Control device based on flexible triggering of silicon controlled rectifier

A control device, a sensitive technology, applied in flow control, non-electric variable control, control/regulation system, etc., can solve problems such as inability to increase humidity, influence of staff, poor impurity removal effect, etc., to achieve fast reactive power change, The effect of quick switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

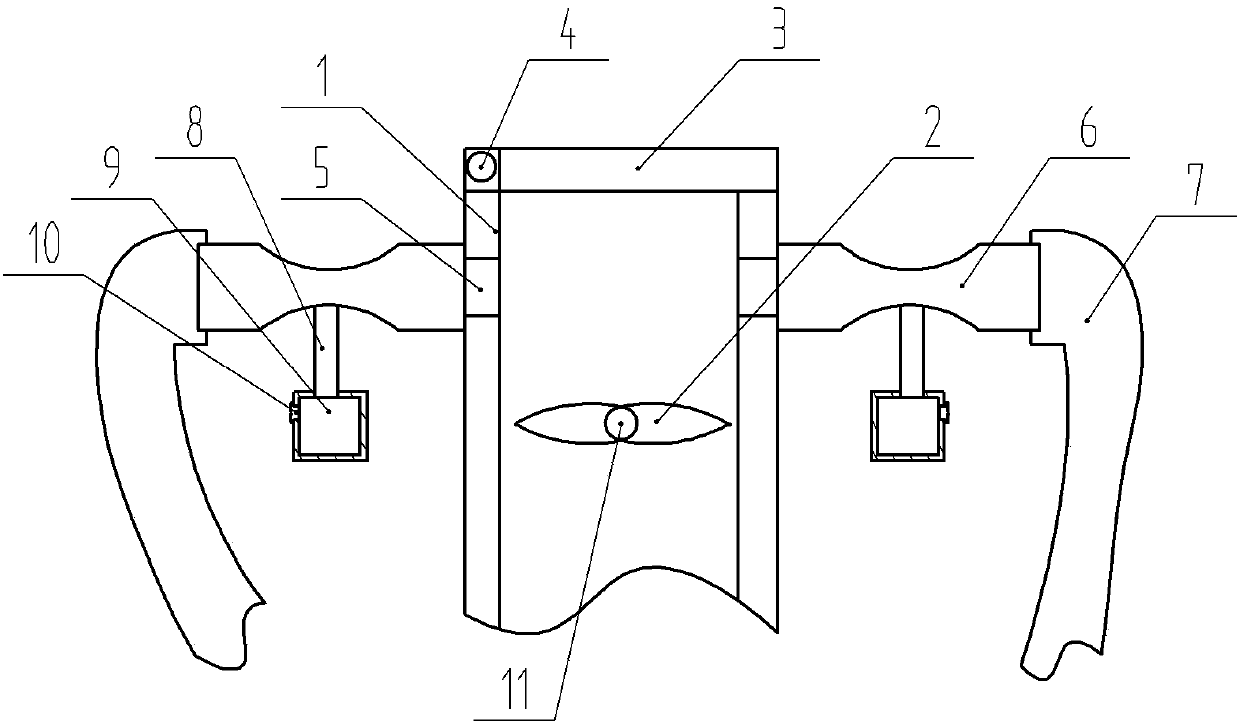

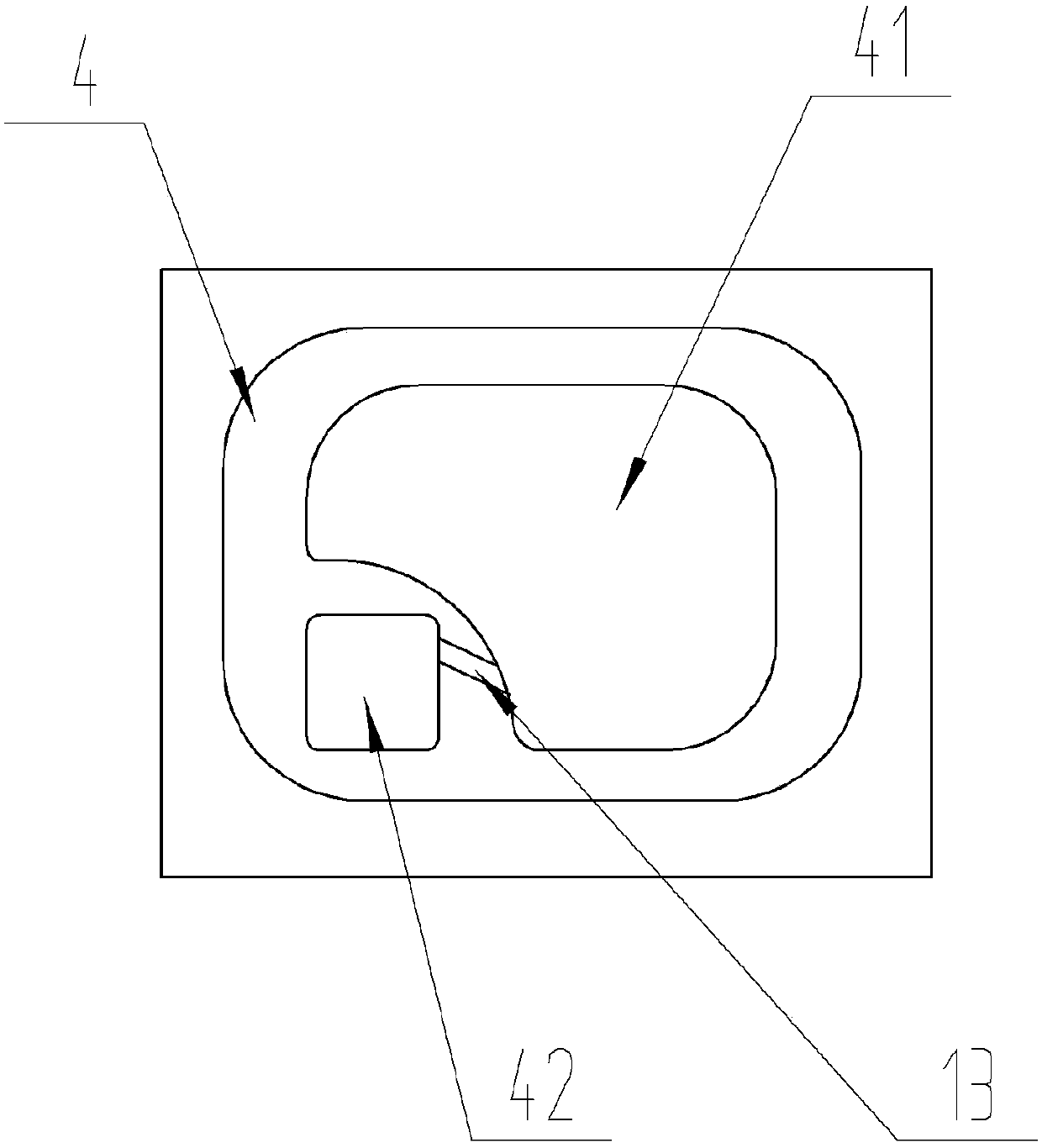

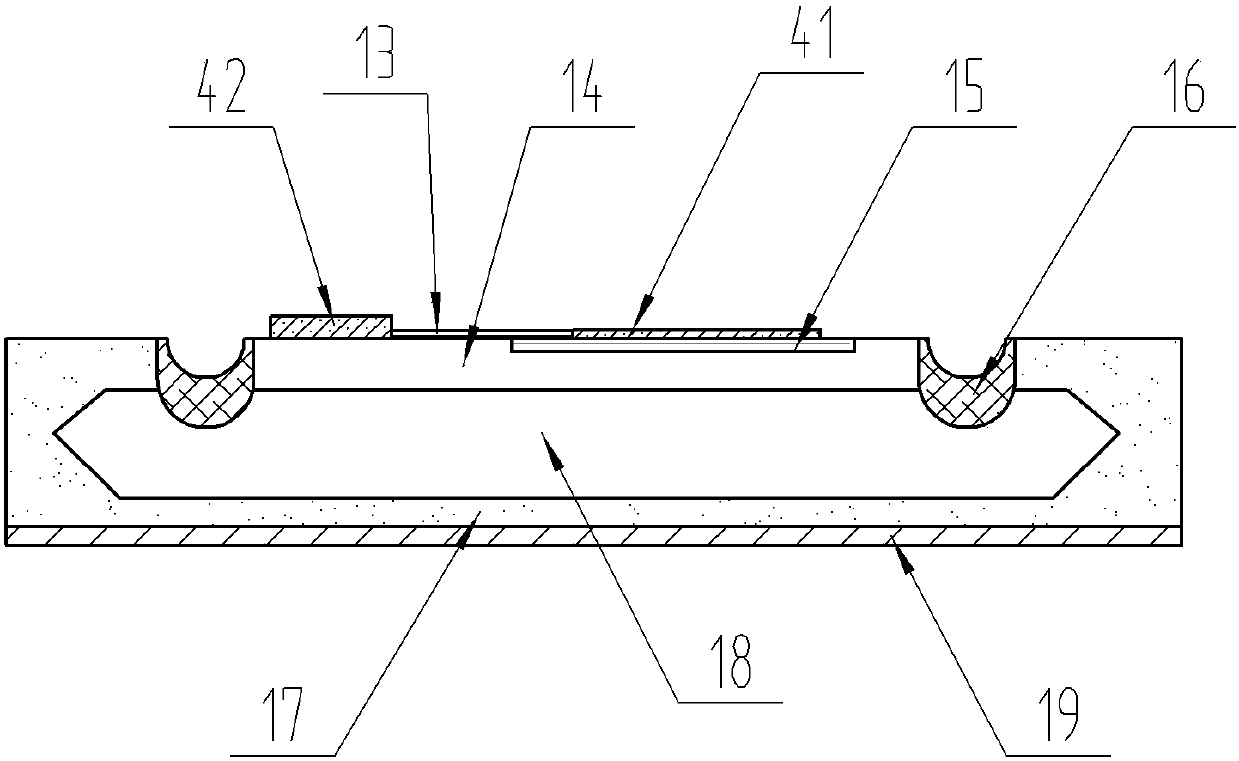

[0021] The reference signs in the drawings of the specification include: flue pipe 1, fan blade 2, solenoid valve 3, thyristor 4, cathode electrode K41, gate electrode G42, through hole 5, Venturi tube 6, hose 7, Water pipe 8, water tank 9, cork 10, rotating shaft 11, resistance 13, P-type short base area 14, N+ type emission area 15, glass passivation 16, P-type anode area 17, N-type long base area 18, anode electrode A19.

[0022] Such as figure 1 As shown, the control device based on the sensitive trigger silicon controlled rectifier in this embodiment includes a flue pipe 1, the flue pipe 1 is provided with a rotating shaft 11, one end of the rotating shaft 11 is fixedly connected to the output shaft of the motor, and the rotating shaft 11 is There is a fan blade 2 fixed on one end. When the motor is started, the motor drives the rotating shaft 11 to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com