High-efficiency Needle Transfer Technology for Diodes

A diode and high-efficiency technology, applied in the field of diodes, can solve problems affecting flexibility and production efficiency, diode electrical instability, waste of raw material usage, etc., to achieve the effects of improving efficiency, saving labor costs, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail now:

[0023] A high-efficiency needle-transfer mounting process for diodes, comprising:

[0024] (1) The steps of making the upper and lower frames of the patch diode and closing the mold;

[0025] (2) Welding steps;

[0026] (3) Steps of plastic sealing;

[0027] (4) steps of curing and electroplating;

[0028] (5) Steps of cutting ribs, bending and forming;

[0029] (6) Steps of reflow soldering;

[0030] (7) Steps of inspection and shipment;

[0031] Wherein, the step (1) includes: racking → crystal grain loading into the lower tablet → sieve sheet → tablet loading into the lower frame → crystal grain loading into the upper tablet → sieve sheet → tablet loading into the upper frame → upper and lower frame mold clamping, In racking, each matrix frame is racked;

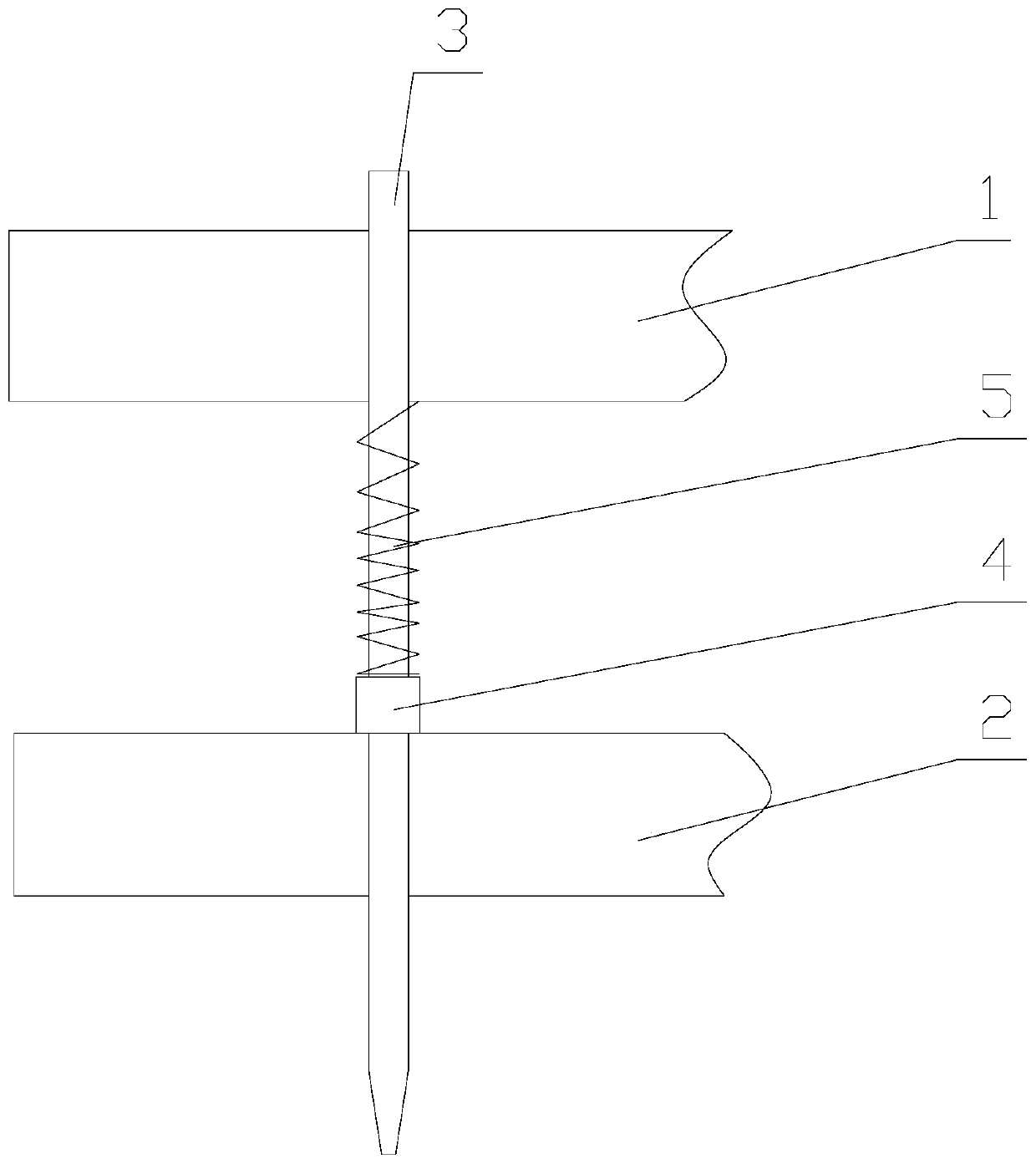

[0032] Wherein, when filling in the step (1), the needle transfer needles using viscose include steel needles 3, upper plate 1, lower plate 2 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com