Heat pump rectification process used for C4 separation

A technology of heat pump rectification and process, which is applied in the direction of distillation purification/separation, hydrocarbon purification/separation, chemical industry, etc. It can solve the problems of increasing energy consumption of compressors and deterioration of energy saving effect, and achieves low energy consumption and lower temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

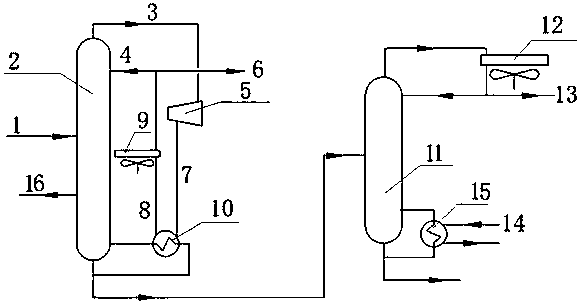

[0012] As shown in the figure, a heat pump rectification process for C4 separation, feed 1 passes through two series-connected rectification towers to complete the separation of isobutane, n-butane and C5 heavy components, isobutane n-butane The mixture is fed from the front rectification tower 2, and isobutane is extracted from the top of the front rectification tower 2, and the front rectification tower is extracted from the front rectification tower. Alkanes and carbon 5 heavy components. The composition ratio of n-butane and carbon 5 heavy components in the bottom of the front rectification tower is 5:1~2:1. The bottom of the front rectification tower is taken out and enters the rear rectification tower. The remaining n-butane is extracted from the top of the distillation tower, and the carbon 5 heavy component is extracted from the bottom of the rear rectification tower. Distillation tower reboiler 10 is used as a heat source to heat the tower still material, obtains cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com