Filtering-type air drier

An air dryer and filter drying technology, which is applied in the direction of dispersed particle filtration, gas treatment, membrane technology, etc., can solve the problems of short service life, high power consumption, and high energy consumption, so as to improve service life and cleanliness degree, drying effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

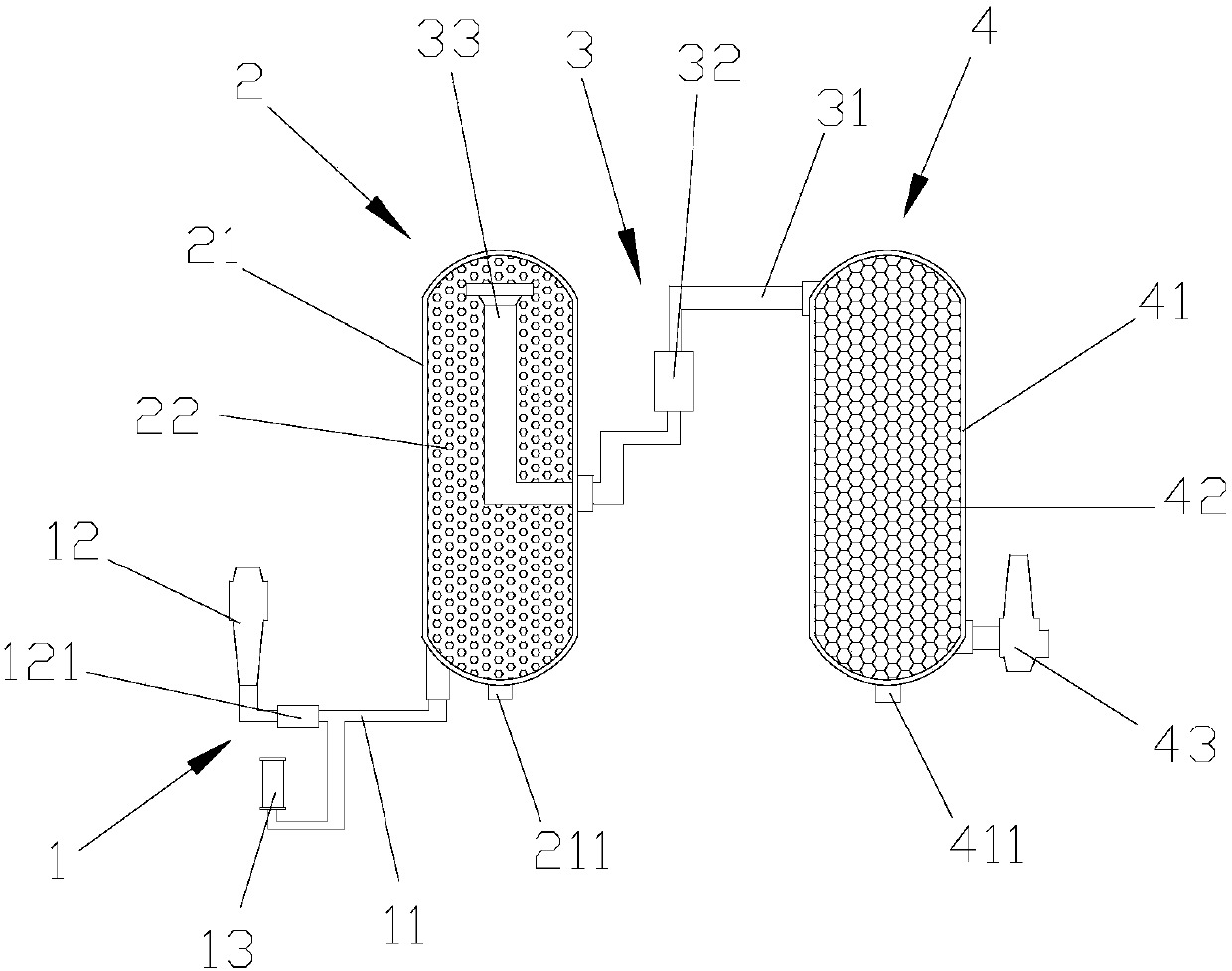

[0029] A filter-type air dryer, such as figure 1 As shown, it includes an air intake device 1, and a first drying tank 2 arranged on one side of the air intake device 1 and communicated with the air intake device 1 for filtering and drying the air, and a first drying tank 2 arranged on the first drying tank 2 on one side and communicated with the first drying tank 2, a communication device 3 for conveying air, and a second drying tank 4 arranged on the side of the communication device 3 for filtering and drying the air; The air intake device 1 includes a pipe body 11, an air inlet 12 arranged at the head end of the pipe body 11 and fixed with the pipe body 11 by welding, and an air inlet 12 arranged in the middle of the pipe body 11 and fixed with the pipe body 11 by screwing. The connected muffler 13 can reduce the noise generated when the air is input, and the lower end of the air inlet 12 is provided with a valve 121 for controlling the air entering. In this embodiment, th...

Embodiment 2

[0042] A filter-type air dryer, such as figure 1 As shown, it includes an air intake device 1, and a first drying tank 2 arranged on one side of the air intake device 1 and communicated with the air intake device 1 for filtering and drying the air, and a first drying tank 2 arranged on the first drying tank 2 on one side and communicated with the first drying tank 2, a communication device 3 for conveying air, and a second drying tank 4 arranged on the side of the communication device 3 for filtering and drying the air; The air intake device 1 includes a pipe body 11, an air inlet 12 arranged at the head end of the pipe body 11 and fixed with the pipe body 11 by welding, and an air inlet 12 arranged in the middle of the pipe body 11 and fixed with the pipe body 11 by screwing. The connected muffler 13 can reduce the noise generated when the air is input, and the lower end of the air inlet 12 is provided with a valve 121 for controlling the air entering. In this embodiment, th...

Embodiment 3

[0055] A filter-type air dryer, such as figure 1 As shown, it includes an air intake device 1, and a first drying tank 2 arranged on one side of the air intake device 1 and communicated with the air intake device 1 for filtering and drying the air, and a first drying tank 2 arranged on the first drying tank 2 on one side and communicated with the first drying tank 2, a communication device 3 for conveying air, and a second drying tank 4 arranged on the side of the communication device 3 for filtering and drying the air; The air intake device 1 includes a pipe body 11, an air inlet 12 arranged at the head end of the pipe body 11 and fixed with the pipe body 11 by welding, and an air inlet 12 arranged in the middle of the pipe body 11 and fixed with the pipe body 11 by screwing. The connected muffler 13 can reduce the noise generated when the air is input, and the lower end of the air inlet 12 is provided with a valve 121 for controlling the air entering. In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com