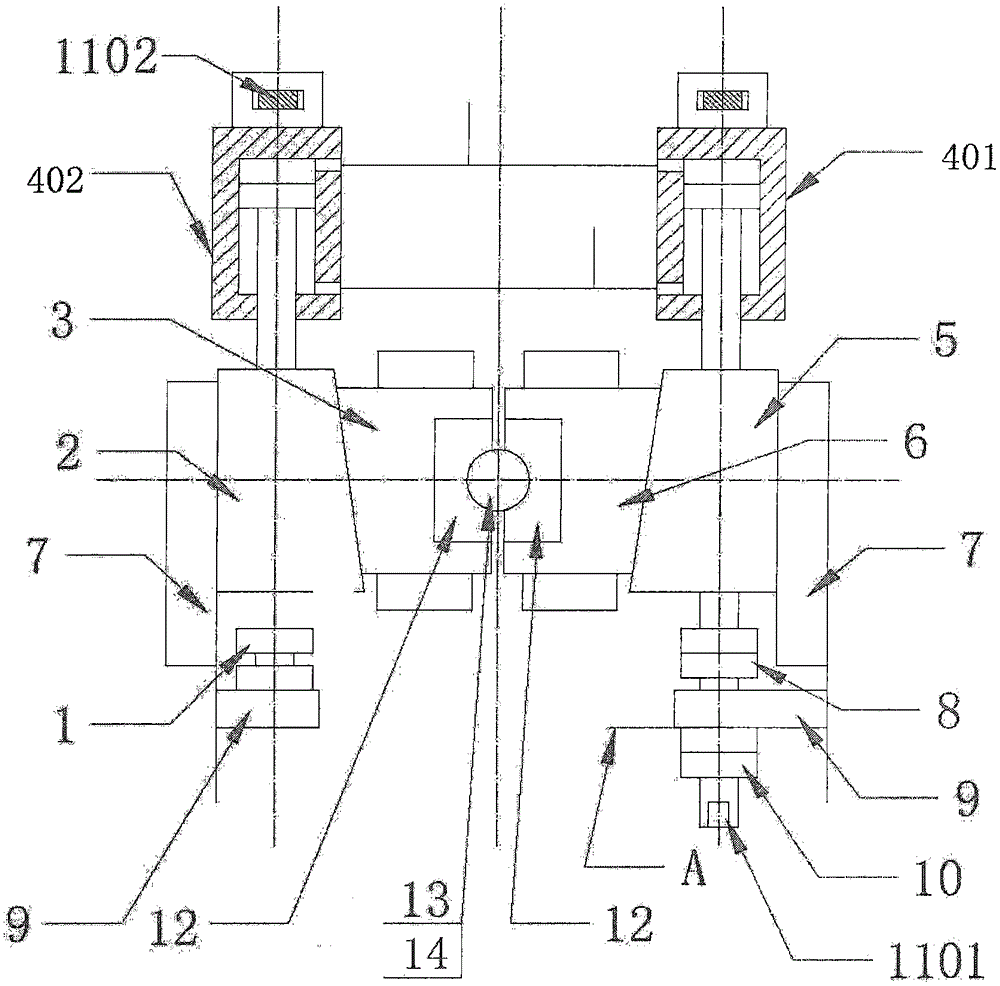

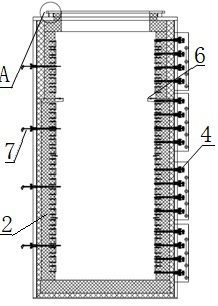

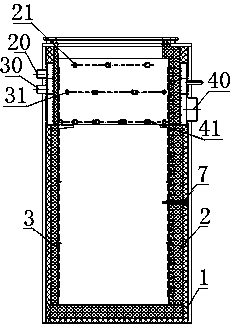

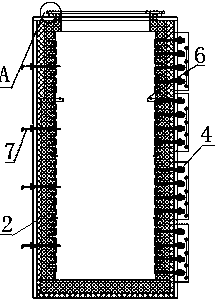

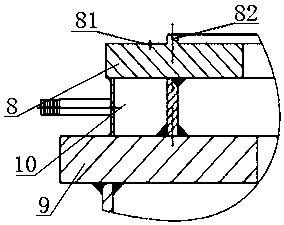

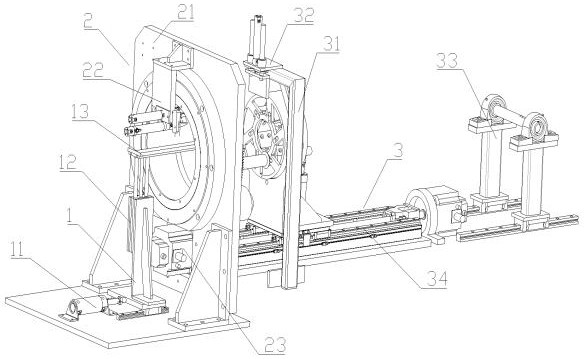

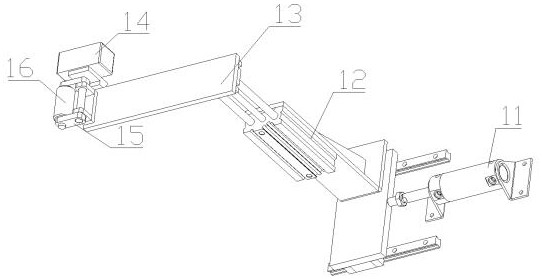

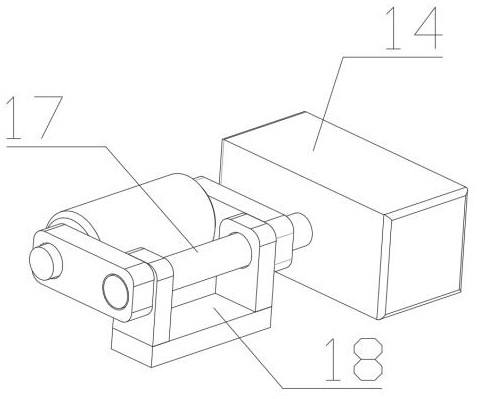

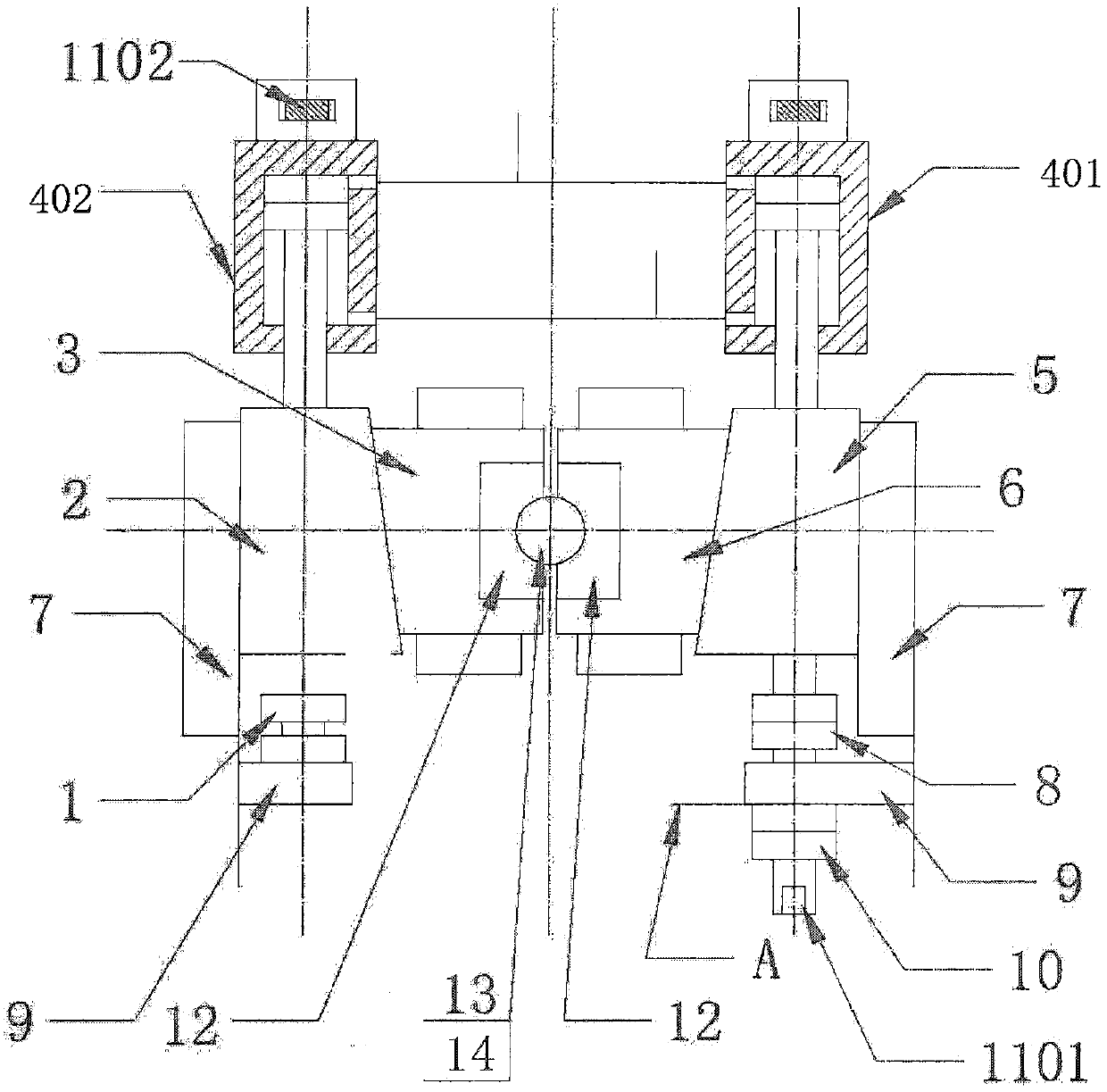

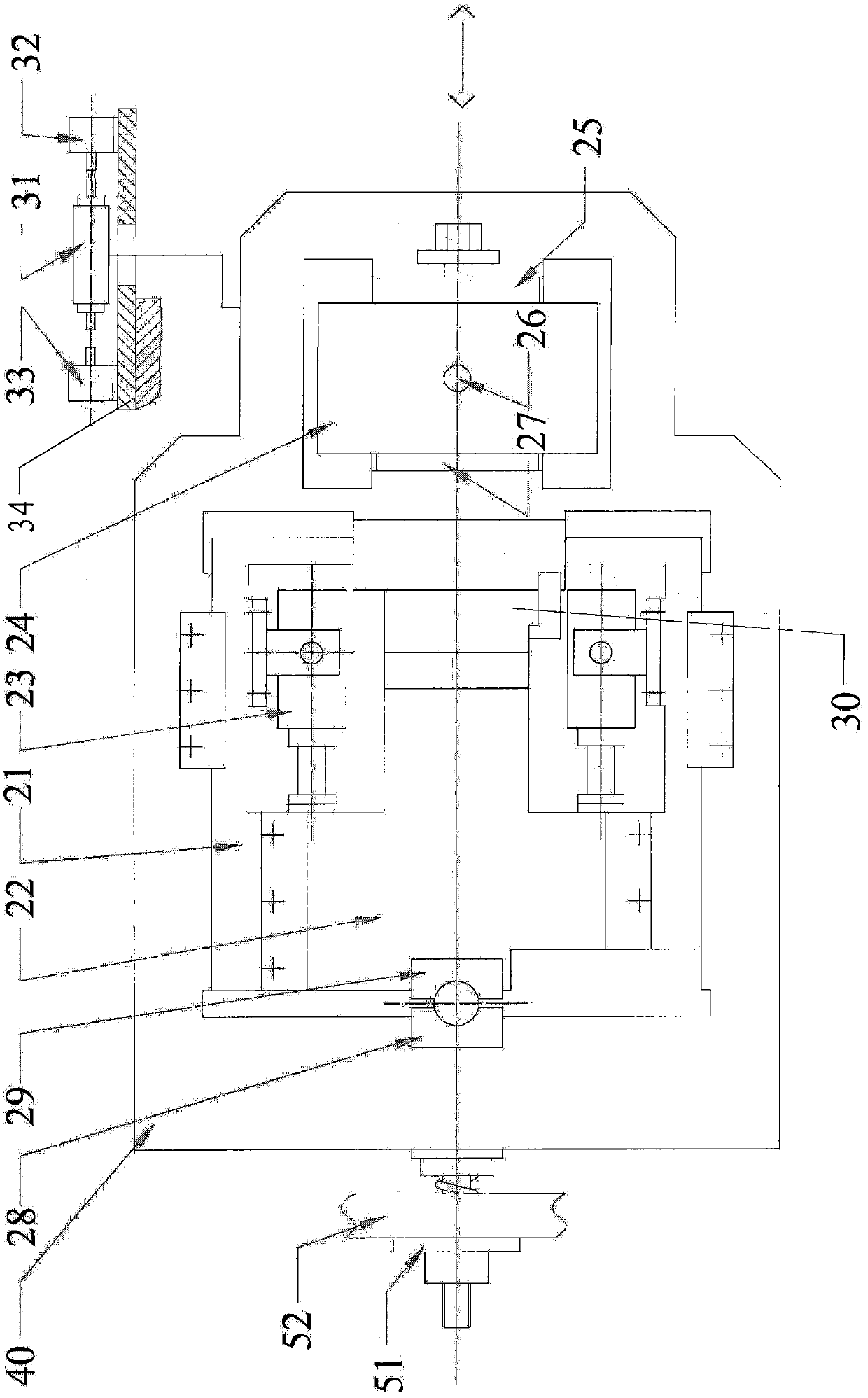

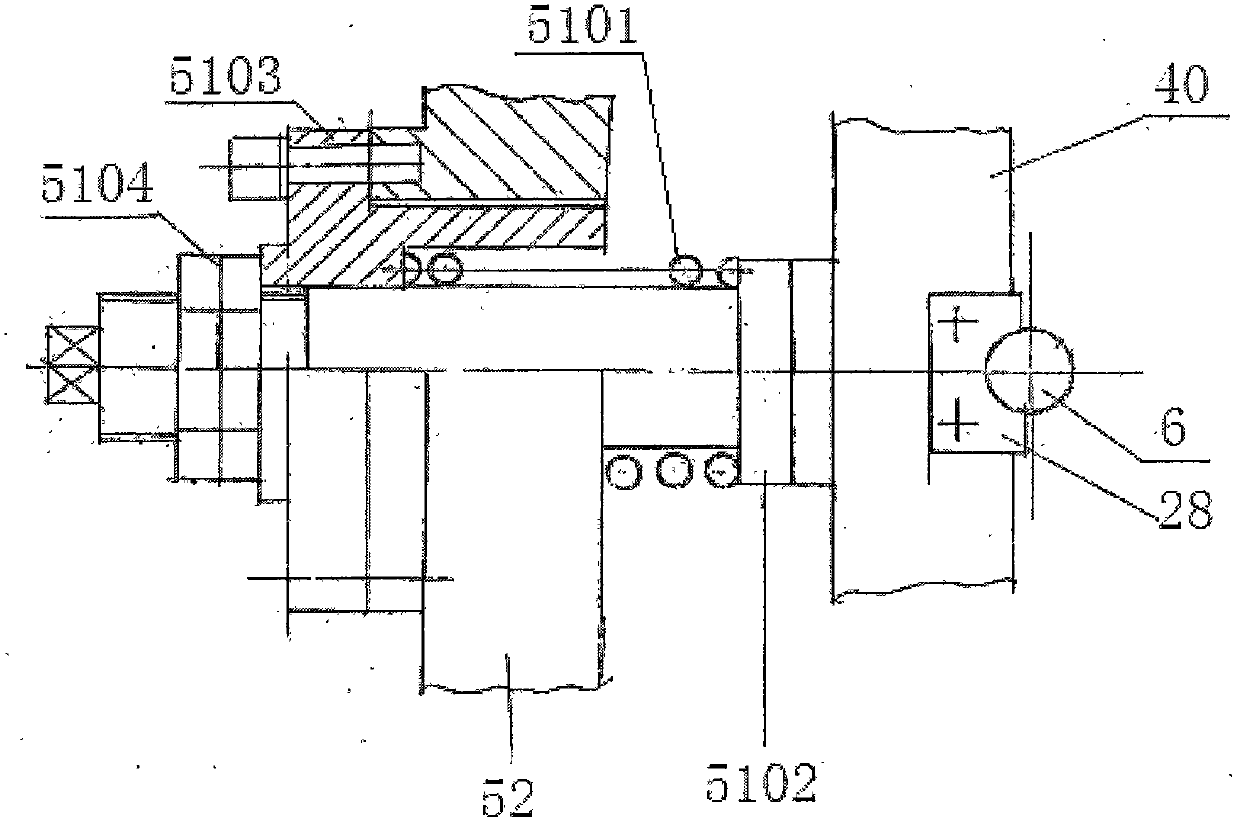

Molding device for bridge-cutting-free heat-insulation aluminum profiles

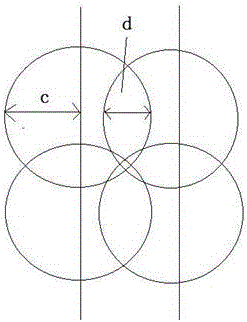

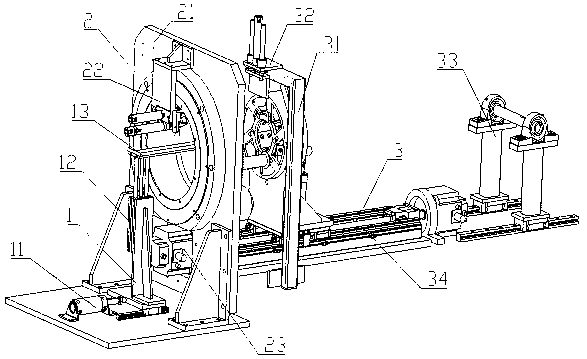

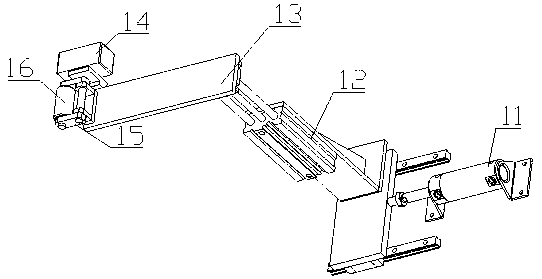

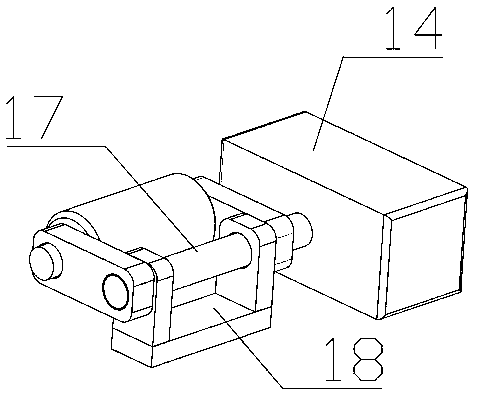

The invention provides a molding device for bridge-cutting-free heat-insulation aluminum profiles and relates to the fields of manufacturing of the heat-insulation aluminum profiles, machining of aluminum profile doors and windows and the like, aiming at overcoming the problems of an existing heat-insulation aluminum profile manufacturing process that time and labor are wasted, the energy source consumption is great, the manufacturing cost is high and the production efficiency is low since an aluminum alloy connection part needs to be cut off after the curing. The molding device is composed of a rack, a follow fixture, a glue supplying system and a glue injection head; one aluminum profile C with the complicated section is divided into two parts to manufacture two aluminum profiles A and B with the simple sections; then the aluminum profiles A and B are put into the follow fixture; the follow fixture and the glue injection head move relatively; a glue injection nozzle is used for mixing and agitating double-component polyurethane and then pouring the mixture into a pouring groove opening B formed by the aluminum profiles A and B; a polyurethane heat-insulation strip A is formed by curing and molding the double-component polyurethane and the aluminum profiles A and B are connected integrally to achieve connection and heat-insulation effects, so that a bridge cutting procedure can be omitted. With the adoption of the molding device and method provided by the invention, the single-color or double-color bridge-cutting-free heat-insulation aluminum profiles can be machined.

Owner:DALIAN HUAGONG INNOVATION TECH

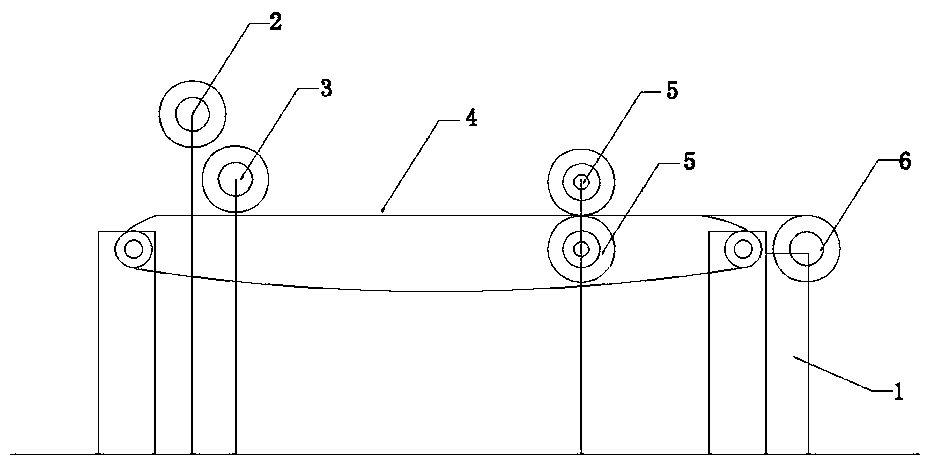

Integral high-frequency brazing process using welding fixtures

ActiveCN102294528ASimple structureEasy to useWelding/cutting media/materialsSoldering mediaAdjuvantFiller metal

The invention relates to a process for carrying out entire high-frequency brazing by a welding jig, which comprises the preparation of a matrix and the preparation of diamond gear blocks. Uniformly stirred silver based brazing filler metal and welding adjuvants are uniformly coated on surfaces to be brazed of the diamond gear blocks, then a millstone matrix and the diamond gear blocks are positioned and fixed by the welding jig, and finally the millstone matrix and the diamond gear blocks are arranged in a vacuum brazing furnace to be brazed. The process for carrying out entire high-frequencybrazing by the welding jig overcomes the technical problems of complex manufacturing process, low production efficiency, unstable quality and high production cost of the diamond millstone in the prior art, and on the premise of ensuring the welding quality to be stable, the brazing efficiency is greatly improved, and the production cost is effectively reduced.

Owner:江苏华昌工具制造有限公司

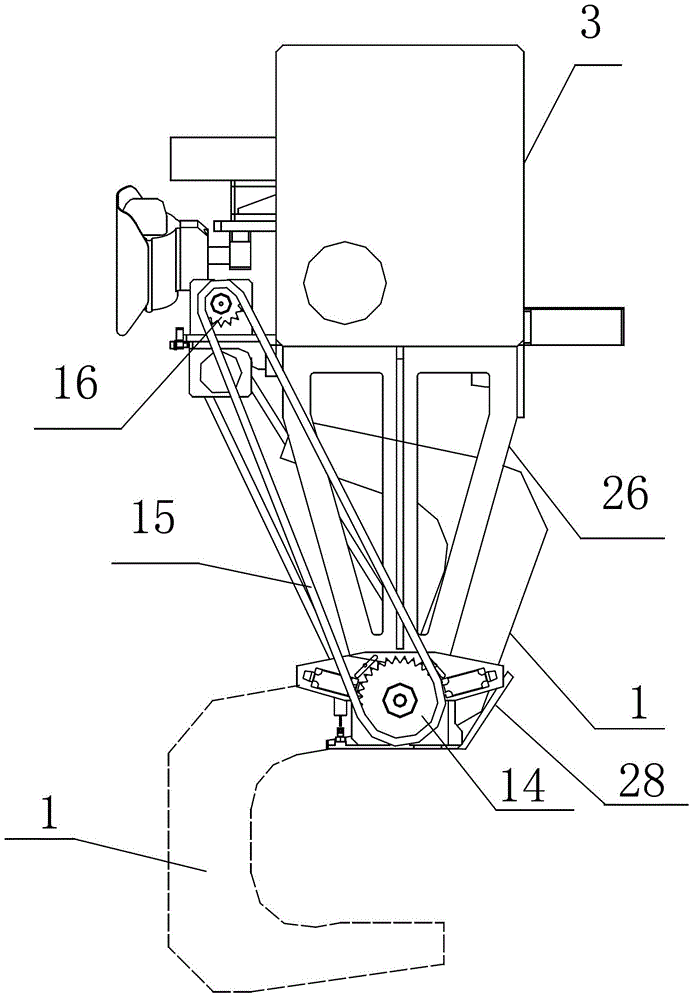

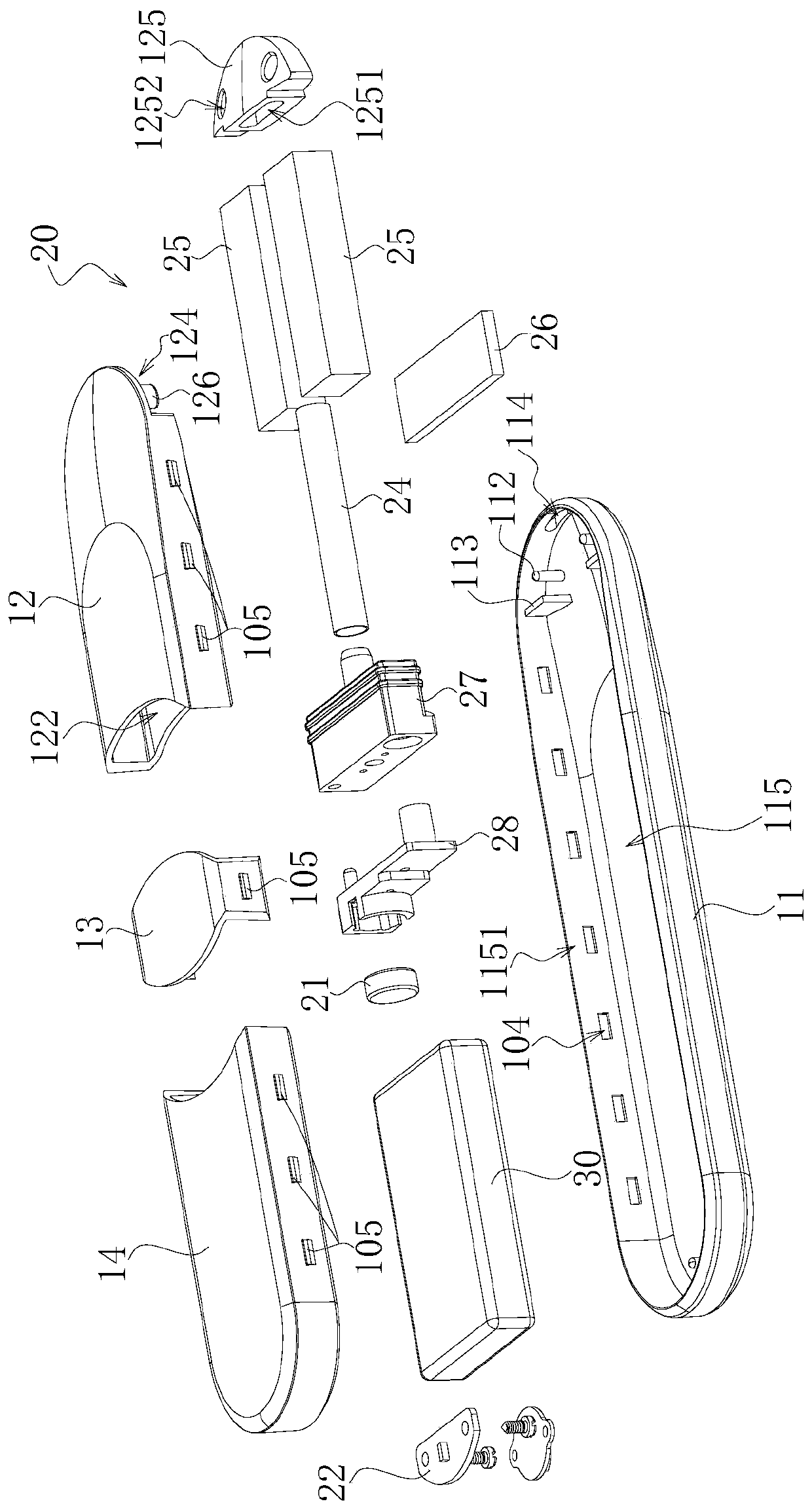

Automatic suspender

ActiveCN103332588AOvercoming inefficienciesImprove work efficiencyLoad-engaging elementsAutomotive engineeringWorkload

The invention discloses an automatic suspender. The suspender comprises a suspension arm and at least a suspension hook. The suspender is characterized in that at least one suspension hook is movably arranged on the suspension arm. The invention provides an automatic suspender. The suspender realizes automatic article lifting, overcomes the shortages of low efficiency, high production cost, large workload, high work strength, and high danger for a person in a handling zone, which are caused by human operation of a conventional suspender, improves work efficiency, and reduces production cost and work strength of workers.

Owner:上海朗卫自动化科技有限公司

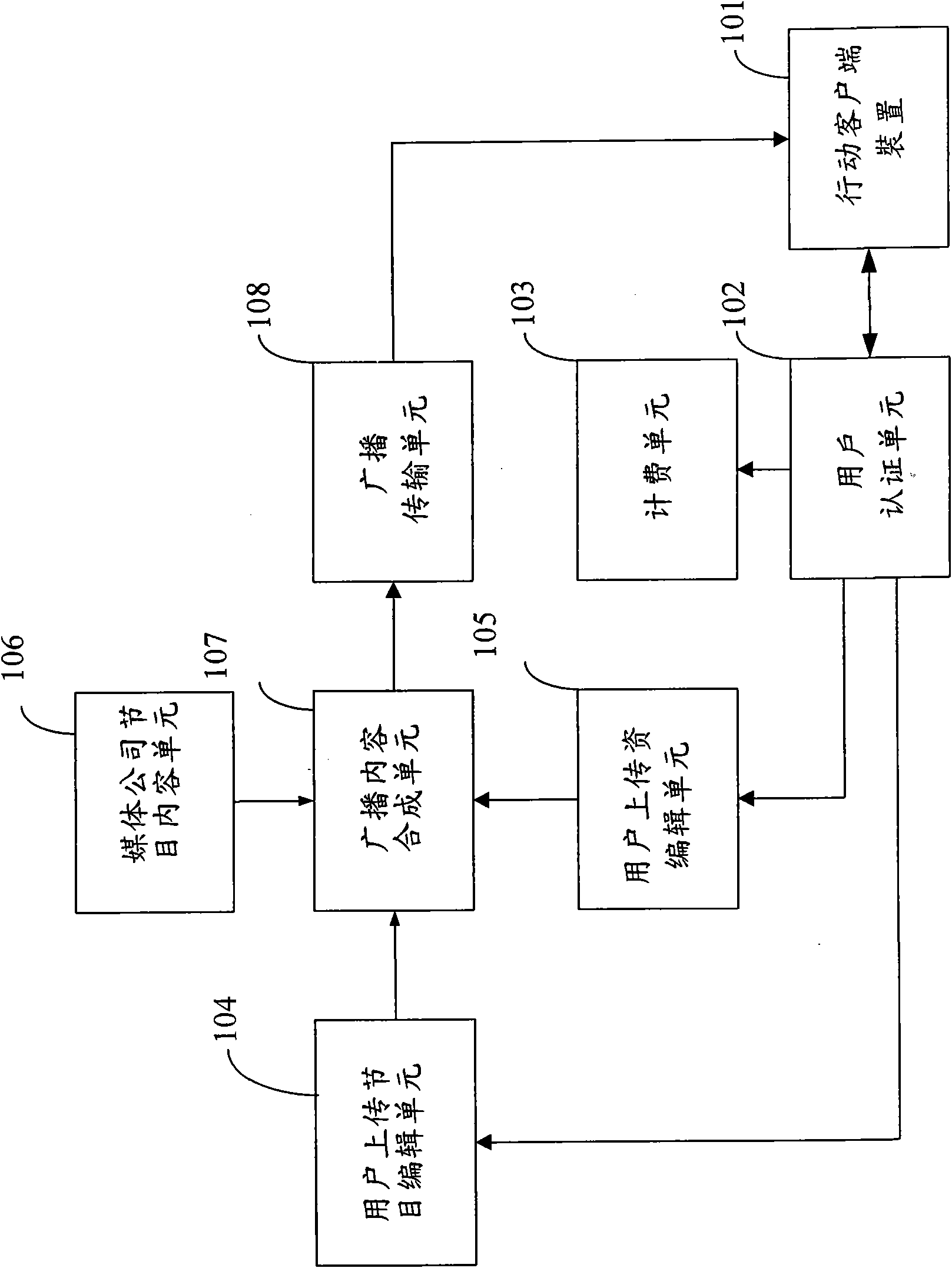

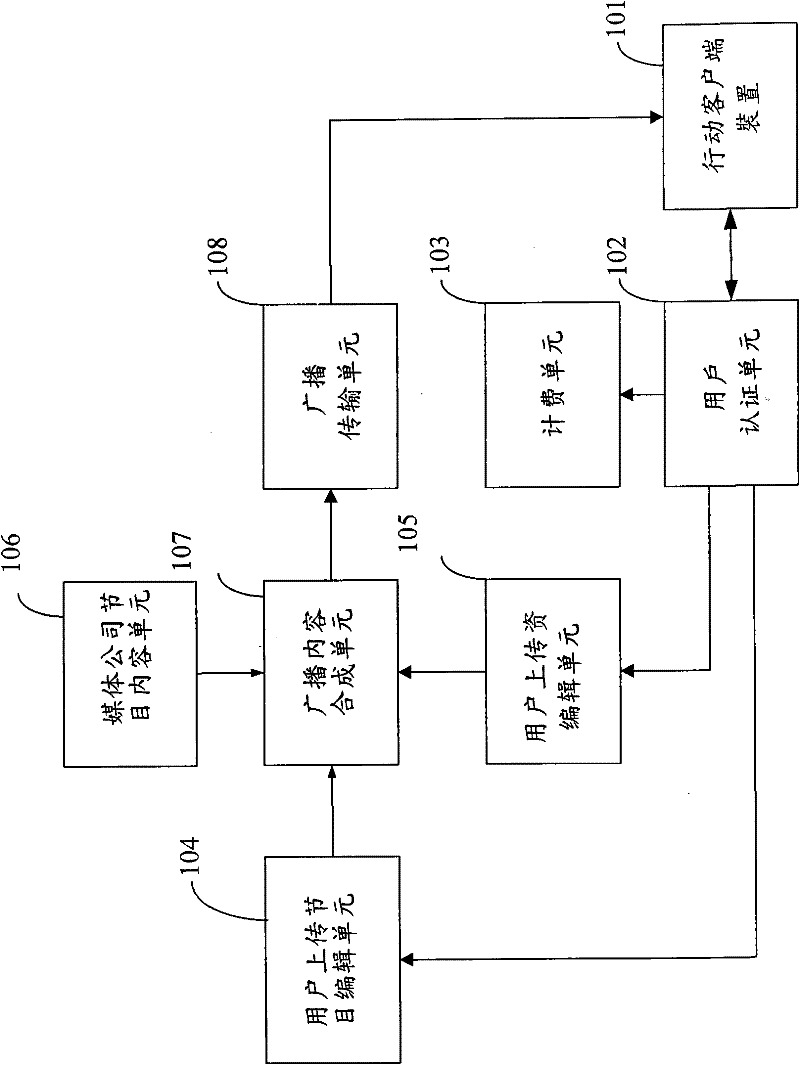

Interactive mobile television system applied to mobile terminal device and method thereof

InactiveCN101888532AFast updateLow costAnalogue secracy/subscription systemsBroadcast service distributionChat roomTerminal equipment

The invention discloses an interactive mobile television system applied to a mobile terminal device and a method thereof. The interactive mobile television system comprises a mobile client device, a mobile user authentication unit, a charge unit, a user uploaded program editing unit, a user uploaded data editing unit, a media company program content unit, a broadcast content synthesizing unit and a broadcast transmission unit. The invention provides an active mobile television system which is actively participated by audiences, applied to mobile television communities, provided with value-added services, mainly applied to the mobile terminal device and provided with interactive multi-media services; and furthermore, the interactive mobile television service is further integrated with a mobile chat room to provide relevant application in the aspect of the communities, and provides an interactive platform for the audiences who watch the same program by combining the mobile television service with the mobile chat room.

Owner:CHUNGHWA TELECOM CO LTD

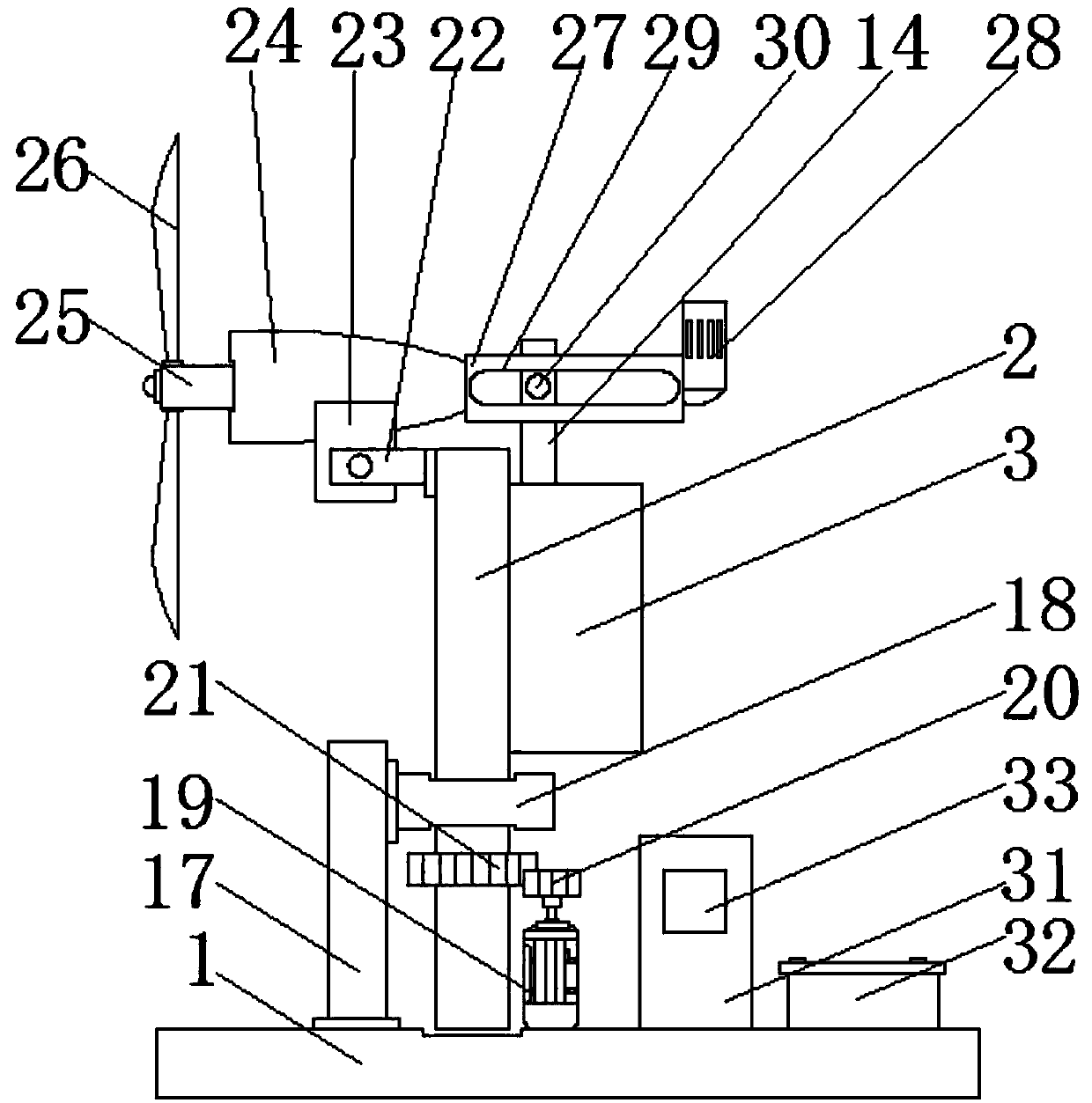

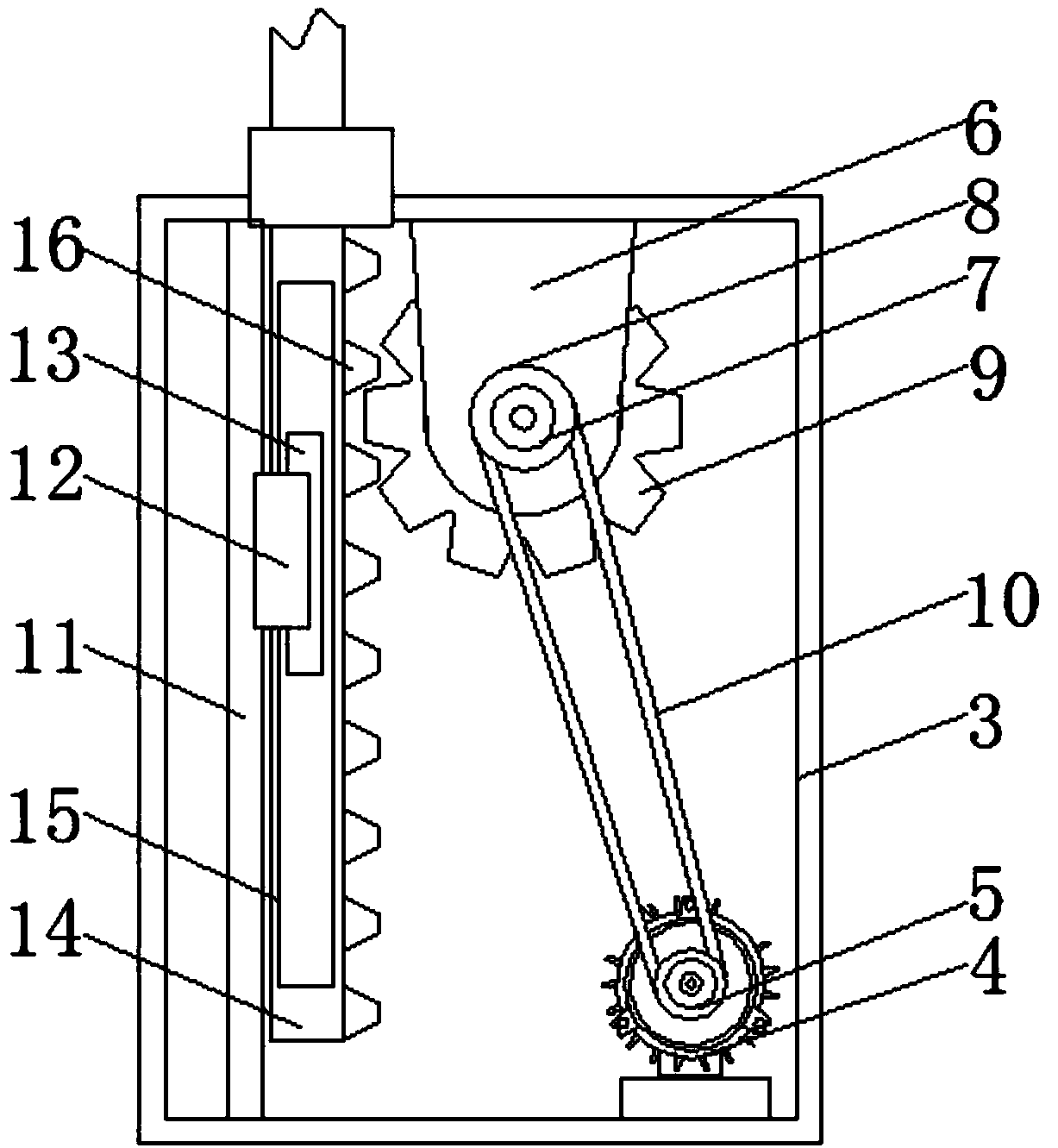

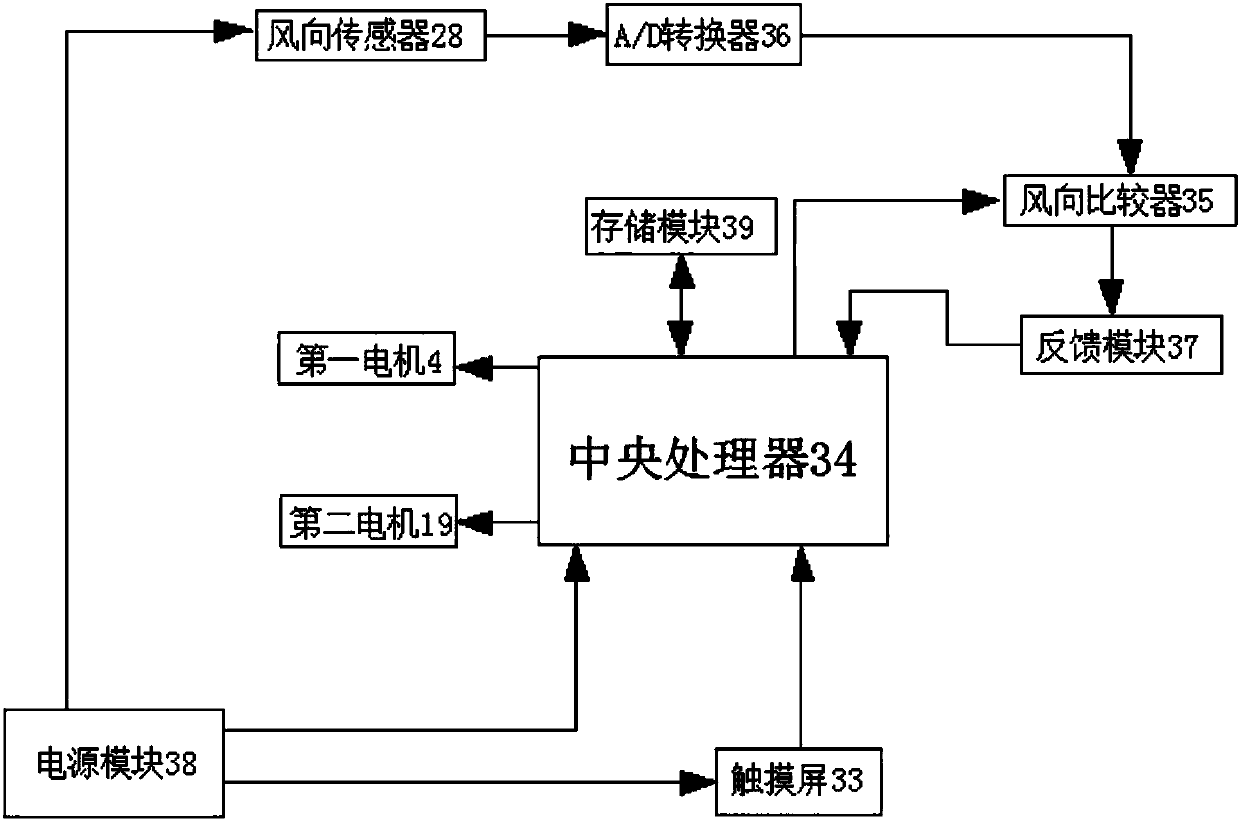

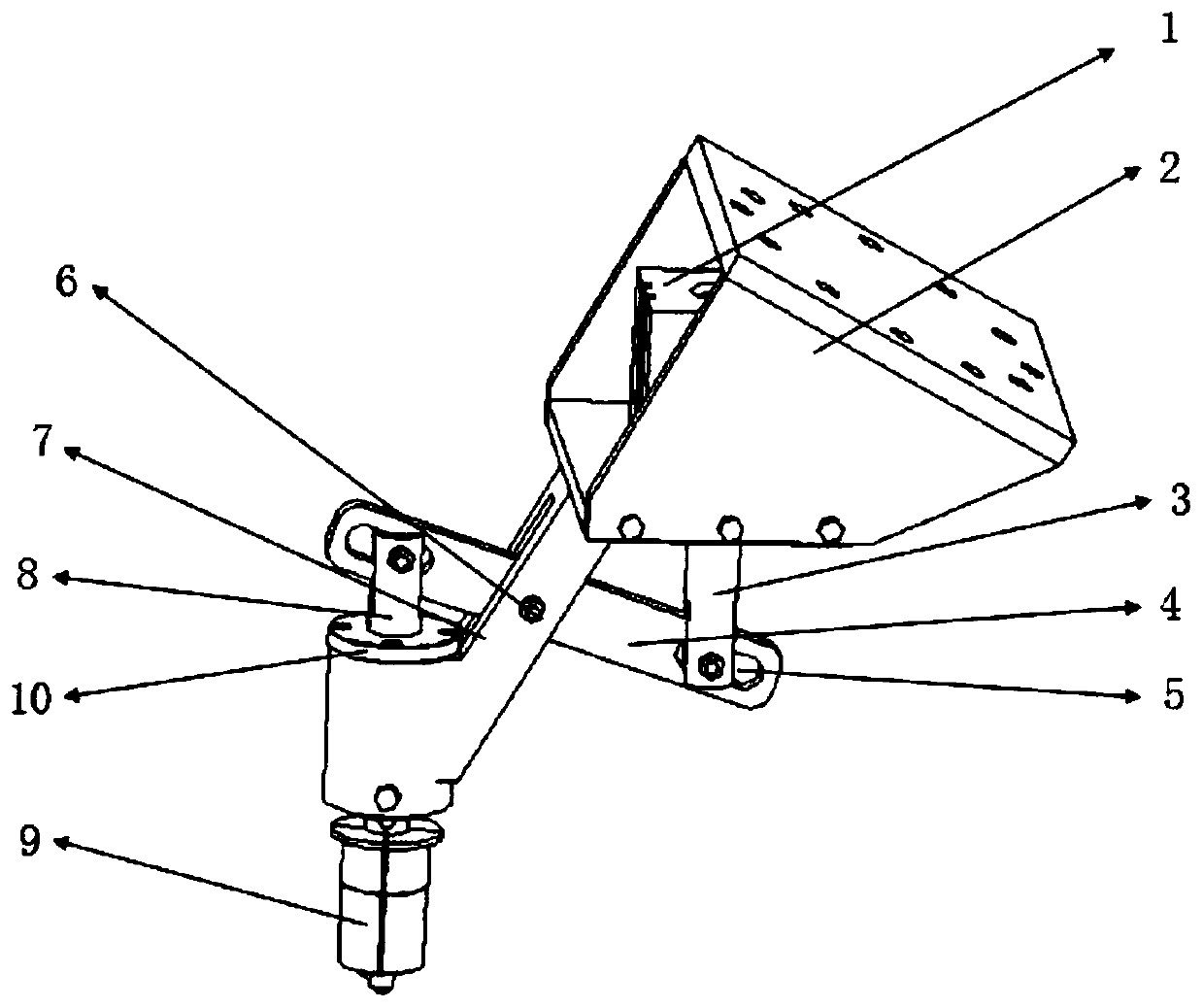

Wind generating set capable of adjusting direction automatically

InactiveCN107905953AImprove power generation efficiencyAvoid damage phenomenonWind motor controlMachines/enginesWind drivenCoupling

The invention discloses a wind generating set capable of adjusting a direction automatically, and relates to the technical field of new energy resources. The wind generating set comprises a base, thetop of the base is rotatably connected with a rotating rod, and one side of the surface of the rotating rod is fixedly connected with a machine shell; the bottom of the inner wall of the machine shellis fixedly connected with a first motor, an output shaft of the first motor is fixedly connected with a first belt pulley through a coupling, and the top of the inner wall of the machine wall is fixedly connected with a supporting block; and the interior of the supporting block is rotatably connected with a shaft rod, and the two ends of the shaft rod are rotatably connected with a second belt pulley and a first gear correspondingly. According to the wind generating set capable of adjusting the direction automatically, the problem that a wind generating set cannot adjust the direction according to the wind direction is solved, the power generating efficiency of the wind generating set is improved, the phenomenon that the wind generating set is prone to being damaged due to uneven force isprevented, the service life of wind driven generator equipment is prolonged, the maintenance cost is reduced, and the enterprise benefit is increased.

Owner:安徽锦希自动化科技有限公司

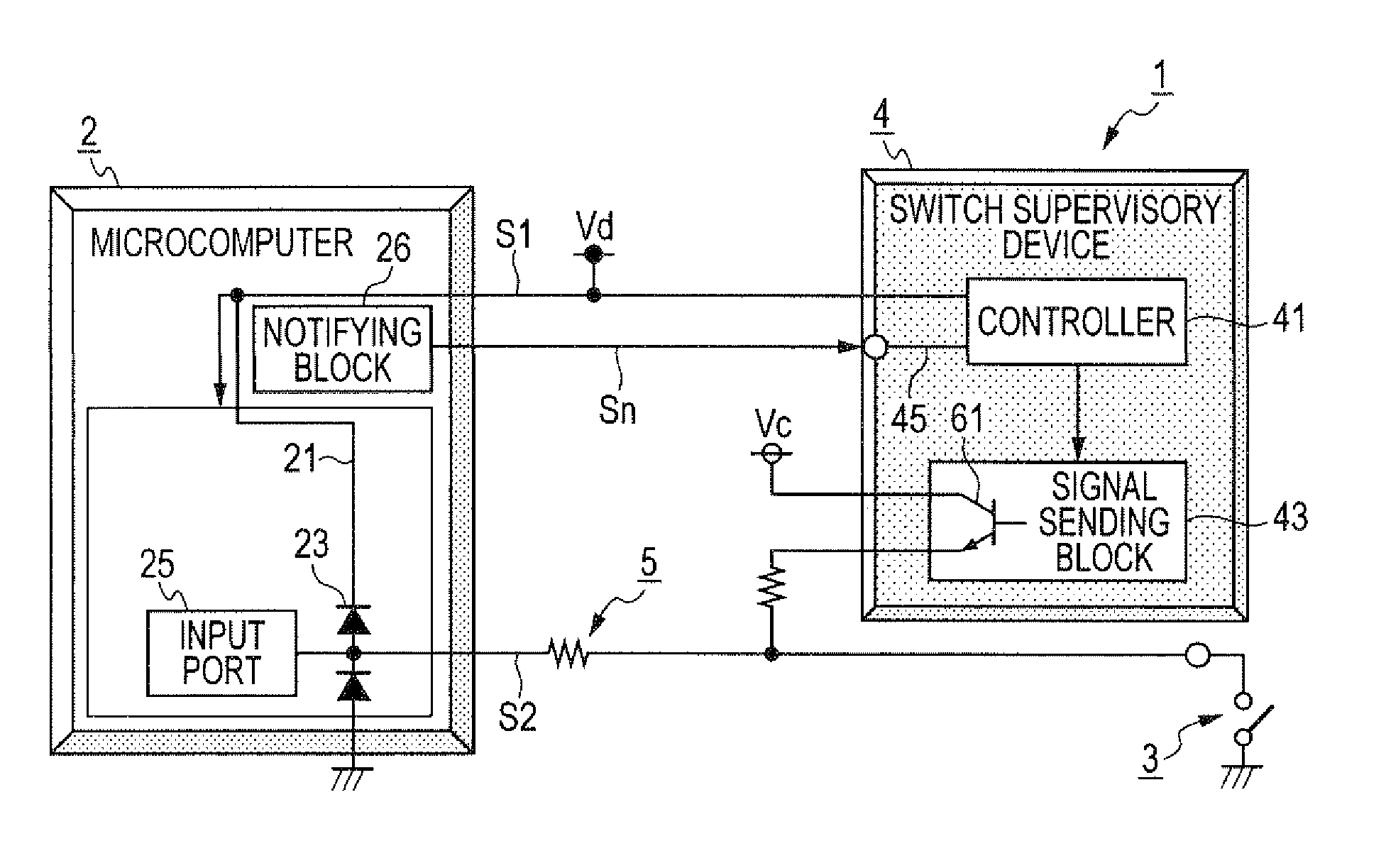

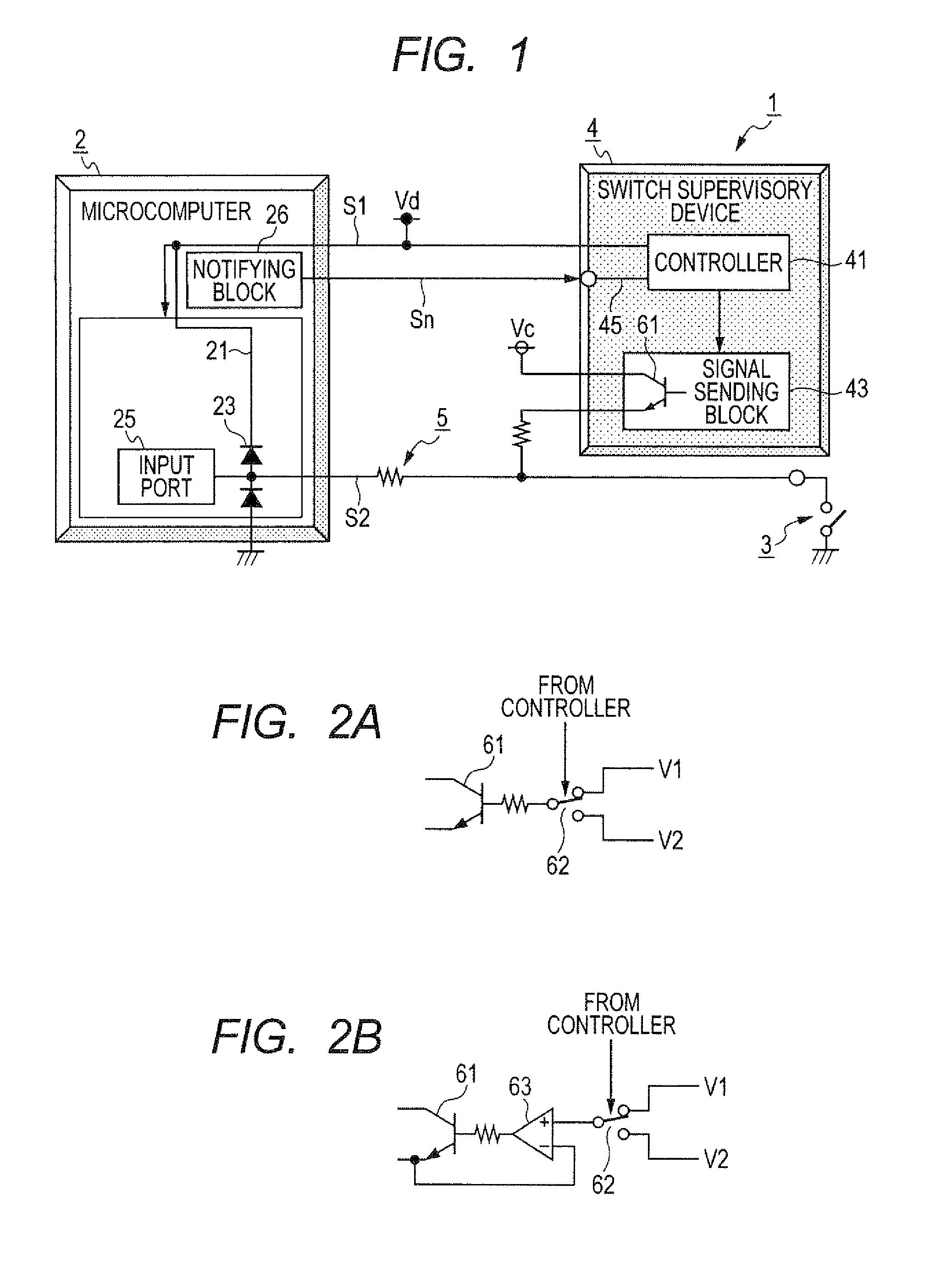

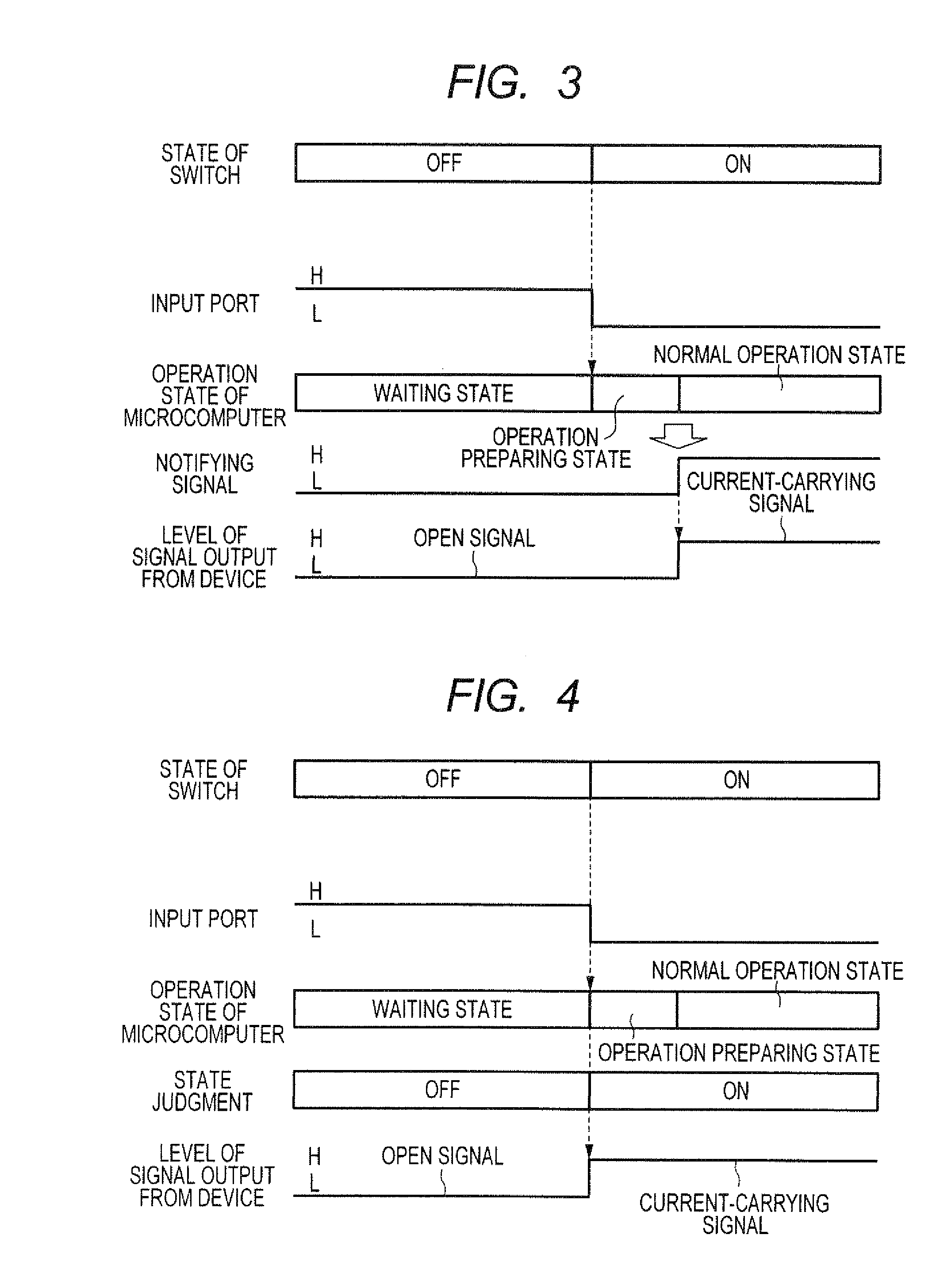

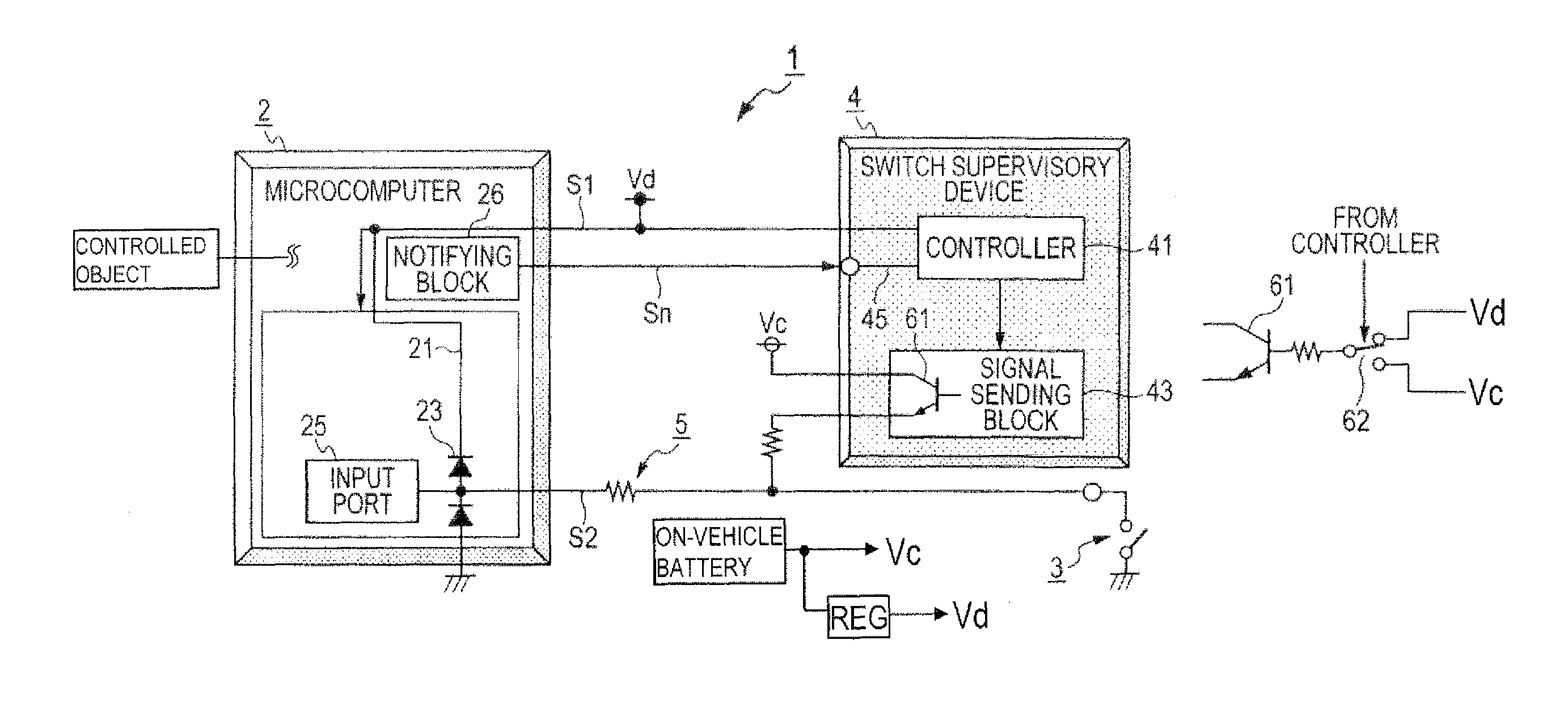

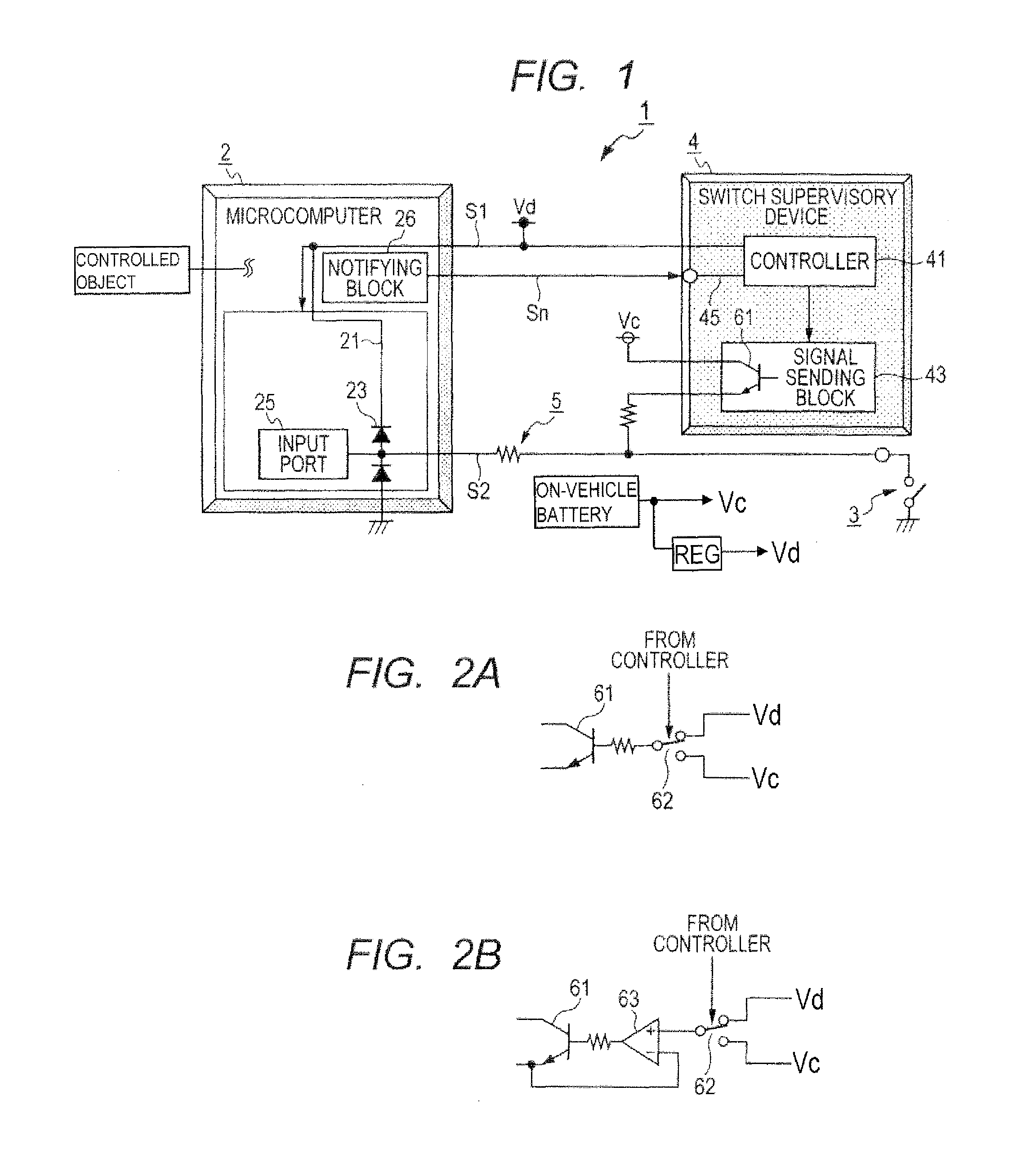

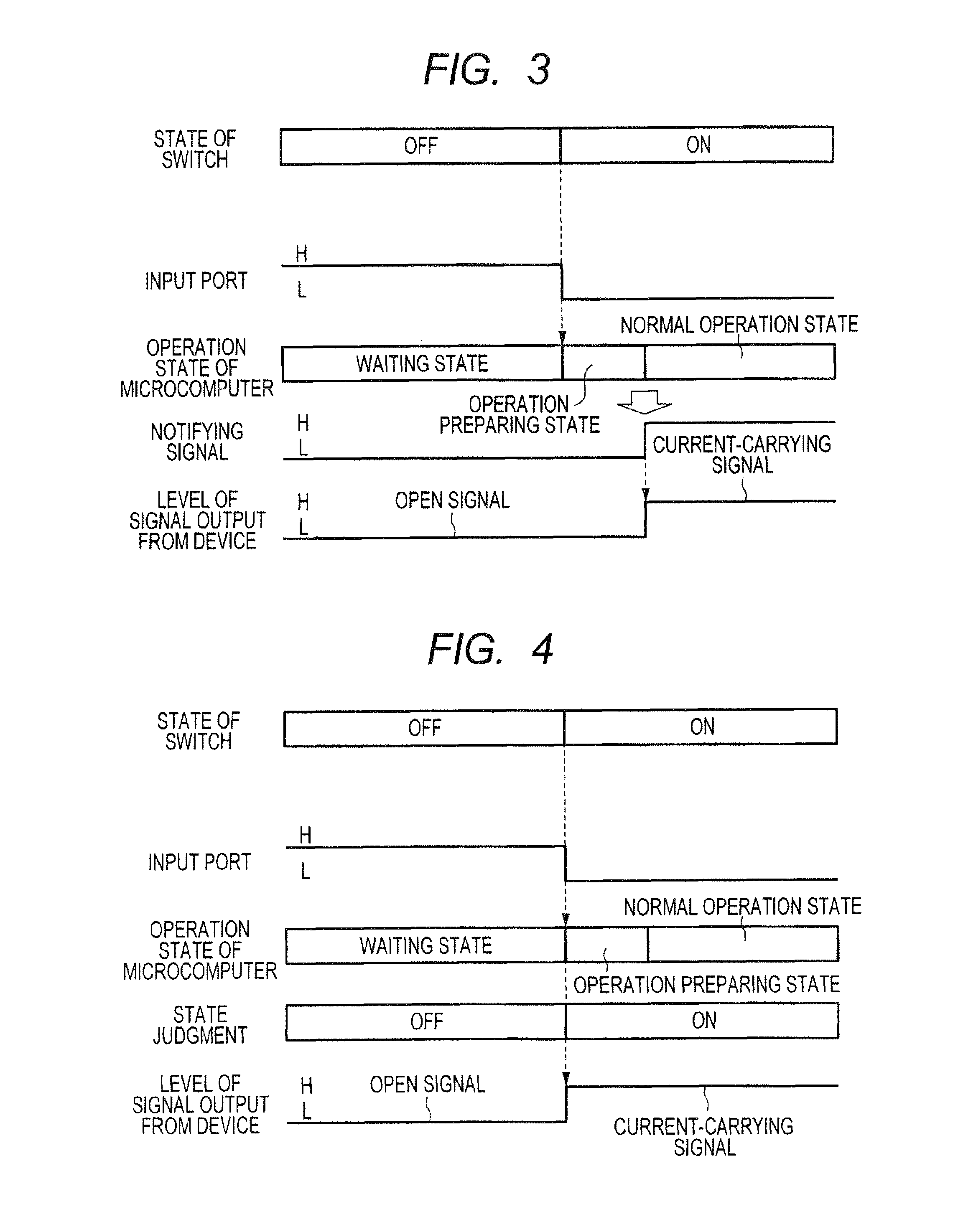

Switch supervision device, control system and control method

ActiveUS20120078384A1Suppresses electric power wastefully consumedReduce high production costsElectric controllersIgnition automatic controlMicrocomputerControl system

A control system has an instruction path of which an object section connects a microcomputer, a switch and a switch supervisory device with one another. The switch sets the path in conductive or non-conductive state on the low side of the microcomputer. An instruction signal is sent to the microcomputer through the conductive path to set the microcomputer in an operation state. When the device judges based on the operation state of the microcomputer that the switch has set the path in a conductive state, the device sends a first signal of first voltage, causing the signal to have current strength equal to or higher than predetermined value in the path, to the object section. When the device judges that the switch has set the path in a non-conductive state, the device sends a second signal of second voltage lower than first voltage to the object section.

Owner:DENSO CORP

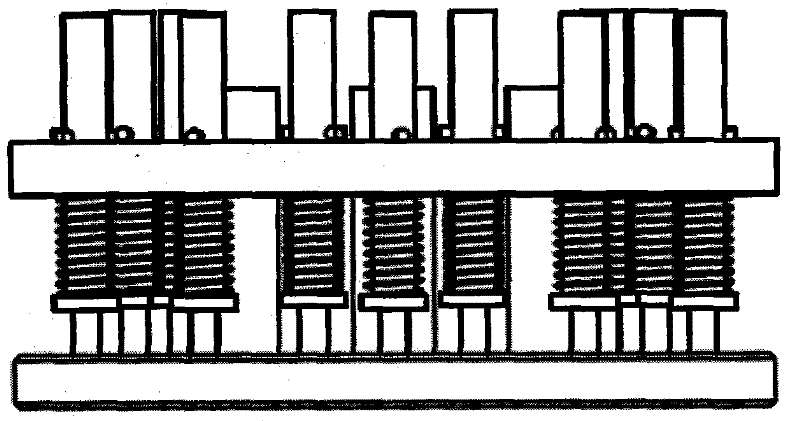

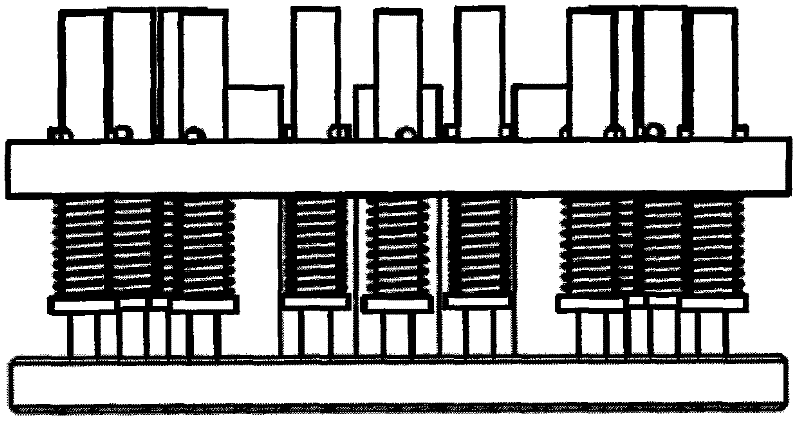

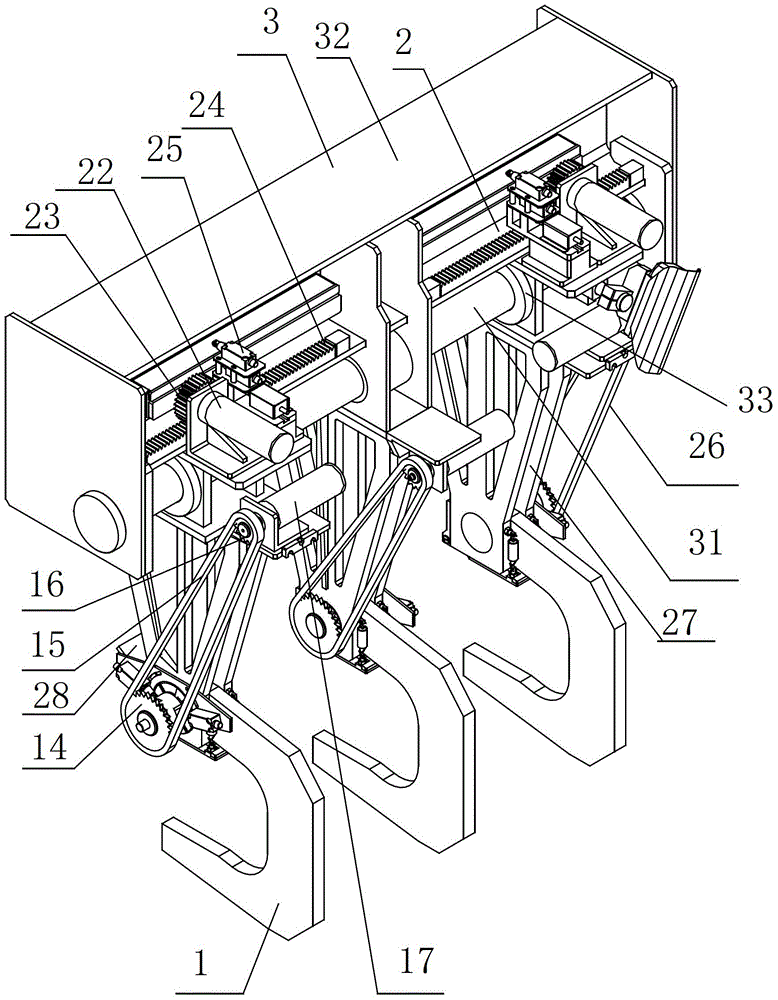

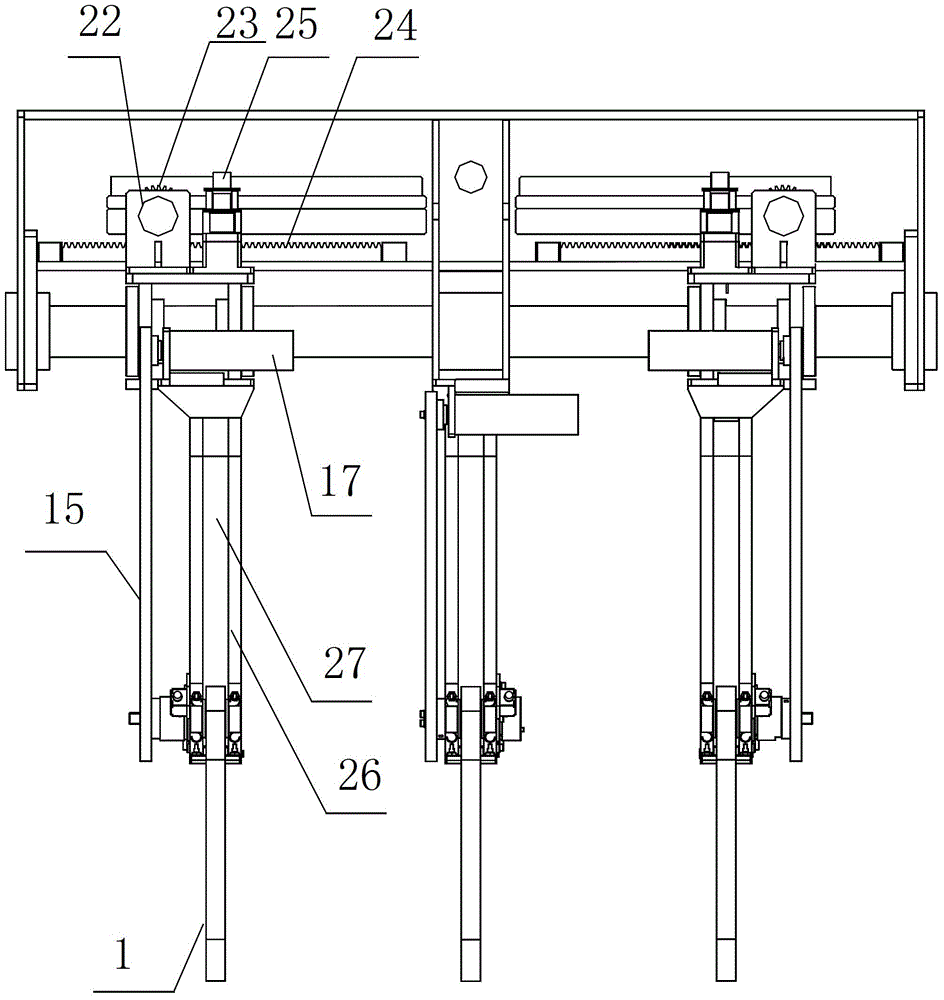

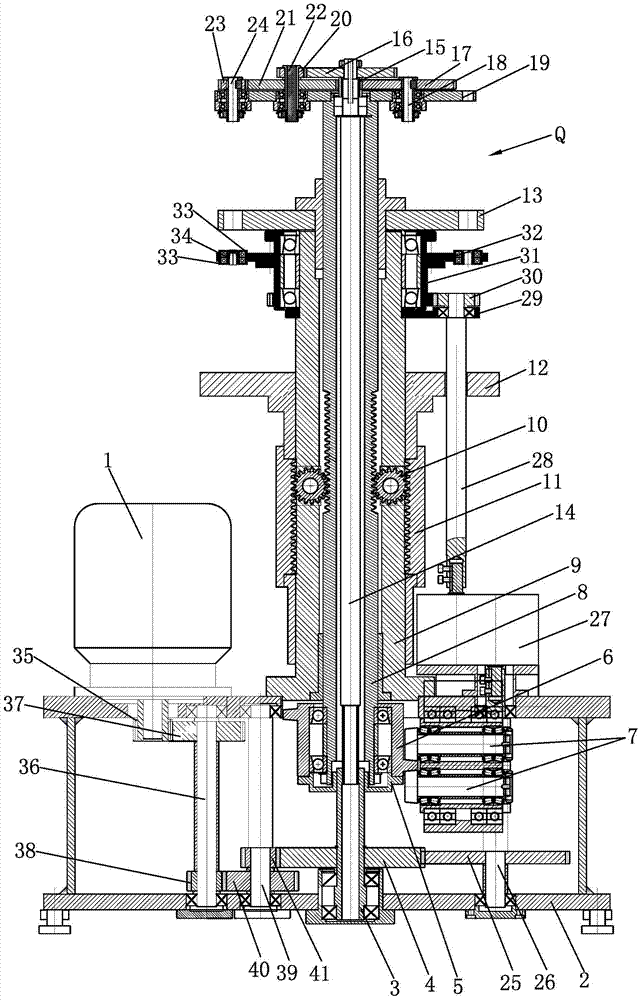

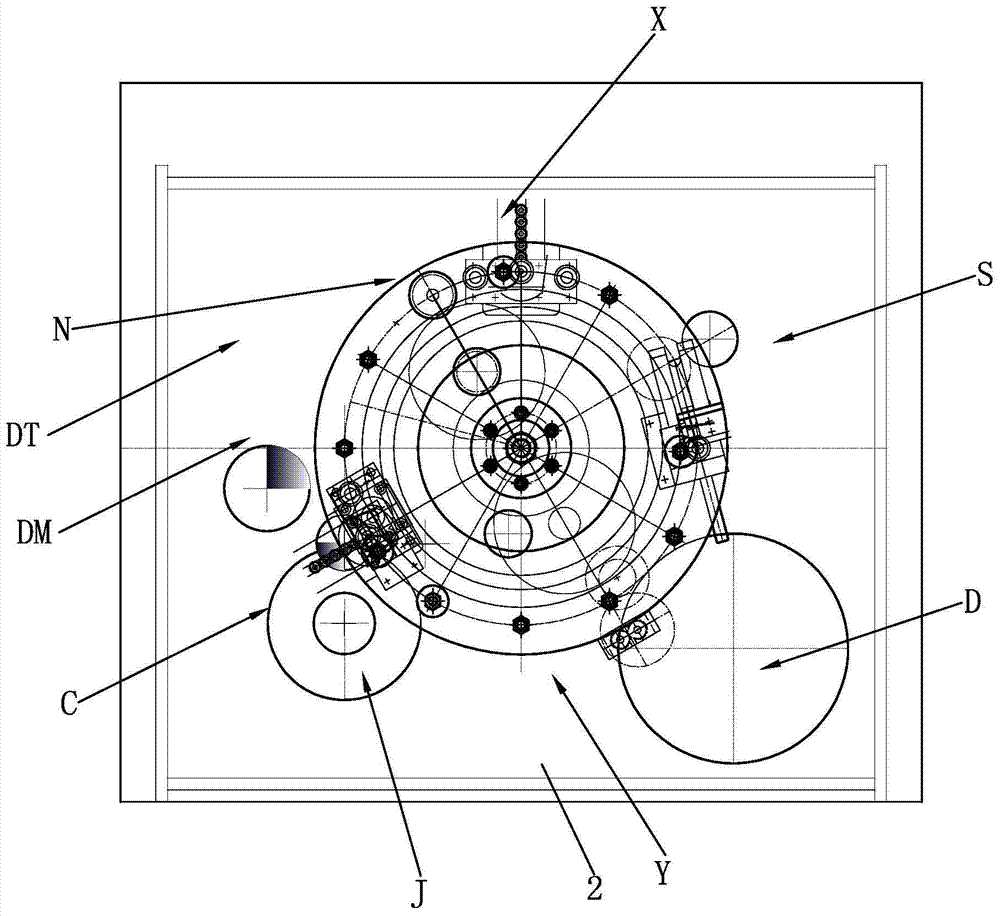

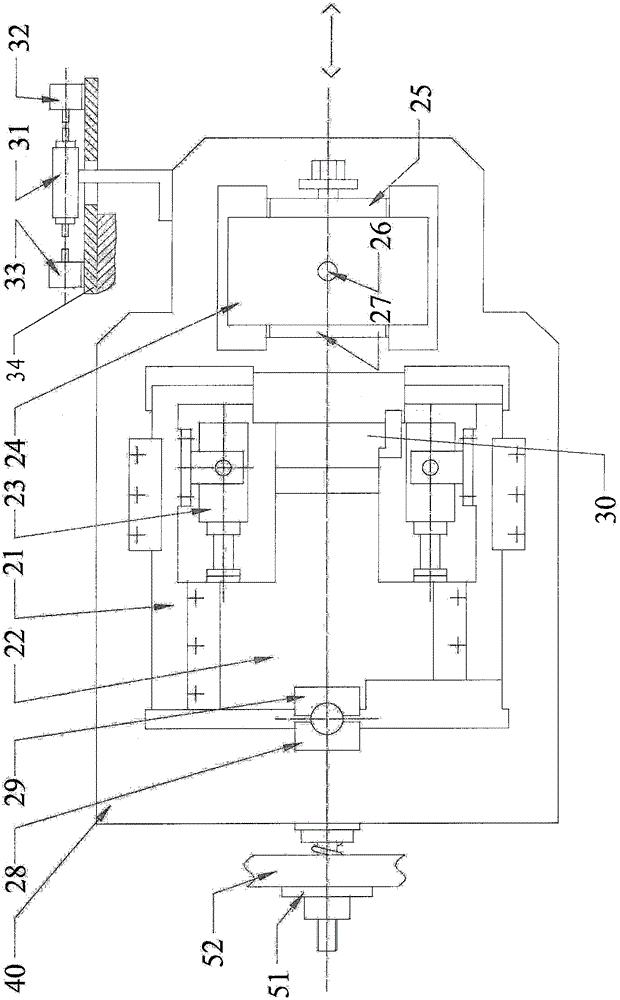

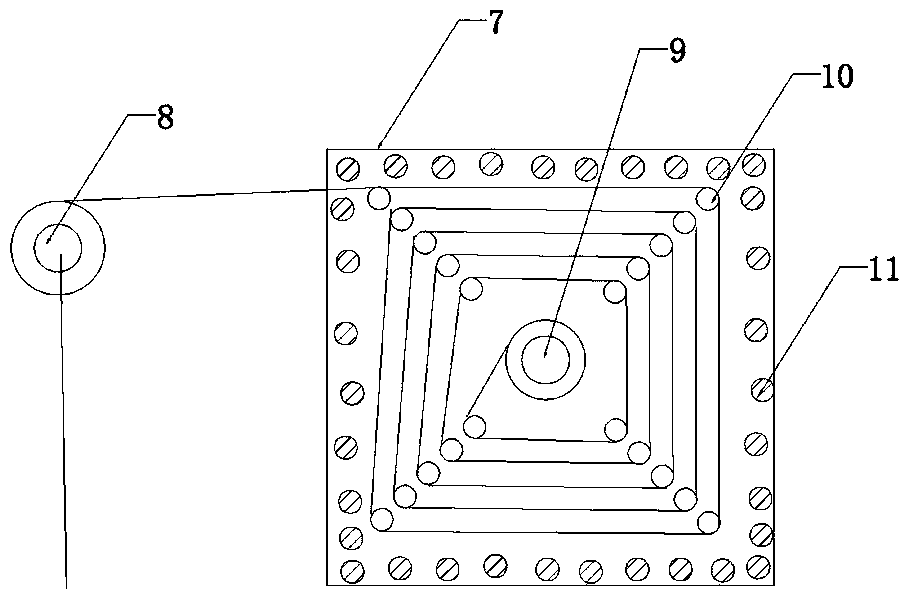

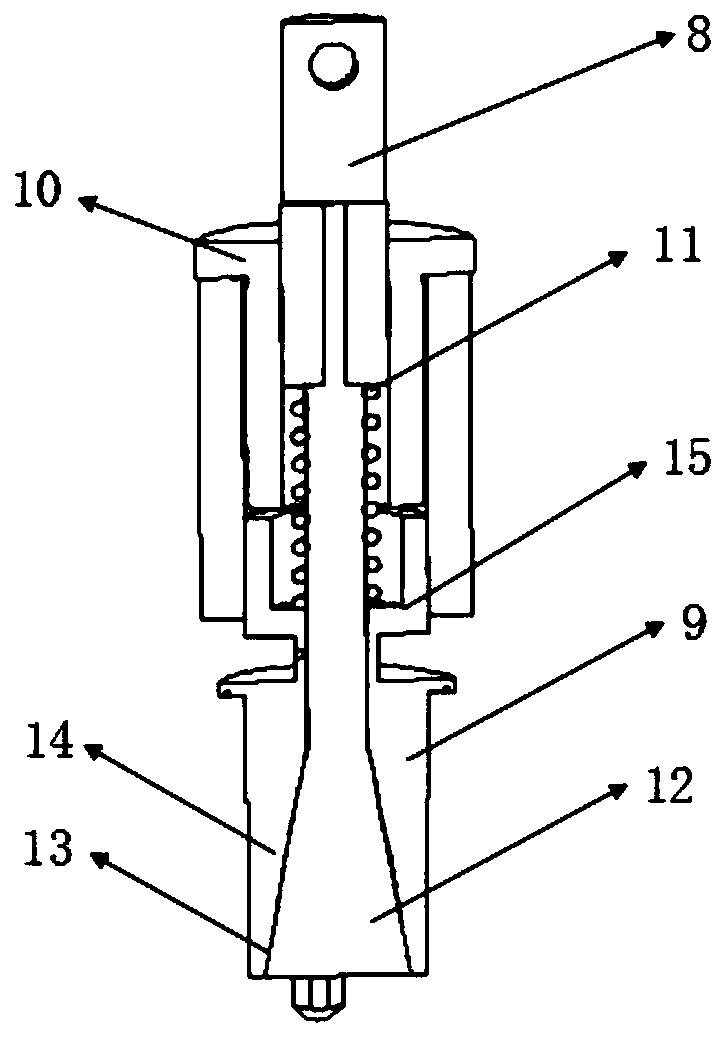

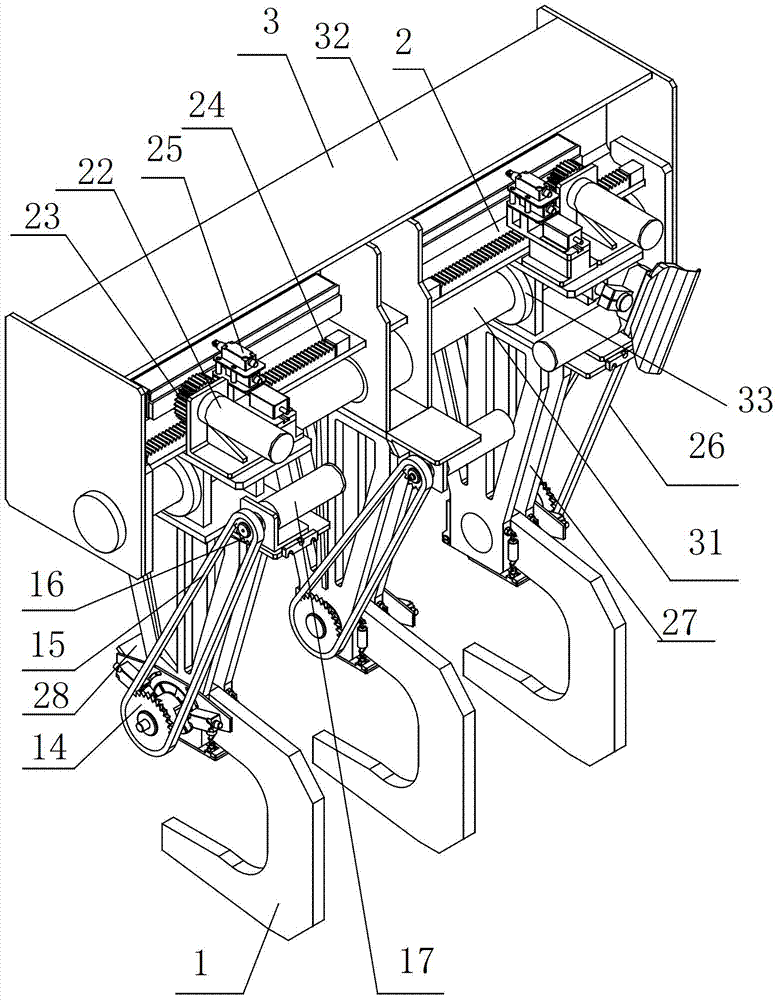

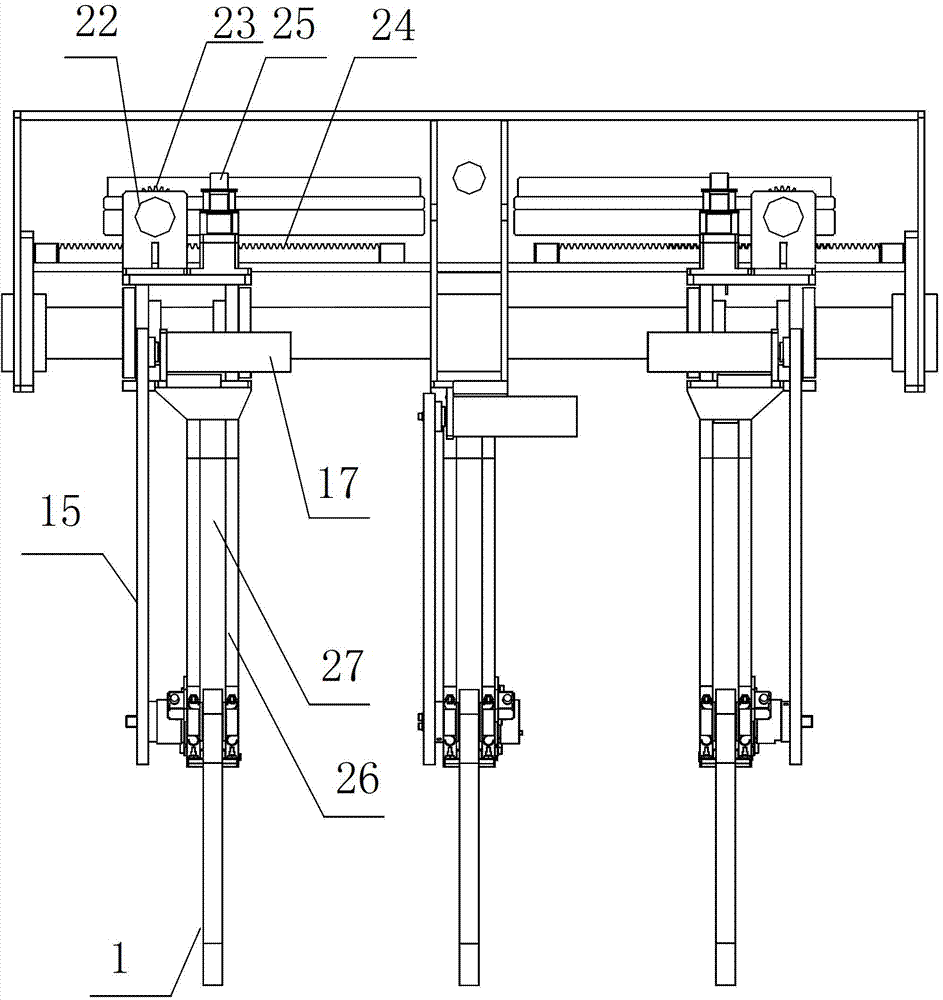

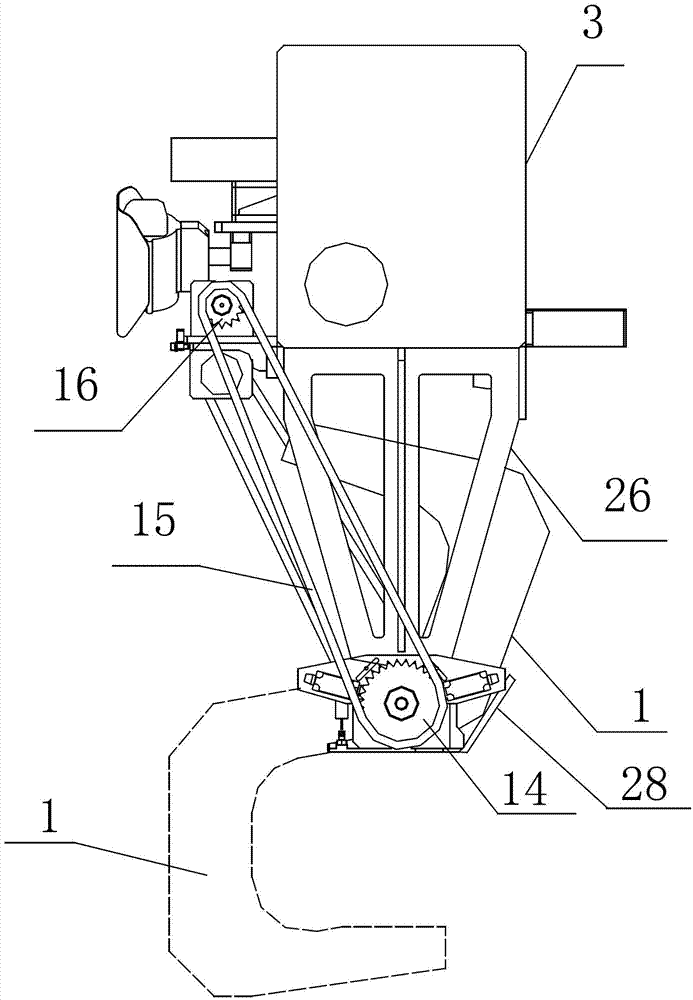

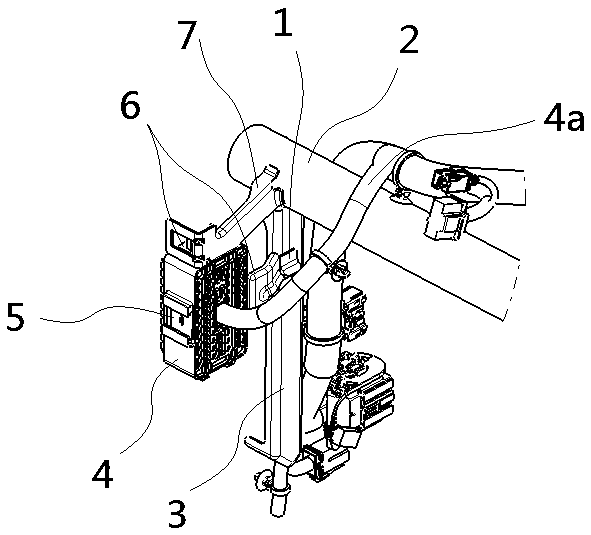

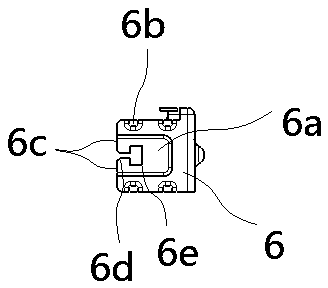

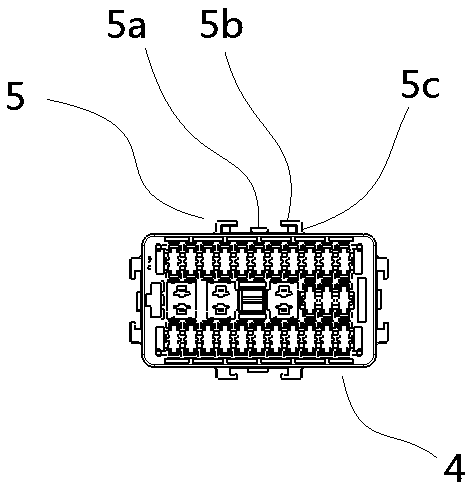

Multi-station capstan press fitting machine

ActiveCN104842141AReduce the difficulty of organizationReduce high production costsMetal working apparatusEngineeringMechanical engineering

The invention discloses a multi-station capstan press fitting machine. The multi-station capstan press fitting machine is characterized in that the multi-station capstan press fitting machine comprises a driving mechanism and an upper shell component, the upper shell component is used for feeding bullet casings into bullet casing sleeves, a primer pressing component is used for pressing primers on the bullet casings, a detection component is used for detecting whether the primers are pressed in place or not, and a waste elimination component is used for eliminating the primers not subjected to complete primer pressing; a riveting component is used for riveting the primers subjected to complete primer pressing on the bullet casings, a bottom gluing component is used for gluing bottom surfaces of contacts surfaces between the primers and the bullet casings, an inner opening gluing component is used for gluing inner walls of the bullet casings, and a discharge component is used for outputting the bullet casings with the primers. The multi-station capstan press fitting machine has the advantages that original nine decentralized procedures are completed by a special machine, so that production organization difficulty is lowered greatly, press fitting efficiency is improved and production cost is reduced; moreover, the multi-station capstan press fitting machine is simple in structure and easy to operate.

Owner:CHONGQING INST OF MECHANICAL & ELECTRICAL ENG

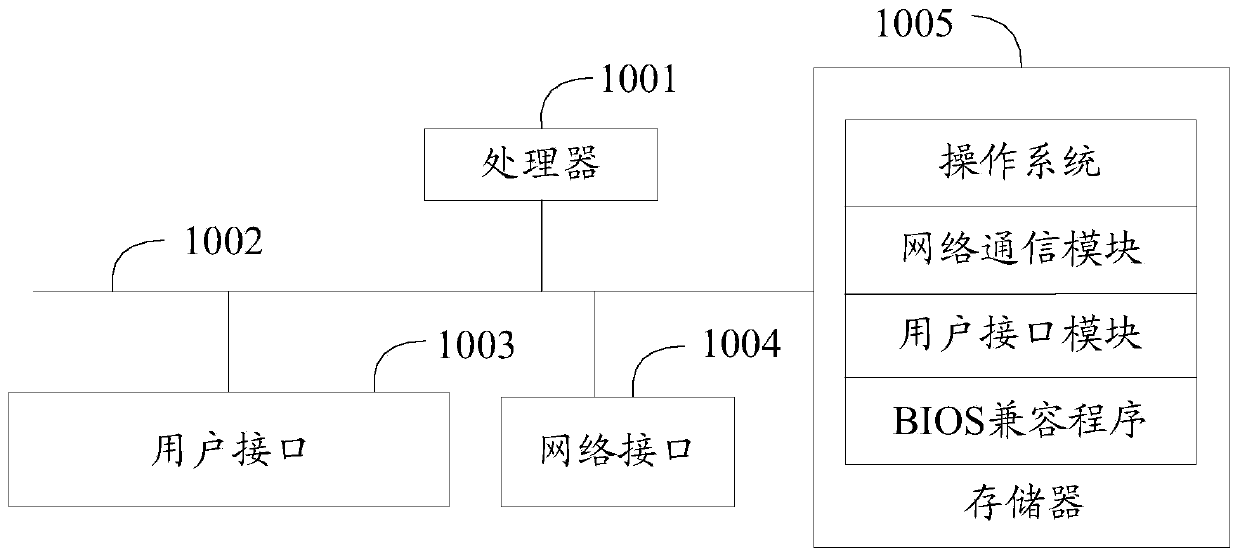

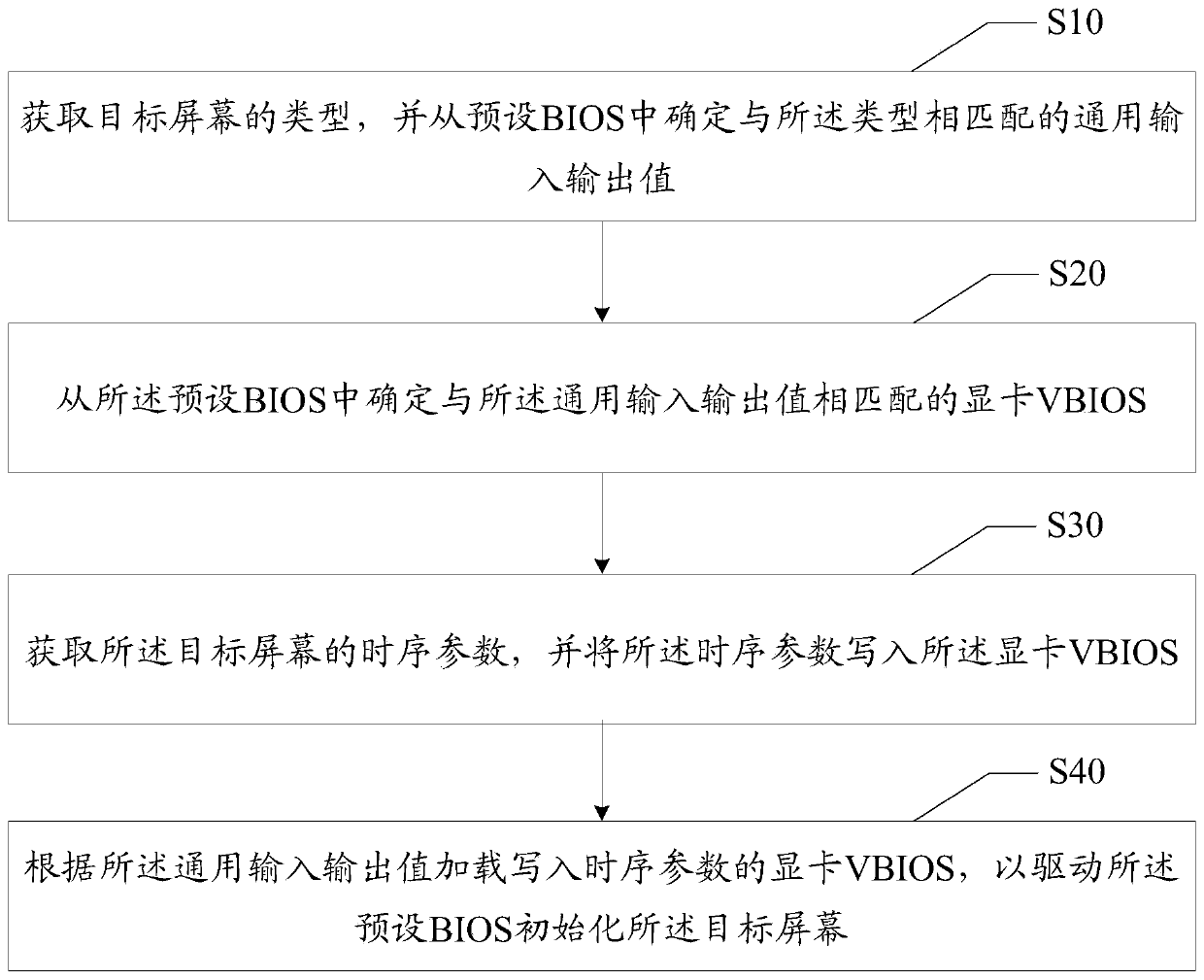

BIOS compatibility method and device without EDID screen, terminal and computer storage medium

The invention discloses a BIOS compatibility method and device without an EDID screen, a terminal and a computer storage medium. The BIOS compatible method without the EDID screen is applied to a terminal and comprises the steps of acquiring the type of a target screen and determining a universal input and output value matched with the type from a preset BIOS; determining a video card VBIOS matched with the universal input / output value from the preset BIOS; acquiring a time sequence parameter of the target screen, and writing the time sequence parameter into the video card VBIOS; and loading avideo card VBIOS written with a time sequence parameter according to the universal input / output value so as to drive the preset BIOS to initialize the target screen. The technical problems that in the prior art, the product quality cannot be guaranteed, and the production efficiency is low are solved.

Owner:SHENZHEN HAILINKE INFORMATION TECH CO LTD

Electrostatic spraying method of shell of outdoor unit of air conditioner

InactiveCN104689956AReduce high production costsImprove spraying effectLiquid surface applicatorsCoatingsEngineeringRooming-in

The invention provides an electrostatic spraying method of a shell of an outdoor unit of an air conditioner. The method includes the steps of checking incoming material, to be specific, checking the appearance of the shell entering a powder house, and cleaning the powder house to keep it clean; checking a powder supply system and a recovery system in the powder house and a spray gun unit to make sure all devices run well; moving the shell into a painting room in the powder house, and spraying the shell; before spraying, cleaning accumulated powder in the spray gun unit and the powder supply system with dry compressed air to make sure that the powder is evenly atomized, and allowing a worker to adjust distances from different workpieces to the spray gun unit; checking the sprayed shell for discharging, and detecting a coating every 20 min with a thickness meter. The method has the advantages that high production cost of workpieces caused by misoperation is effectively reduced, productivity is effectively guaranteed by providing regular check steps, the method is simple to operate, and spraying effect of the shell of the outdoor unit of the air conditioner is evidently improved.

Owner:WUHU XIECHENG METAL PROD

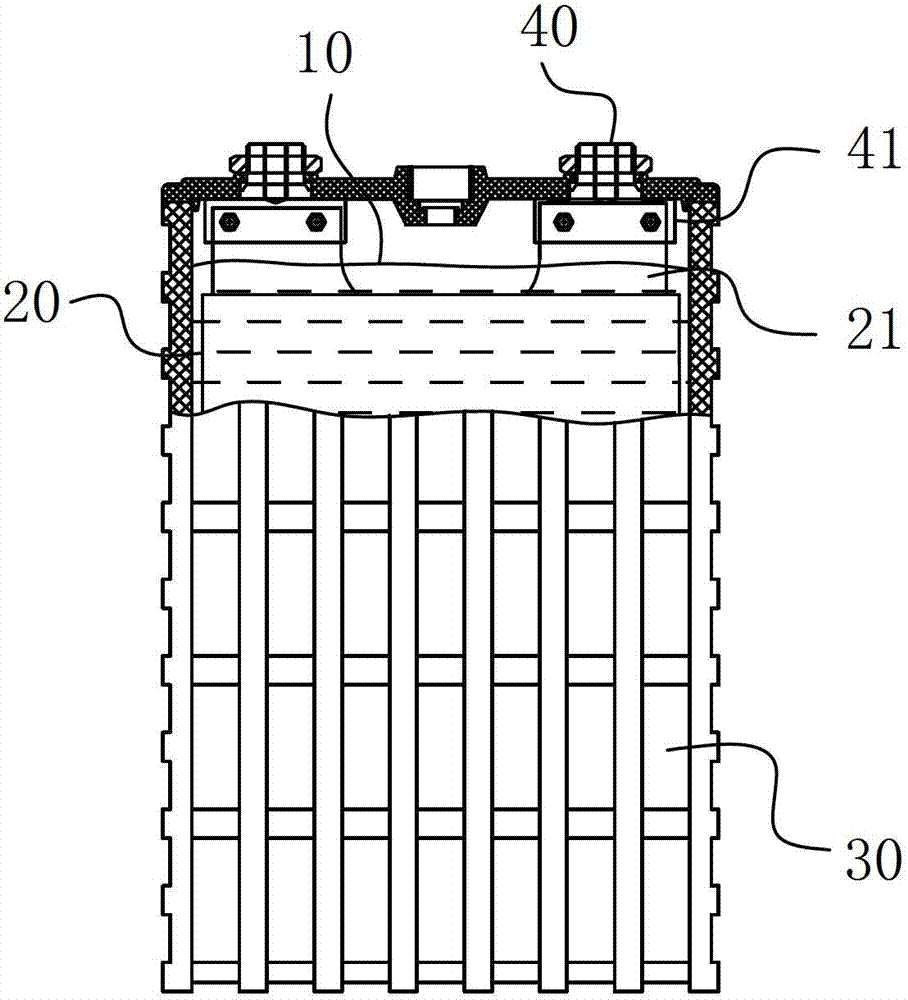

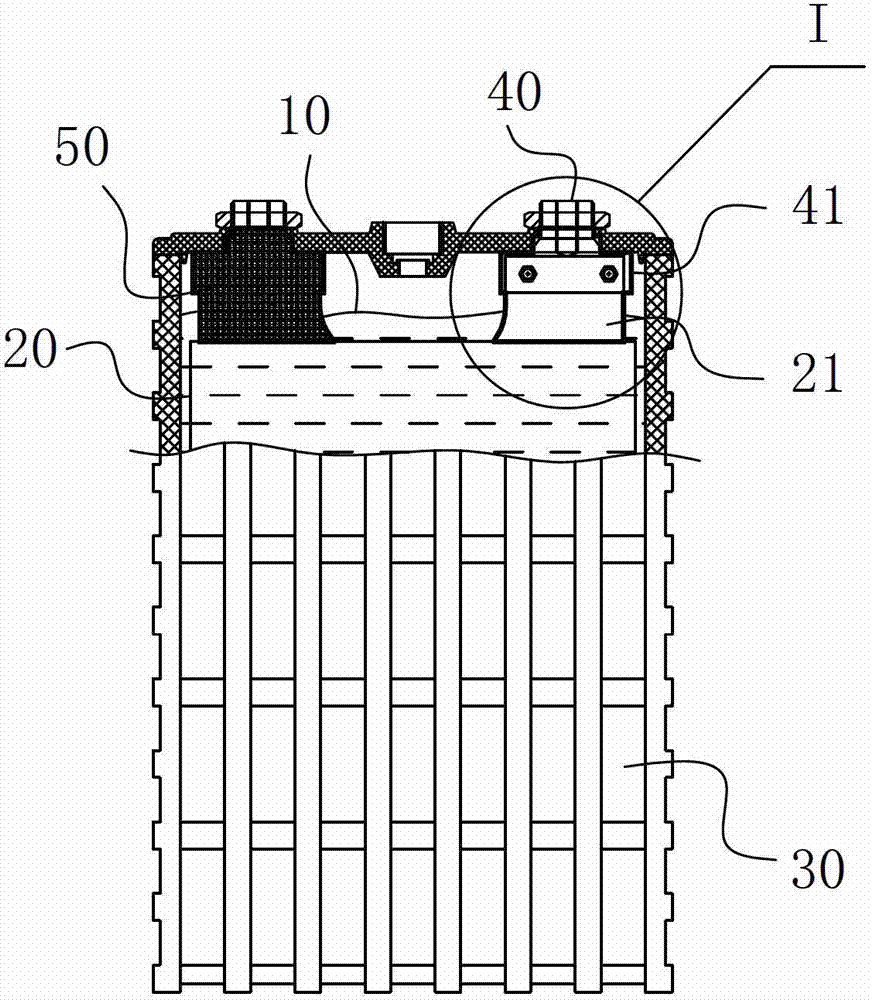

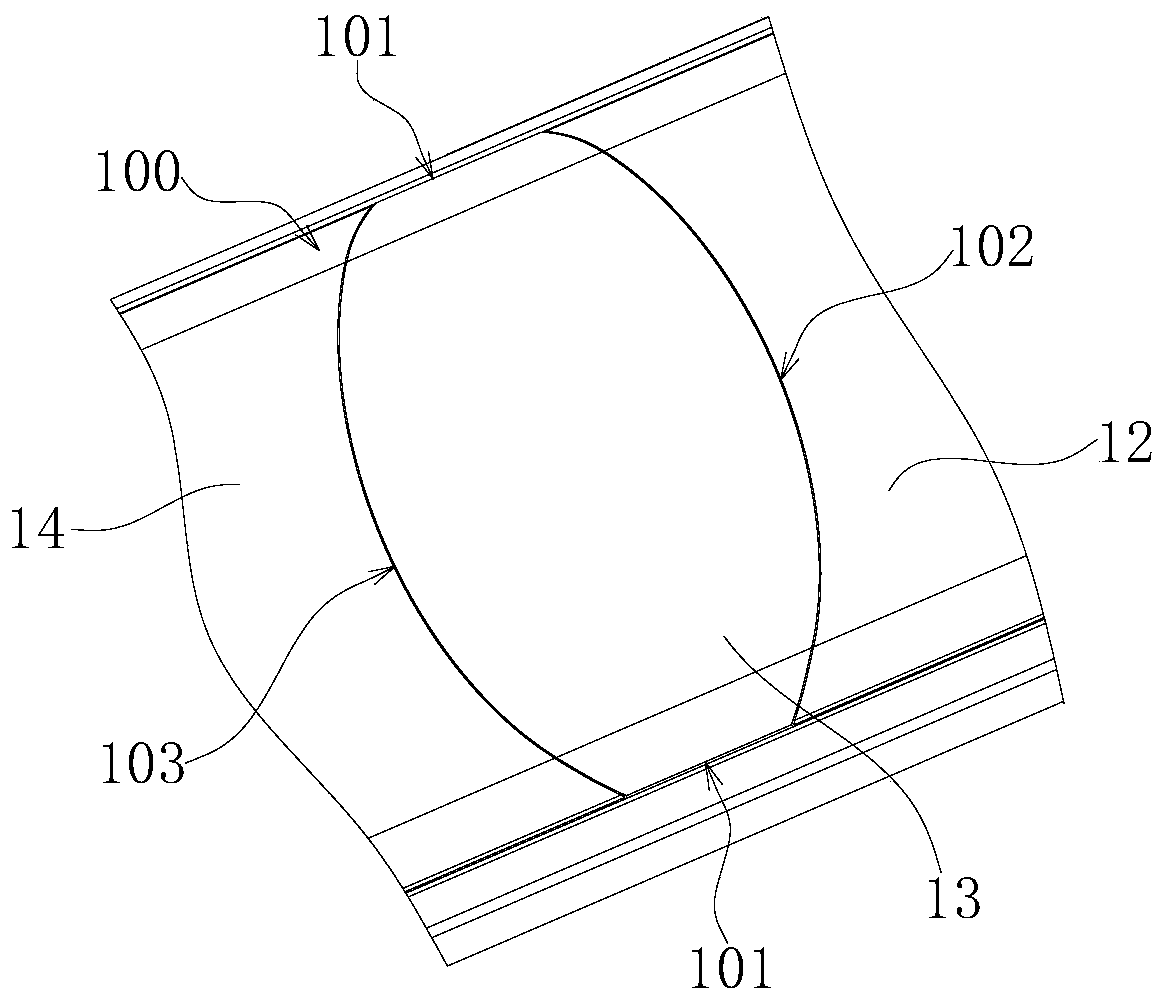

Lithium ion battery

ActiveCN102956853AReduce micro-short circuit phenomenonShorten aging timeFinal product manufactureCell component detailsInsulation layerInternal resistance

The invention belongs to the field of batteries, and specifically relates to a lithium ion battery. The lithium ion battery provided by the invention comprises an electrolytic solution, a current collector and a battery box, as well as positive and negative pole columns which penetrate through the wall of a battery box from inside to outside and are used for leading current out, and the positive and negative pole columns comprise an inner pole column positioned on the inner cavity of the battery box and at a wall thickness region and an outer pole column extending out of the battery box; and the current collector is convexly provided with a pole ear in an extending manner, the pole ear and the inner pole column are fixedly connected and arranged, and a sealed insulation layer covers the part of the pole ear, the inner pole column and a joint between the pole ear and the inner pole column, which at least contacts with the electrolytic solution. The lithium ion battery provided by the invention has the advantages that the structure is simple, an electroplating phenomenon is effectively buffered, the charge-discharge efficiency of the lithium battery is improved, the oscillation of a contacting ohm internal resistance of the battery is effectively restrained, and the use consistency of the battery is improved; and the cycling life of the battery is greatly prolonged, the high manufacturing cost of the lithium ion battery at present is effectively reduced, and finally, the lithium ion battery provides a guarantee for manufacturers to rapidly expand the market.

Owner:HEFEI HENGNENG NEW ENERGY TECH

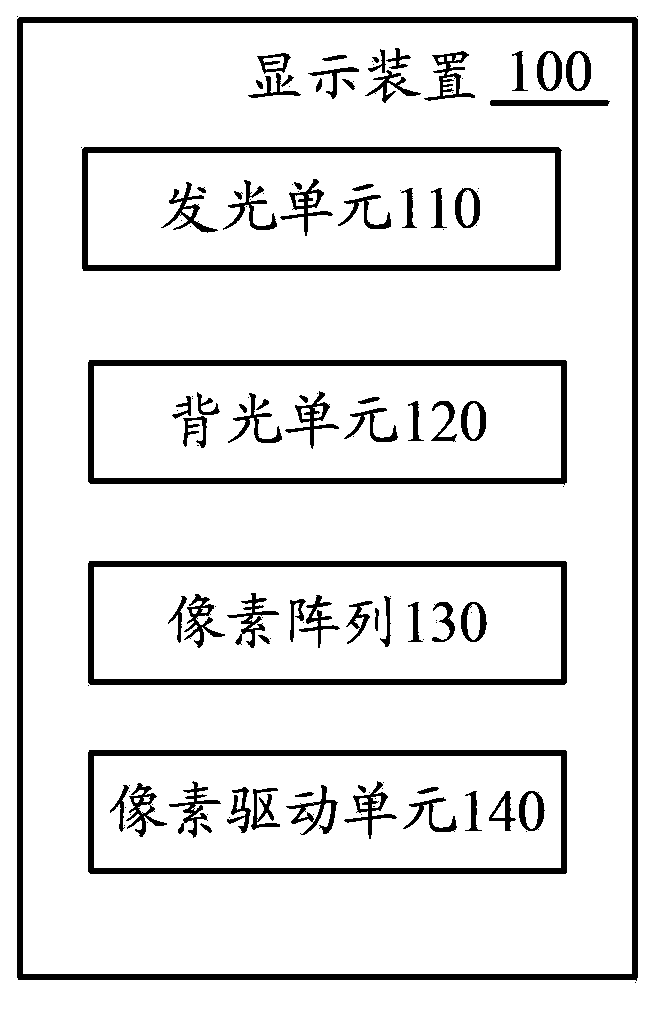

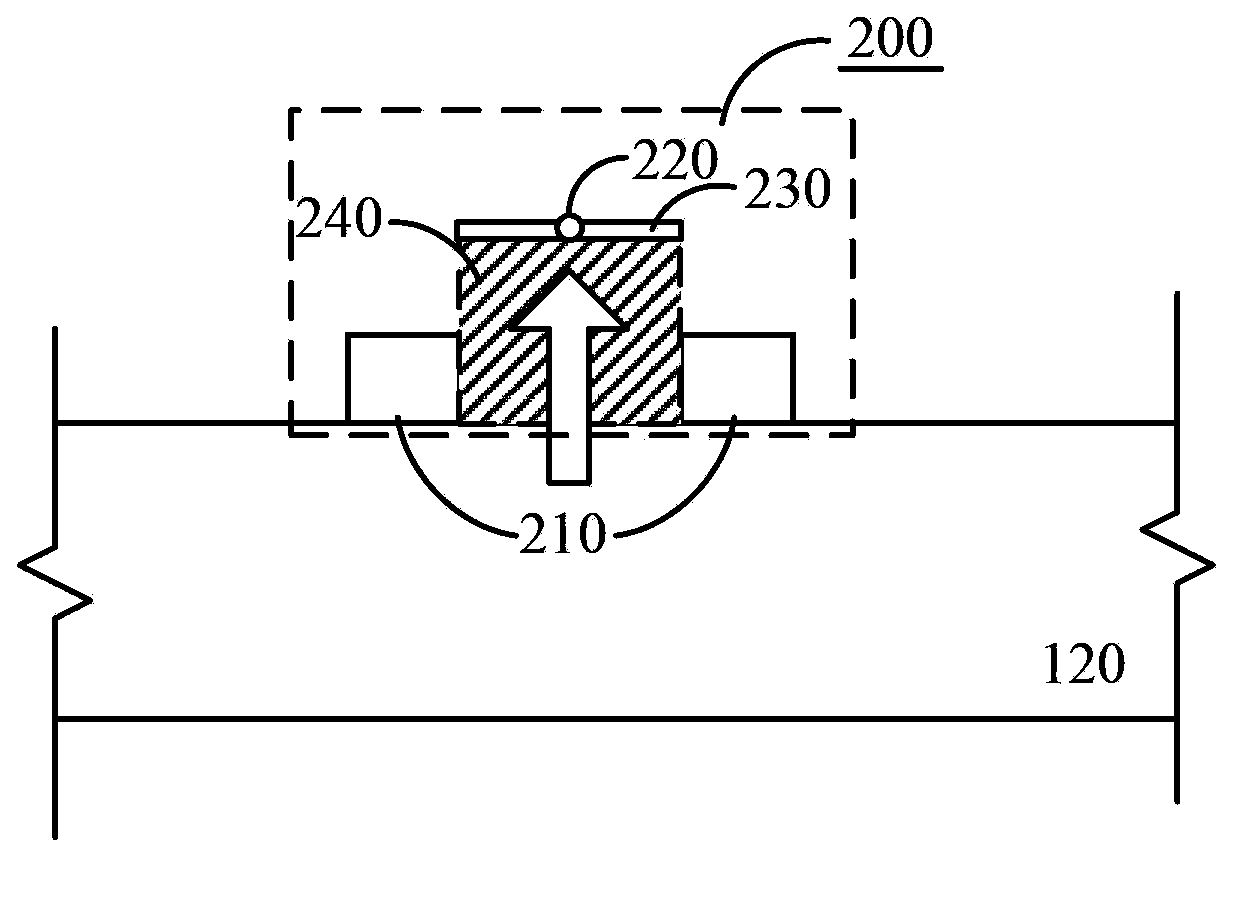

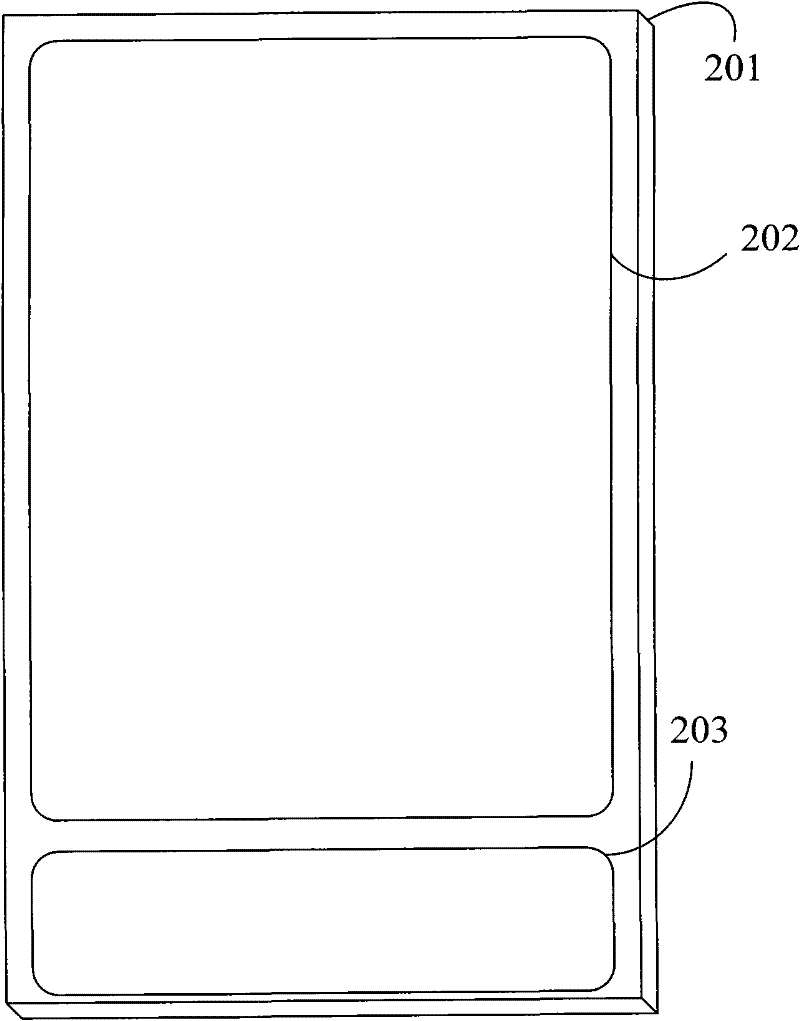

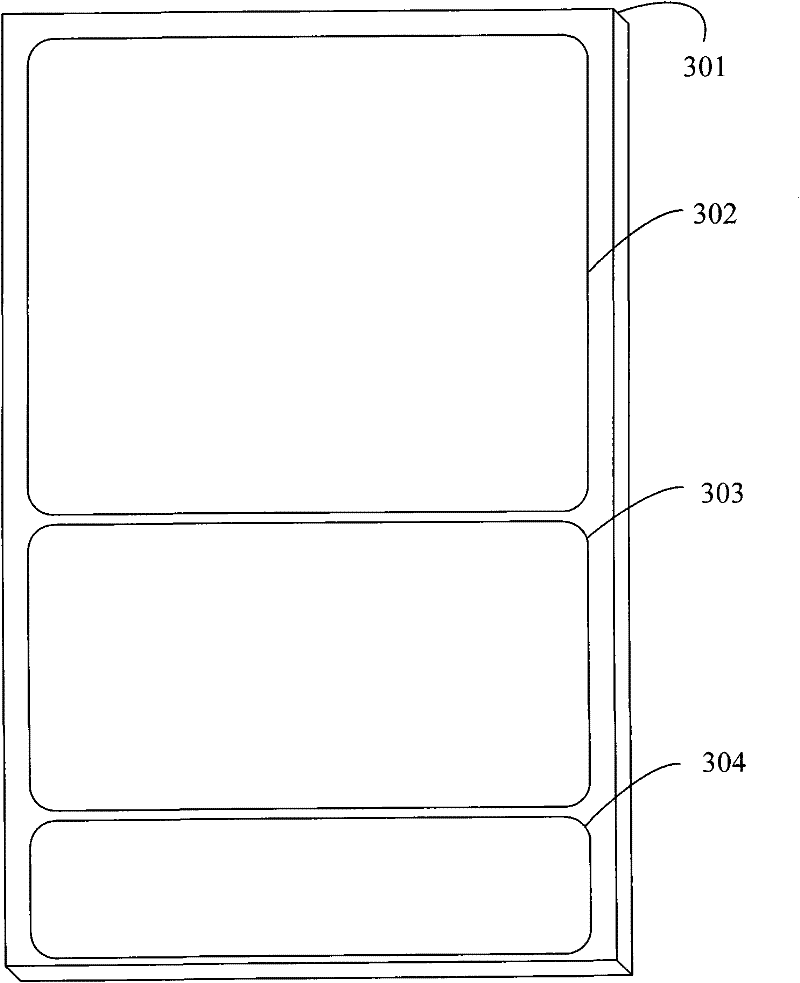

Display device

ActiveCN103676309AIncrease display contrastReduce power consumptionStatic indicating devicesNon-linear opticsPass rateDisplay device

The embodiment of the invention provides a display device which comprises a light-emitting unit, a backlight unit, a pixel array, and a pixel drive unit. The light-emitting unit is arranged on one side of the backlight unit and used for emitting light to the backlight unit, the pixel array is arranged on the backlight unit and comprises a plurality of pixel units, the pixel drive unit is used for obtaining an image to be displayed and generating control commands for all pixel units according to the image to be displayed, the backlight unit is used for sending light emitted from the light-emitting unit to the pixel array, and each pixel unit determines the passing rate of light sent by the backlight unit at the corresponding pixel unit according to the control commands.

Owner:LENOVO (BEIJING) LTD

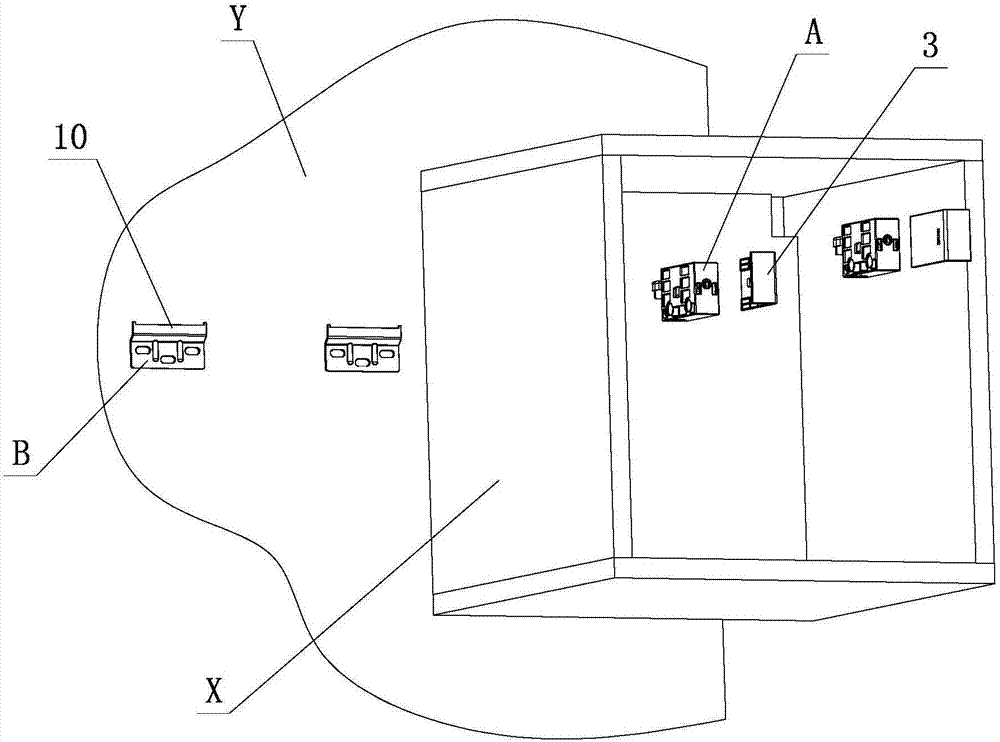

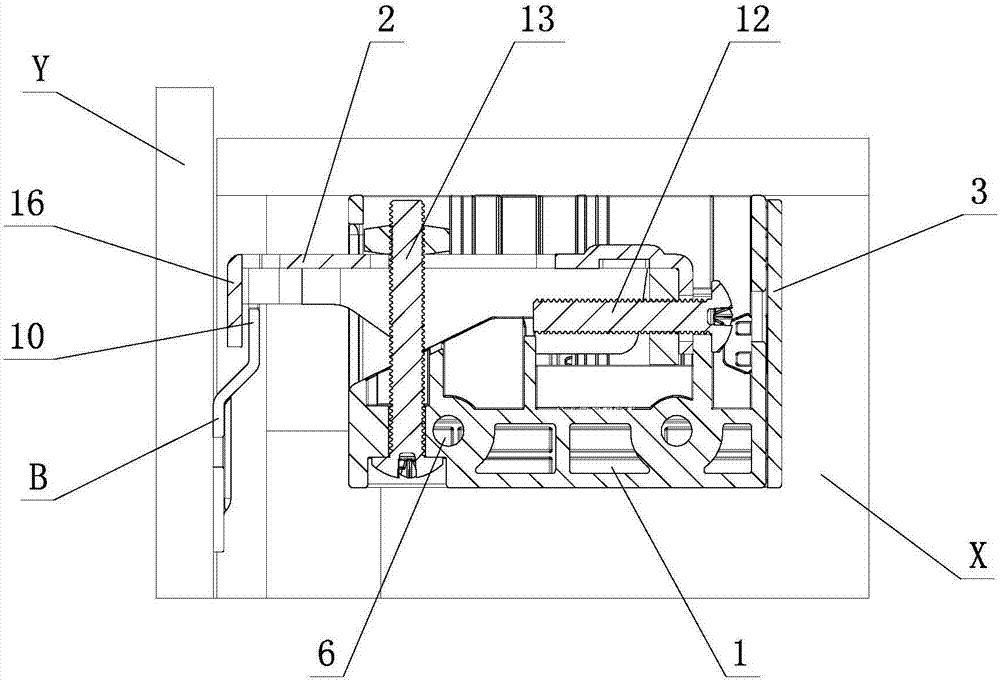

Molding device for bridge-cutting-free heat-insulation aluminum profiles

The invention provides a molding device for bridge-cutting-free heat-insulation aluminum profiles and relates to the fields of manufacturing of the heat-insulation aluminum profiles, machining of aluminum profile doors and windows and the like, aiming at overcoming the problems of an existing heat-insulation aluminum profile manufacturing process that time and labor are wasted, the energy source consumption is great, the manufacturing cost is high and the production efficiency is low since an aluminum alloy connection part needs to be cut off after the curing. The molding device is composed of a rack, a follow fixture, a glue supplying system and a glue injection head; one aluminum profile C with the complicated section is divided into two parts to manufacture two aluminum profiles A and B with the simple sections; then the aluminum profiles A and B are put into the follow fixture; the follow fixture and the glue injection head move relatively; a glue injection nozzle is used for mixing and agitating double-component polyurethane and then pouring the mixture into a pouring groove opening B formed by the aluminum profiles A and B; a polyurethane heat-insulation strip A is formed by curing and molding the double-component polyurethane and the aluminum profiles A and B are connected integrally to achieve connection and heat-insulation effects, so that a bridge cutting procedure can be omitted. With the adoption of the molding device and method provided by the invention, the single-color or double-color bridge-cutting-free heat-insulation aluminum profiles can be machined.

Owner:DALIAN HUAGONG INNOVATION TECH

Liquor anti-counterfeiting system

InactiveCN102799988AReduce manufacturing costReduce high production costsUser identity/authority verificationSensing record carriersComputer moduleEngineering

The invention relates to an anti-counterfeiting system, and particularly relates to an anti-counterfeiting system for distinguishing whether liquor is true or false. A liquor anti-counterfeiting system comprises a container, a card reader, and a call center; the container consists of a bottle body, a bottle cover and a sealing opening; the bottle cover and the sealing opening are integrally pressed on the bottle body; sensing chips are arranged on the bottle cover and the sealing opening; an identity code compiled in a production process is printed on the outer surface of the bottle cover; a verification code matched with the identity code is printed inside the bottle cover; a sensing module is arranged inside the card reader; the card reader sends information provided by the sensing chips to the call center after the sensing chips approach; the call center feeds back the information to the card reader; and the card reader judges whether the liquor is true or false according to the feedback information. The liquor anti-counterfeiting system provided by the invention has a simple realization method, so that the liquor can be verified to be true or false through various means. However, the production cost of a manufacturer is increased rarely. A consumer can verify by using various resources which are suitable for the user to use, so that the anti-counterfeiting system is convenient to use. The rampant adulterated wine manufacturing industry can be effectively attacked, and the liquor anti-counterfeiting system has large social and economical values.

Owner:莫建林

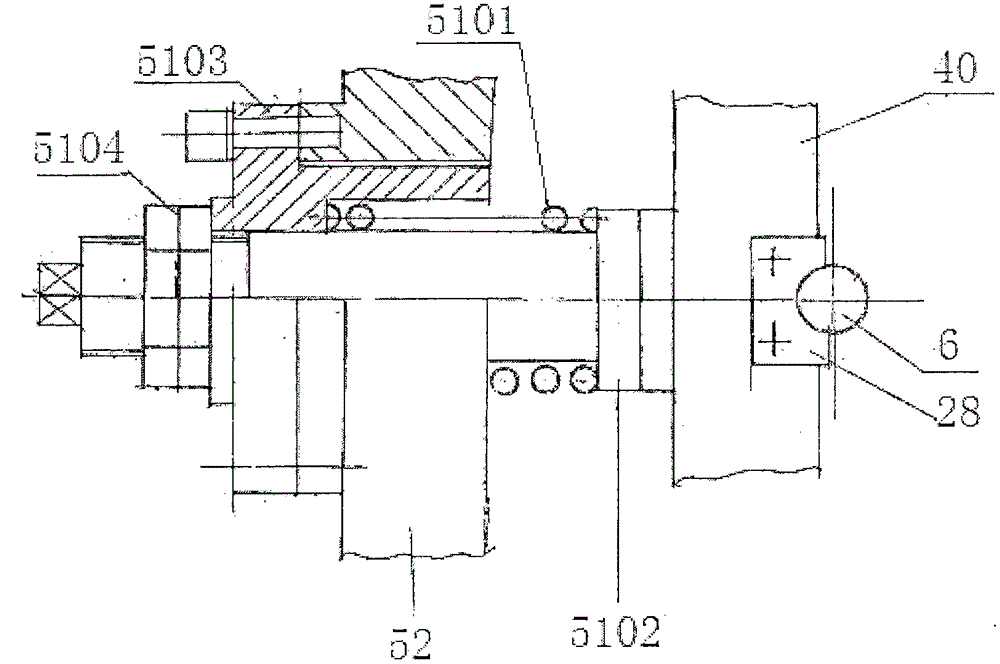

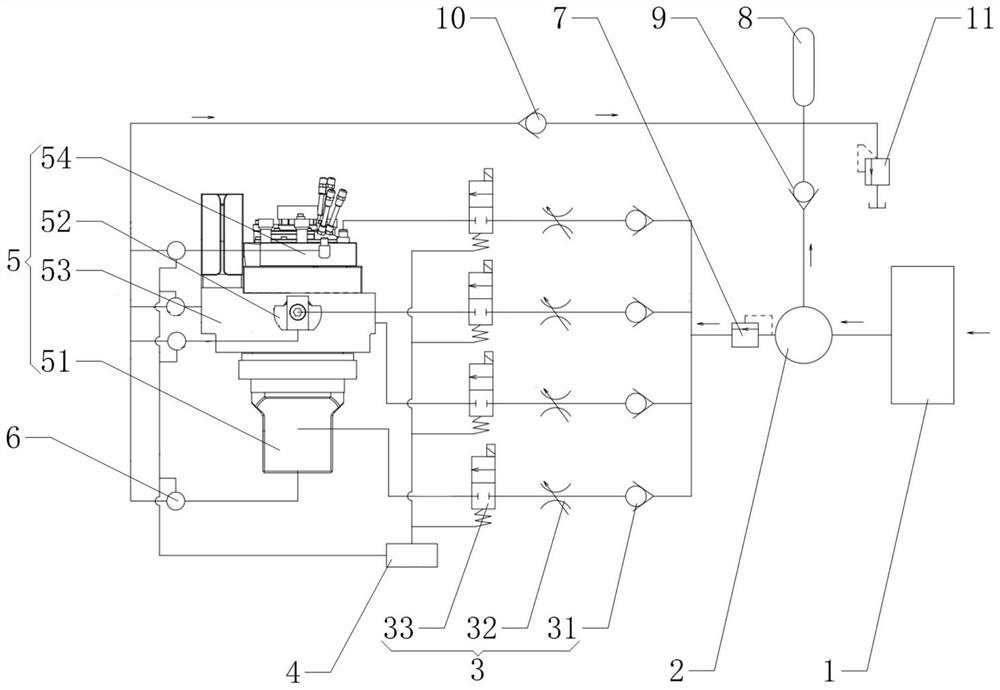

Double-direction precise hydraulic bar shearing machine and shearing method thereof

ActiveCN105345123ASolve the problem of thermal shear power consumptionSolve wasteShearing machinesStress concentrationBar stock

The invention provides a double-direction precise hydraulic bar shearing machine and a shearing method of the machine. At the beginning of shearing, a moon arc notch is cut in the radial left side of a bar, a gap is cut in the hard layer of the radial surface, stress concentration and slight bar lattice slippage are generated, a shear switch issues an order to an oil cylinder immediately, the motion direction is reversed to the leftward movement, a rear cutter shears off the bar along the gap, and for example, when low-carbon steel is shorn, the radial pressure skewness is small, and burrs are few; and if high-carbon alloy steel is shorn, the center portion cannot be torn off. The double-direction precise hydraulic bar shearing machine comprises a sliding block, a front cutter portion, a rear cutter portion, a shear depth adjusting portion and a spring device. The front cutter portion is used for centering and clamping the bar and is mounted on a front lathe, and the front cutter portion comprises a left wedge, a left cutter table, an oil cylinder, a right wedge, a right cutter table, a screw and blades.

Owner:沈阳恒佳忠祥液压设备有限公司

Switch supervision device, control system and control method

ActiveUS8987945B2Reduce high production costsSuppress powerEmergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesMicrocomputerControl system

A control system has an instruction path of which an object section connects a microcomputer, a switch and a switch supervisory device with one another. The switch sets the path in conductive or non-conductive state on the low side of the microcomputer. An instruction signal is sent to the microcomputer through the conductive path to set the microcomputer in an operation state. When the device judges based on the operation state of the microcomputer that the switch has set the path in a conductive state, the device sends a first signal of first voltage, causing the signal to have current strength equal to or higher than predetermined value in the path, to the object section. When the device judges that the switch has set the path in a non-conductive state, the device sends a second signal of second voltage lower than first voltage to the object section.

Owner:DENSO CORP

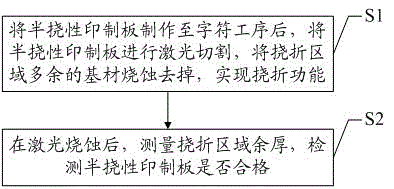

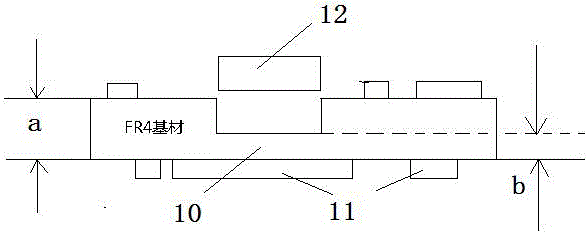

Semi-flexible printed board with rupture function and manufacturing method thereof

ActiveCN106455339AImprove reliabilitySave production processPrinted circuit manufactureLaser ablationManufacturing engineering

The invention discloses a semi-flexible printed board with a rupture function and a manufacturing method thereof. The manufacturing method comprises the following steps of A, manufacturing the semi-flexible printed board to a character procedure, cutting the semi-flexible printed board by laser, and ablating to remove the excessive substrate of a rupture area, so as to realize the rupture function; B, after laser ablation, measuring the allowance thickness of the rupture area, and detecting whether the semi-flexible printed board is qualified or not. The manufacturing method has the advantages that the manufacturing process and time are effectively saved, the efficiency is improved, the high manufacturing cost is effectively reduced, the rupture property and reliability are improved, and the problem of poor reliability of a terminal electronic product due to poor rupture property is solved.

Owner:SHENZHEN KINWONG ELECTRONICS

Automatic film laminating, sealing, cutting and shrinking packaging machine

ActiveCN110949763AReduce high production costsHigh speedWrapping material feeding apparatusShrink wrapFilm-coated tablet

The invention discloses an automatic film laminating, sealing, cutting and shrinking packaging machine, which is provided with a support platform and a film laminating mechanism fixed on a bracket table and rotationally applying a film to a product; a film pressing mechanism fixed on the bracket table and used for tightly pressing and transmitting a film coating the product to a specified position; and a moving assembly disposed adjacent to the film laminating mechanism, and used for clamping and moving the product at the specified position to a predetermined place, and cutting and laminatingthe tail end of the product. A packaging material rotates around the product, which moves forwards at a constant speed, through the film laminating mechanism. Meanwhile, the tension of the packaging material is adjusted through a film clamping mechanism, an object is packaged into a fastened whole, and spiral packaging is formed in the surface of the object. Thus, the number of operators is reduced, the production cost is reduced, and the speed is increased.

Owner:马泽琴 +2

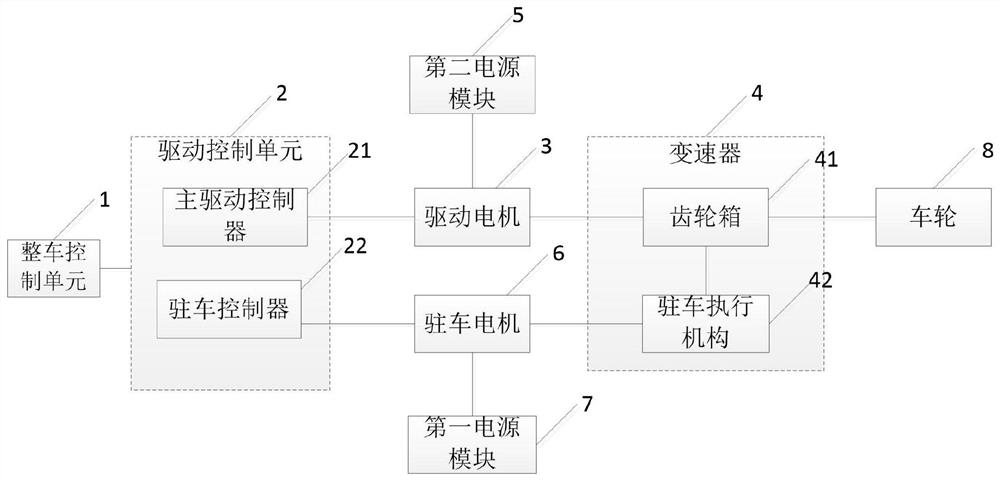

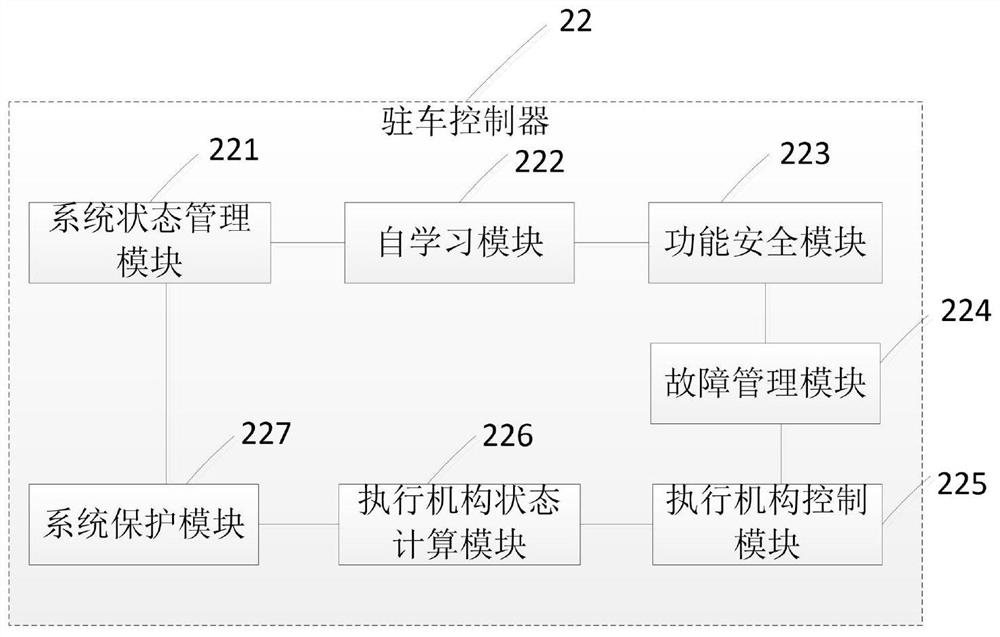

Electronic parking system, vehicle control system and vehicle

PendingCN113043852AReduce the space occupied by the carSimple structureSpeed controllerElectrodynamic brake systemsControl systemControl cell

The invention provides an electronic parking system, a vehicle control system and a vehicle, and is applied to the technical field of electronic parking. According to the electronic parking system provided by the invention, the parking controller in the electronic parking system independent of the electric drive axle of the vehicle in the prior art is integrated in the drive control unit of the electric drive axle; the electric drive axle and the electronic parking system which are independent from each other are integrated into one system in a mode of integrating a parking execution structure of the electronic parking system and a speed changer of the electric drive axle together at the same time, so that the electric drive axle and the electronic parking system which are independent from each other are integrated into one system; an electronic controller and connecting wiring between the electronic controller and other parts do not need to be independently configured for the electronic parking system, so that the space occupied by the electronic parking system in the whole automobile is reduced, the structure of electronic and electric appliances is simplified, and the manufacturing cost is reduced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

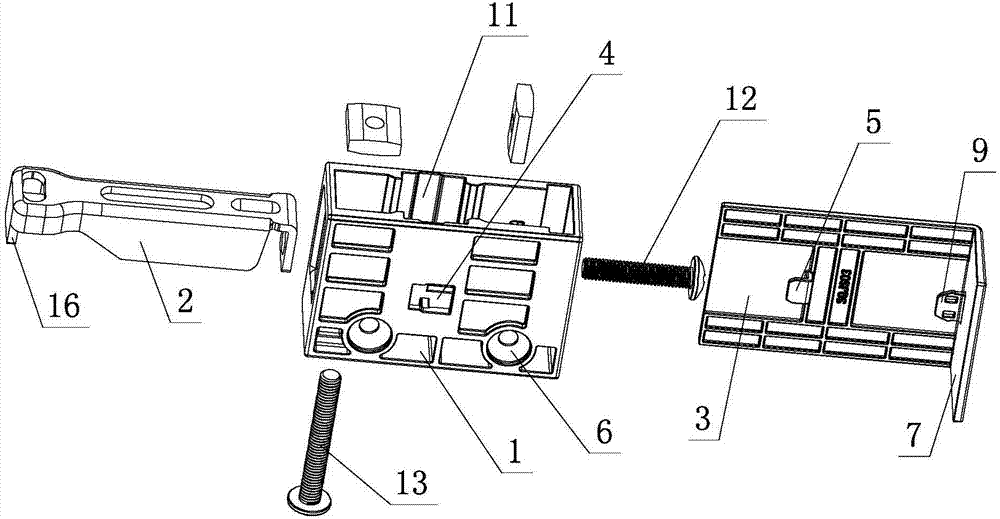

Simple disassembling and assembling structure of furniture cabinet

ActiveCN107467897AEasy to assemble and disassembleReduce high production costsFurniture partsDismountable cabinetsStructural engineeringManufacturing engineering

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Continuous production method of PI film heater and production equipment of PI film heater

InactiveCN107813506ANot easy to produceReduce high production costsOhmic-resistance heatingFlat articlesManufacturing cost reductionElectrical resistance and conductance

The invention relates to a continuous production method of a PI film heater. The continuous production method comprises the following steps that (1), one side of a long roll-shaped heating resistor film is laminated onto a long roll-shaped PI film through a laminating machine, and then vulcanization is carried out through a continuous vulcanizing machine; (2), the heating resistor film on the PI film is manufactured into a heating core through etching; (3), the other side of the heating resistor film manufactured into the heating core in the step (2) is laminated with a PI film through the laminating machine by adopting the same process in the step (1), and then vulcanization is carried out through the continuous vulcanizing machine, thus a semifinished long roll-shaped PI film heater is obtained; and (4), the semifinished long roll-shaped PI film heater manufactured in the step (3) is subjected to size slitting, and the heating core is connected with a lead wire, thus the finished PIfilm heater is obtained. The invention also relates to production equipment of the PI film heater. The continuous production method and the production equipment have the advantages that the probability of bubbles during laminating is low, the product yield can be raised, continuous mass production can be realized, the production efficiency is improved and the manufacturing cost is lowered.

Owner:JIANGYIN HUILONG ELECTRIC HEATING APPLIANCE

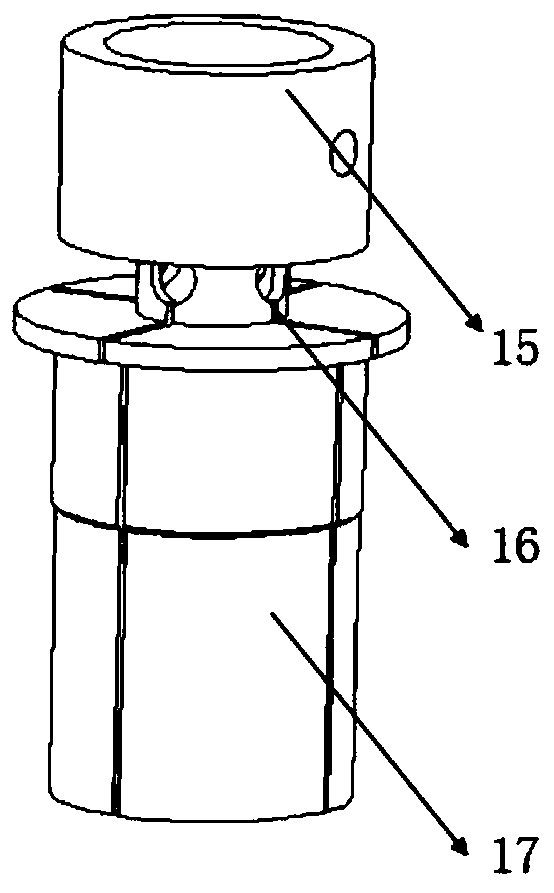

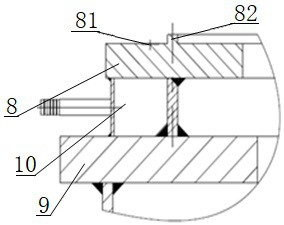

Heterogeneous component clamping device

PendingCN111113302ASolve sheddingSolve the problem that the cylinder is easily damagedWork holdersGrinding work supportsEngineeringMechanical engineering

The invention discloses a heterogeneous component clamping device. The device comprises a mounting frame, a connecting rod, an expansion rod, an expansion sleeve and a driving assembly; the connectingrod is slidably connected with the mounting frame; the expansion sleeve is detachably arranged on the mounting frame and located below the connecting rod; the expansion rod is slidably arranged in the expansion sleeve in a penetrating mode, the upper end of the expansion rod is fixedly connected with the connecting rod, and the lower end of the expansion rod can expand the expansion sleeve so asto clamp heterogeneous components; the expansion rod, the expansion sleeve and the connecting rod are coaxial, and the outer diameter of the connecting rod and the outer diameter of the expansion sleeve are both larger than the diameter of the expansion rod; the expansion rod is sleeved with a spring, one end of the spring is in contact with the connecting rod, and the other end of the spring is in contact with the expansion sleeve; and the driving assembly is fixedly arranged on the mounting frame, and the driving assembly can drive the connecting rod and the expansion rod to move downwards and compress the spring. According to the device, the heterogeneous components can be stably clamped, and the device can be used for clamping various heterogeneous components, so that the problems thatthe heterogeneous components are prone to falling off, an air cylinder is prone to being damaged and the production cost is high are solved.

Owner:XIAMEN UNIV OF TECH

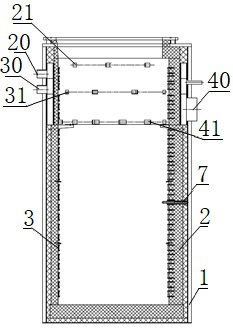

Energy-saving and durable high-efficiency reduction and distillation integrated electric furnace for the production of sponge titanium

ActiveCN111020229BReduce unit energy consumptionImprove the rate of excellent productsInsulation layerProcess engineering

The invention relates to an energy-saving, durable, high-efficiency reduction and distillation integrated electric furnace for the production of sponge titanium. A circle of annular bosses and a circle of annular grooves are set on the outside; an insulation layer is provided on the inner wall of the furnace shell; multiple rows of annular air inlet ducts and one or more rows of annular air outlet channels are arranged in the insulation layer of the upper section of the electric furnace. Multiple air inlets and multiple air outlets are evenly arranged along the circumference from the annular air inlet duct to the electric furnace; the total air inlet pipe of the annular air inlet duct is connected to the frequency conversion fan and the exhaust chimney; the inner side of the furnace insulation layer is respectively equipped with thermocouples The multi-zone resistance heating wire or belt of the temperature measuring device; a plurality of inward anti-collision columns in the circumferential direction are arranged in the middle and lower part of the inner circumference of the electric furnace shell; It has the advantages of reducing energy consumption, improving production efficiency, prolonging life, reducing high production costs, and increasing the rate of high-quality sponge titanium.

Owner:新疆湘润新材料科技有限公司

Automatic suspender

InactiveCN103332588BIncrease flexibilityAccurate spacing controlLoad-engaging elementsWork productivityEconomic shortage

The invention discloses an automatic suspender. The suspender comprises a suspension arm and at least a suspension hook. The suspender is characterized in that at least one suspension hook is movably arranged on the suspension arm. The invention provides an automatic suspender. The suspender realizes automatic article lifting, overcomes the shortages of low efficiency, high production cost, large workload, high work strength, and high danger for a person in a handling zone, which are caused by human operation of a conventional suspender, improves work efficiency, and reduces production cost and work strength of workers.

Owner:上海敏坚实业有限公司

Energy-saving durable efficient reduction-distillation integrated electric furnace for titanium sponge production

The invention relates to an energy-saving durable efficient reduction distillation integrated electric furnace for titanium sponge production. The electric furnace comprises a steel electric furnace shell, a forced circulation cooling water jacket is arranged between an upper flange and a lower flange on the upper part of the furnace shell, a ring of annular boss is arranged on the upper flange, and a ring of annular groove is arranged outside the upper flange; an insulating layer is arranged on the inner wall of the furnace shell; a plurality of rows of annular air inlet channels and one or more rows of annular air outlet channels are arranged in the heat insulation layer of the upper section of the electric furnace, and a plurality of air inlets and a plurality of air outlets are uniformly arranged from the annular air inlet channels in the heat insulation layer to interior of the electric furnace along the circumference; a total air inlet pipe of the annular air inlet channels is connected with a frequency conversion fan and an exhaust chimney; a multi-zone resistance heating wire or belt respectively provided with a thermocouple temperature measuring device is arranged on the inner side of the heat insulation layer in the furnace; a plurality of inward anti-collision columns in the circumferential direction are arranged at the middle lower part of the inner circumference ofthe furnace shell of the electric furnace; and a ring of annular wind deflector is arranged on the lower edges of the annular wind outlet channels. The electric furnace has the advantages that the energy consumption is reduced, the production efficiency is improved, the service life is prolonged, the production cost is reduced, and the excellent product rate of the titanium sponge is improved.

Owner:新疆湘润新材料科技有限公司

Automatic film sealing and cutting shrink packaging machine

ActiveCN110949763BReduce high production costsHigh speedWrapping material feeding apparatusShrink wrapFilm-coated tablet

The invention discloses an automatic film laminating, sealing, cutting and shrinking packaging machine, which is provided with a support platform and a film laminating mechanism fixed on a bracket table and rotationally applying a film to a product; a film pressing mechanism fixed on the bracket table and used for tightly pressing and transmitting a film coating the product to a specified position; and a moving assembly disposed adjacent to the film laminating mechanism, and used for clamping and moving the product at the specified position to a predetermined place, and cutting and laminatingthe tail end of the product. A packaging material rotates around the product, which moves forwards at a constant speed, through the film laminating mechanism. Meanwhile, the tension of the packaging material is adjusted through a film clamping mechanism, an object is packaged into a fastened whole, and spiral packaging is formed in the surface of the object. Thus, the number of operators is reduced, the production cost is reduced, and the speed is increased.

Owner:马泽琴 +2

Interactive mobile television system applied to mobile terminal device and method thereof

InactiveCN101888532BFast updateLow costBroadcast service distributionSelective content distributionChat roomInteractive television

The invention discloses an interactive mobile television system applied to a mobile terminal device and a method thereof. The interactive mobile television system comprises a mobile client device, a mobile user authentication unit, a charge unit, a user uploaded program editing unit, a user uploaded data editing unit, a media company program content unit, a broadcast content synthesizing unit anda broadcast transmission unit. The invention provides an active mobile television system which is actively participated by audiences, applied to mobile television communities, provided with value-added services, mainly applied to the mobile terminal device and provided with interactive multi-media services; and furthermore, the interactive mobile television service is further integrated with a mobile chat room to provide relevant application in the aspect of the communities, and provides an interactive platform for the audiences who watch the same program by combining the mobile television service with the mobile chat room.

Owner:CHUNGHWA TELECOM CO LTD

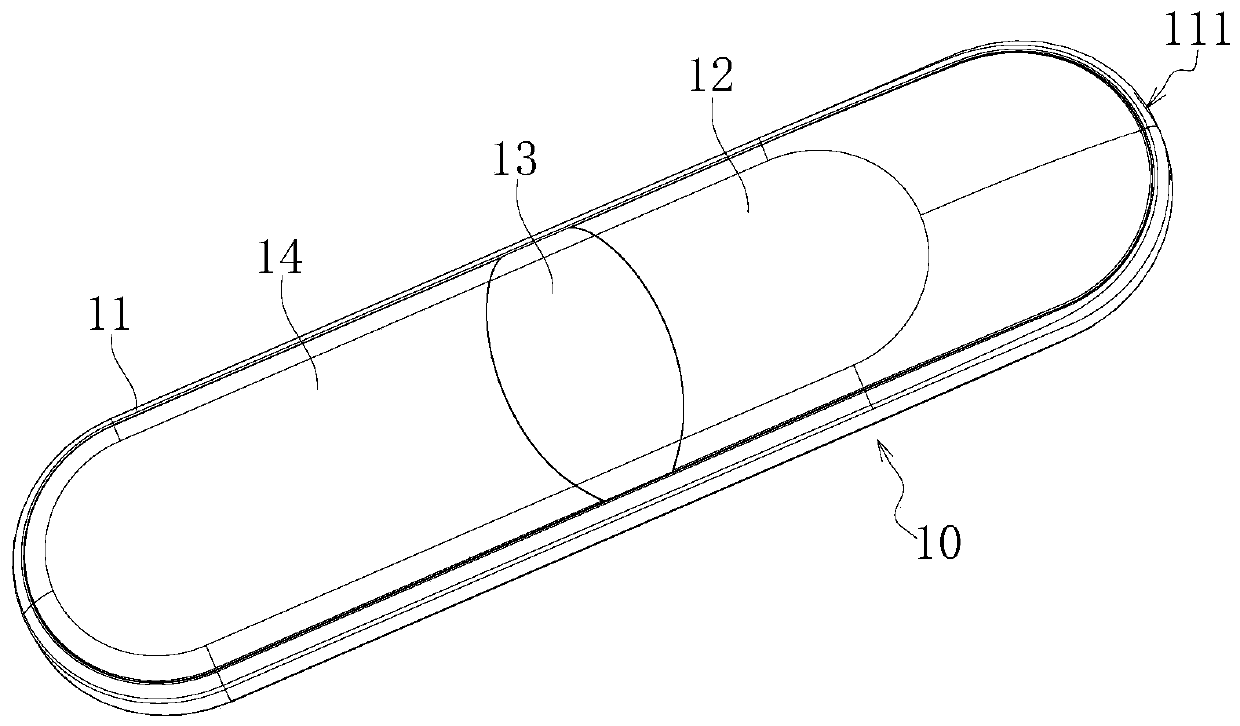

Electronic cigarette shell and disposable electronic cigarette

PendingCN110367600AIncrease productivityReduce high production costsTobacco devicesElectronic cigaretteSmoke

The invention belongs to the technical field of electronic cigarettes, and particularly relates to an electronic cigarette shell and a disposable electronic cigarette. The electronic cigarette shell comprises a bottom shell, a front shell, a middle shell and a back shell, wherein a mounting cavity with an opening is formed on one side of the bottom shell; the front shell, the middle shell and theback shell are arranged in the mounting cavity in sequence, and the opening is sealed; the front end of the bottom shell is provided with a smoking hole; the front end of the front shell is provided with a smoke outlet which communicates with the smoking hole; and an air inlet gap is formed at the joint between the bottom shell and at least one of the front shell, the middle shell and the back shell. The shell is of a three-segment design, and the air inlet and air outlet are formed by the air inlet gap formed at the joint between the bottom shell and at least one of the front shell, the middle shell and the back shell as well as the smoking hole formed at the front end of the bottom shell and the smoke outlet formed at the front end of the front shell, so that the whole shell structure issimplified; the assembly of the shell and the assembly of other components which can be arranged inside the shell become easier; the production efficiency of the electronic cigarette is improved; andthe production cost is lowered.

Owner:中健天和(北京)科技发展有限公司

A two-way precision hydraulic bar shearing machine and its shearing method

ActiveCN105345123BSolve the problem of thermal shear power consumptionSolve wasteShearing machinesStress concentrationEngineering

The invention provides a double-direction precise hydraulic bar shearing machine and a shearing method of the machine. At the beginning of shearing, a moon arc notch is cut in the radial left side of a bar, a gap is cut in the hard layer of the radial surface, stress concentration and slight bar lattice slippage are generated, a shear switch issues an order to an oil cylinder immediately, the motion direction is reversed to the leftward movement, a rear cutter shears off the bar along the gap, and for example, when low-carbon steel is shorn, the radial pressure skewness is small, and burrs are few; and if high-carbon alloy steel is shorn, the center portion cannot be torn off. The double-direction precise hydraulic bar shearing machine comprises a sliding block, a front cutter portion, a rear cutter portion, a shear depth adjusting portion and a spring device. The front cutter portion is used for centering and clamping the bar and is mounted on a front lathe, and the front cutter portion comprises a left wedge, a left cutter table, an oil cylinder, a right wedge, a right cutter table, a screw and blades.

Owner:沈阳恒佳忠祥液压设备有限公司

Piston casting mold cooling system and piston casting equipment

The invention discloses a piston casting mold cooling system which comprises an air compressor, a vortex tube, a control valve bank and a controller, an output port of the air compressor is communicated with a gas inlet of the vortex tube, a low-temperature gas outlet of the vortex tube is connected with a gas inlet of the control valve bank, and a gas outlet of the control valve bank is connected with a cooling flow channel inlet of a casting mold. The controller is in communication connection with the control valve set so as to control low-temperature compressed gas generated by the vortex tube to enter a cooling flow channel of the casting mold. And the cooling speed is increased, and then the piston blank head metallographic structure grade is improved. Corrosion and leakage of cooling water to the mold are effectively avoided, the production efficiency is improved, the manufacturing cost is reduced, the overall performance is improved, compressed gas can be reused, and the workshop production cost is saved to a certain extent. The invention further discloses piston casting equipment comprising the piston casting mold cooling system.

Owner:湖南江滨机器(集团)有限责任公司

Fuse box mounting structure

InactiveCN108615663AReduce design requirementsGuaranteed structural strengthEmergency protective devicesMechanical engineeringEngineering

The invention discloses a fuse box mounting structure which comprises a fuse box and an instrument panel main pipe beam. At least two side surfaces of the instrument panel main pipe beam and the fusebox are respectively provided with a buckle. The instrument panel main beam is provided with a first mounting bracket and a second mounting bracket. The outer end of the first mounting bracket and theouter end of the second mounting bracket are respectively provided with a buckle seat. The buckle seat is provided with a buckle hole. The buckle is in snapping matching with the buckle hole. The invention aims to provide the fuse box mounting structure which reduces a designing requirement and facilitates assembling.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com