Valsartan and amlodipine tablet and preparation method thereof

A technology of valsartan and amlodipine tablets and tablet cores, which is applied in the field of medicine, can solve the problems that the drug dissolution rate and uniformity are difficult to meet the requirements, the content of valsartan and amlodipine is very different, and it is difficult to mix uniformly with excipients, etc. Achieve the effects of increasing drug dissolution, improving water solubility and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

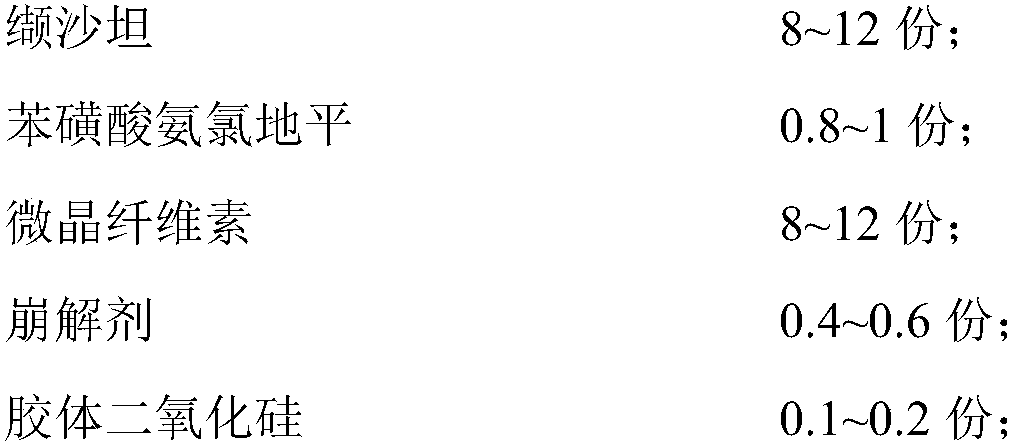

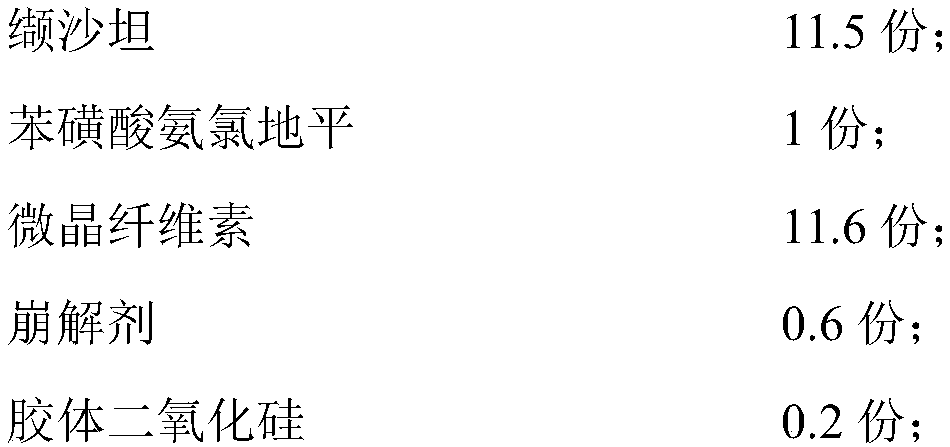

[0040] A kind of valsartan amlodipine tablet, its composition and the content of each composition are as shown in table 1 below. Its preparation method is as follows:

[0041] (1) mixing and pulverizing valsartan and colloidal silicon dioxide to obtain micronized valsartan;

[0042] (2) Amlodipine besylate and microcrystalline cellulose PH103 are uniformly mixed by equal increment method to obtain premix 1;

[0043] (3) Mix the micronized valsartan and crospovidone XL-10 (internal addition) obtained in step (1) with the premix 1 obtained in step (2) and put them into a dry granulator to prepare Get the core;

[0044] (4) The tablet core prepared in step (3), crospovidone XL (additional), magnesium stearate and colloidal silicon dioxide (additional) are mixed evenly, and valsartan amlodipine is obtained after tableting piece.

[0045] The equal increasing method in step (2) is to firstly mix 6.94mg amlodipine besylate and 6.94mg microcrystalline cellulose PH103 to obtain 13...

Embodiment 2

[0081] A valsartan amlodipine tablet, the preparation method of which is the same as that of Example 1, except that the amount of disintegrant is different, see Table 4 below for specific differences.

Embodiment 3

[0094] A kind of valsartan amlodipine tablet, its component and the content of each component are as shown in Table 6 below. Its preparation method is as follows:

[0095] (1) Mixing and pulverizing valsartan and colloidal silicon dioxide to obtain micronized valsartan; wherein, the D50 of micronized valsartan is 3.0 μm, and the D90 is 9.0 μm;

[0096] (2) Amlodipine besylate and microcrystalline cellulose PH103 are uniformly mixed by equal increment method to obtain premix 1;

[0097] (3) Mix the micronized valsartan and crospovidone XL-10 (internal addition) obtained in step (1) with the premix 1 obtained in step (2) and put them into a dry granulator to prepare Get the core;

[0098] (4) Manually mix the tablet core prepared in step (3), crospovidone XL (additional), magnesium stearate and colloidal silicon dioxide (additional), take a sample for detection, calculate the weight of the tablet, and press the tablet Obtain valsartan amlodipine tablet afterward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com