Method for guiding a crack in the peripheral region of a donor substrate

A substrate and donor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, fine working devices, etc., can solve problems such as edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

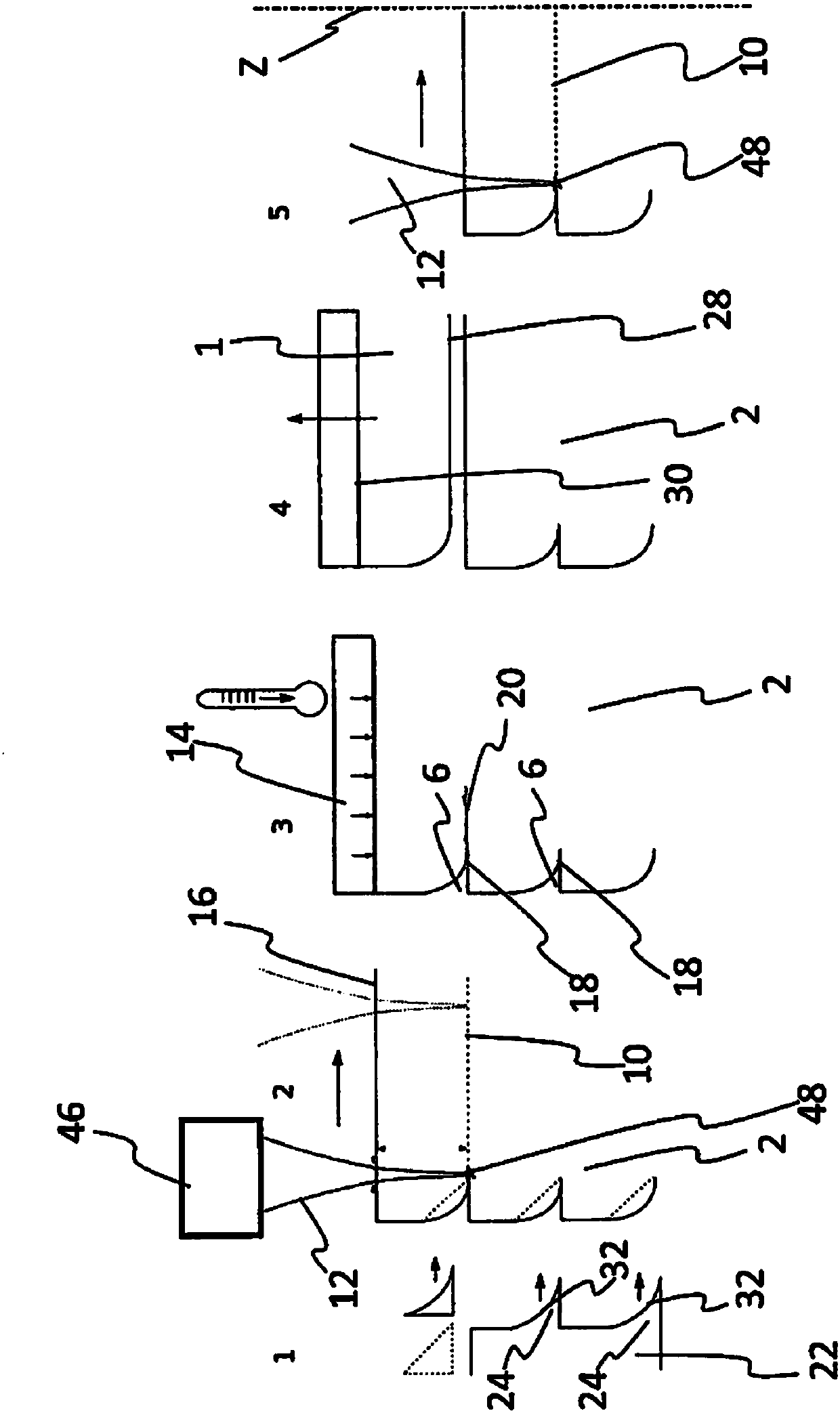

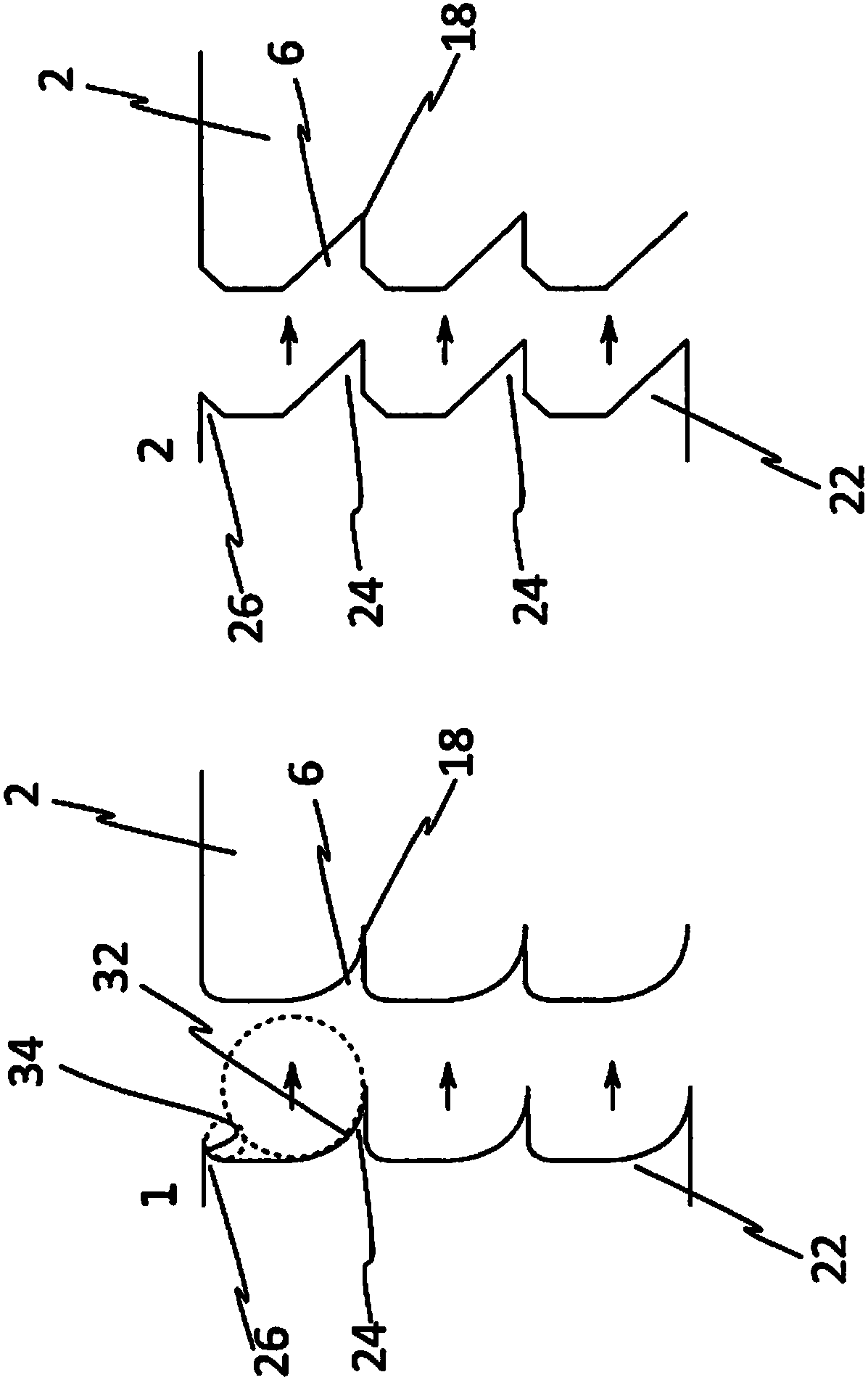

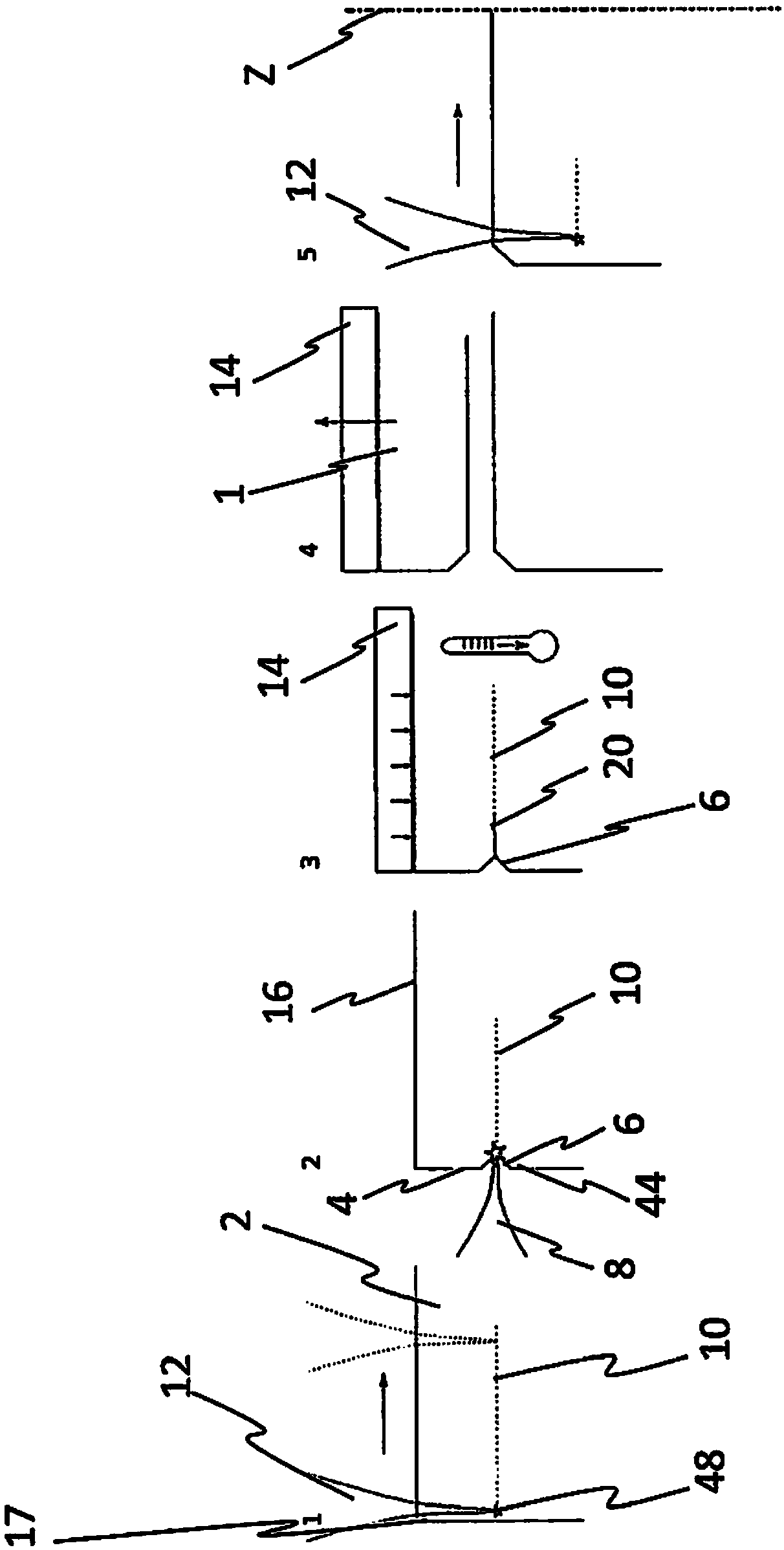

[0048] figure 1 Shown are 5 views by which an example of solid sheet fabrication or wafer fabrication according to the invention is shown. See figure 1 A grinding tool 22 is shown here, which has two machining parts 24 spaced apart from one another, which each form a main grinding surface 32 . The main grinding surface 32 is designed in such a way that it produces a recess 6 in the donor substrate 2 . The grinding tool 22 is preferably designed as a rotary grinding tool or as a belt grinding tool.

[0049] figure 1 view of figure 2 A donor substrate 2 is shown in which a recess 6 has been produced by means of a grinding tool 22 . In this case, the recesses 6 are preferably evenly spaced apart from one another in the longitudinal direction of the donor wafer 2 , wherein it is also conceivable for the distances to be of different sizes. according to figure 2 In the second view in FIG. 1 , modification 10 is also produced in donor substrate 2 by means of laser device 46 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com