MVR (Mechanical Vapor Recompression) evaporator and application of MVR evaporator in heat transfer system

An evaporator and secondary steam technology, which is applied in the system field of MVR evaporator heat transfer research, can solve the problems of difficulty in handling concentrated liquid, complex landfill leachate composition, and difficulty in efficient and lasting operation of the MVR evaporation system. Less, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

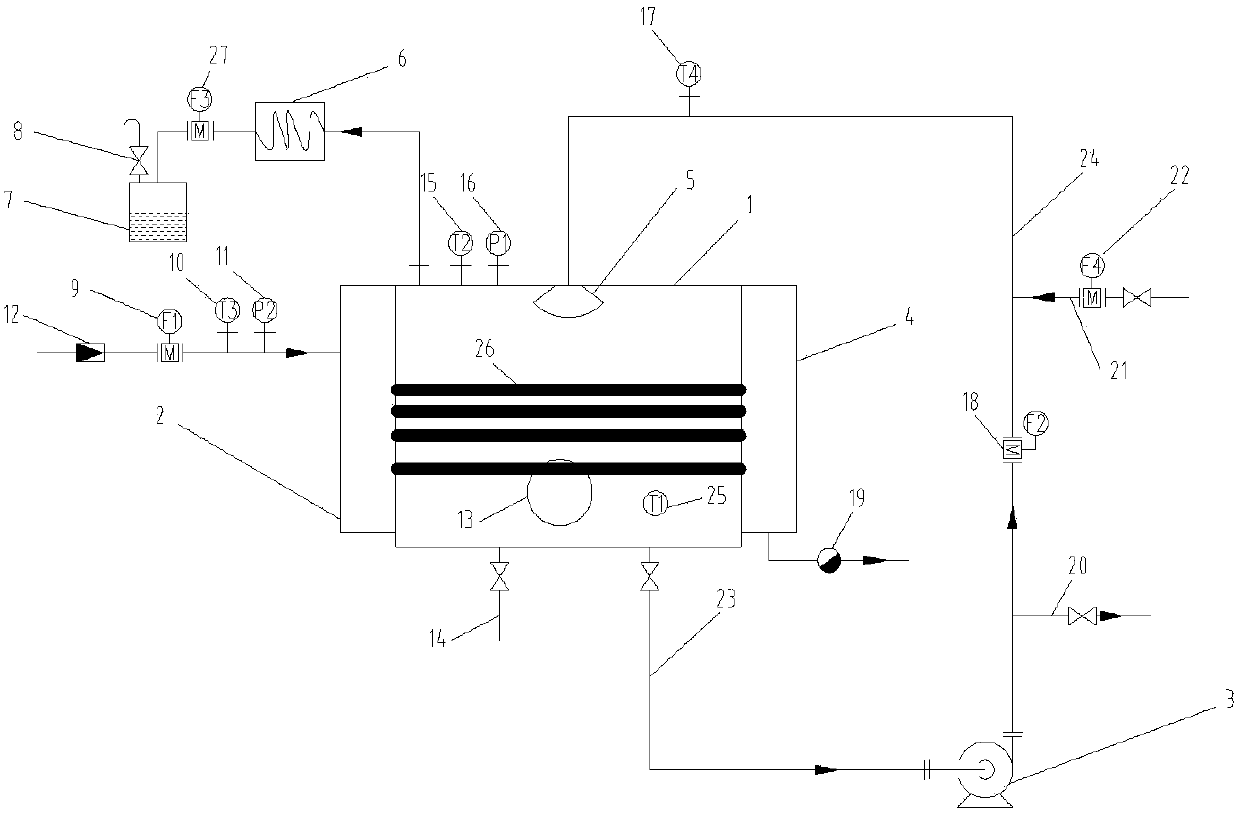

[0019] See attached figure 1 The evaporator body 1 is a cylindrical structure, and the two ends of the cylinder are welded and sealed with two steel plates with round holes. The heat exchange tube 26 is placed in the evaporator through the round holes of the steel plate and sealed with the cylinder through an O-shaped silica gel pad. Heat preservation measures are taken on the outer surface of the cylinder to reduce heat dissipation of the system. The nozzle selected by the liquid distributor 5 ensures that the heat exchange tube 26 distributes the liquid evenly. The steam distributor 2 and the condensed water collector 4 are located at both ends of the cylinder. The pipe 26 is sealed, the frequency conversion circulating pump 3 is located on the ground next to the evaporator, the bottom of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com