Corrosion-resistant plastic rope and production process thereof

An anti-corrosion and anti-corrosion agent technology, applied in the field of plastic ropes, can solve the problems of reduced tensile strength and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is a corrosion-resistant plastic rope, comprising the following steps:

[0052] S1: 70 parts of modified polyethylene, 15 parts of plant cellulose fibers, 16 parts of plasticizer, 1 part of foaming agent, 2 parts of corrosion inhibitor and 1 part of dispersant are mixed to obtain a blend;

[0053] Wherein the preparation process of modified polyethylene is as follows:

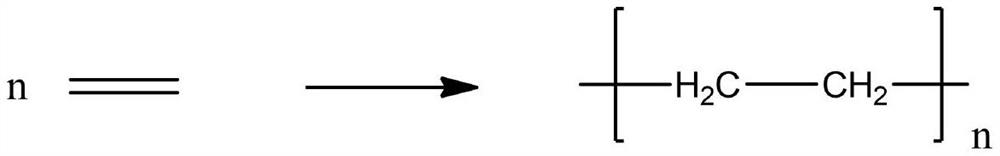

[0054] S21: Add ethylene to the reactor, add catalyst, control the pressure at 0.1MPa and temperature at 65°C, react for 1 hour, add hydroquinone to obtain polyethylene with low polymerization degree;

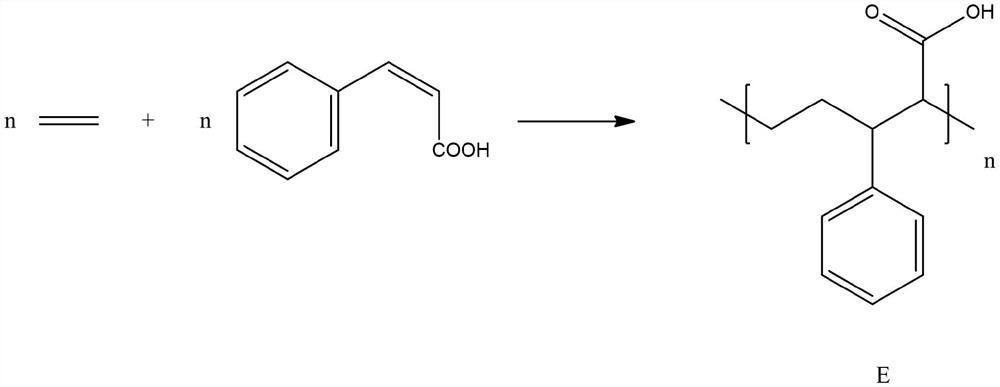

[0055] S22: adding ethylene into the reactor, and at the same time adding cinnamic acid into the reactor, reacting for 2 hours under the pressure of 0.2MPa and temperature of 70°C to obtain intermediate E;

[0056] S23: Add intermediate E to oligomeric polyethylene, add Ziegler-Natta initiator, control the pressure at 0.3MPa, react at 60°C for 3h, soak it in threonine solution for 12h, an...

Embodiment 2

[0065] This embodiment is a corrosion-resistant plastic rope, comprising the following steps:

[0066] S1: 75 parts of modified polyethylene, 15 parts of plant cellulose fiber, 18 parts of plasticizer, 1 part of foaming agent, 2 parts of corrosion inhibitor and 1 part of dispersant are mixed to obtain a blend;

[0067] Wherein the preparation process of modified polyethylene is as follows:

[0068] S21: Add ethylene to the reactor, add catalyst, control the pressure at 0.2MPa and temperature at 65°C, react for 2 hours, add hydroquinone to obtain polyethylene with low polymerization degree;

[0069] S22: Add ethylene into the reactor, and at the same time add cinnamic acid into the reactor, and react for 2 hours under the pressure of 0.2 MPa and temperature of 75° C. to obtain intermediate E;

[0070] S23: Add intermediate E to oligomeric polyethylene, add Ziegler-Natta initiator, control the pressure at 0.3MPa, react at 70°C for 3h, soak it in threonine solution for 12h, and ...

Embodiment 3

[0079] This embodiment is a corrosion-resistant plastic rope, comprising the following steps:

[0080] S1: 80 parts of modified polyethylene, 20 parts of plant cellulose fiber, 20 parts of plasticizer, 2 parts of foaming agent, 3 parts of corrosion inhibitor and 2 parts of dispersant are mixed to obtain a blend;

[0081] Wherein the preparation process of modified polyethylene is as follows:

[0082] S21: Put ethylene into the reactor, add a catalyst, control the pressure at 0.5 MPa and the temperature at 75°C, react for 3 hours, add hydroquinone to obtain polyethylene with low polymerization degree;

[0083] S22: adding ethylene into the reactor, and at the same time adding cinnamic acid into the reactor, reacting for 3 hours under the pressure of 0.3MPa and temperature of 80°C to obtain intermediate E;

[0084] S23: Add intermediate E to oligomeric polyethylene, add Ziegler-Natta initiator, control the pressure at 0.4MPa, react at 80°C for 4 hours, soak it in threonine solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com