Flame-retarding polyurethane sealing material for coal mine

A polyurethane and mine technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of poor airtightness, high time and physical consumption, unsatisfactory flame retardant performance, etc., and achieve light weight, reduced construction period, and flame retardant effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

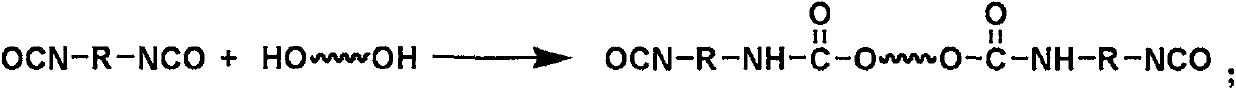

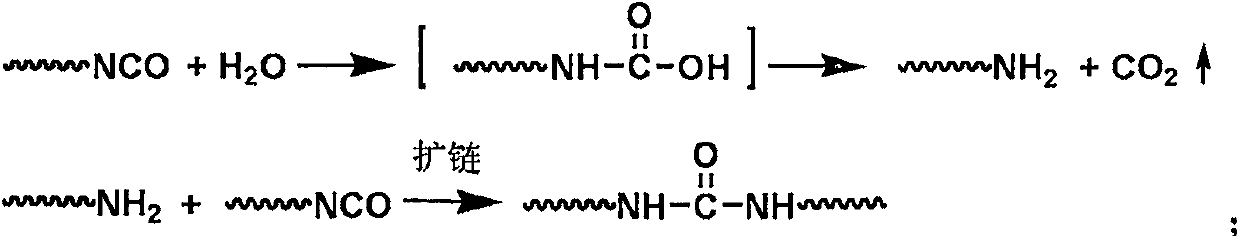

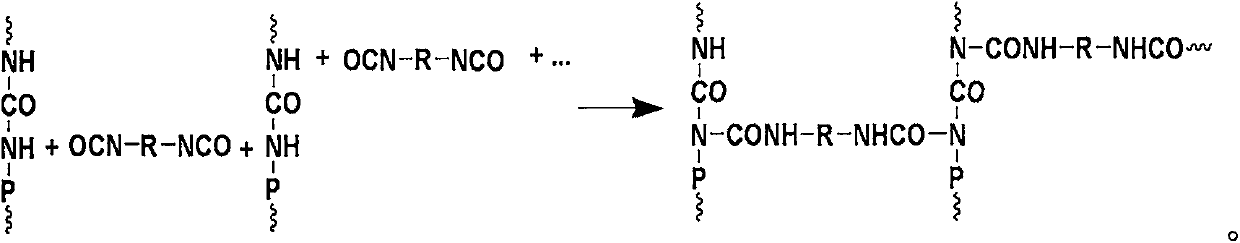

Method used

Image

Examples

Embodiment

[0021] Embodiments, sample the isocyanate, polyether polyol, simethicone, expandable graphite and sodium silicate in Examples 1 to 21 according to the weight parts of the corresponding raw materials in the following table, and propose according to the present invention respectively The preparation method of the polyurethane sealing material according to the present invention is to prepare the polyurethane sealing material, and the specific operations are as follows: Weigh the polyether polyol of the corresponding weight part and place it in the reaction bottle, and then add the corresponding weight parts of simethicone, expandable graphite, Sodium silicate and isocyanate are stirred evenly at a speed of 150-400r / min, the stirring time is controlled at 10-30min, and the polyurethane sealing material is obtained after standing still until complete foaming. Then the performance test of the prepared polyurethane sealing material was carried out.

[0022]

[0023]

[0024] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com