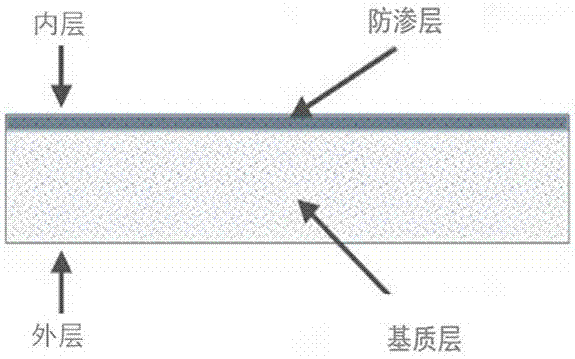

A kind of double-layer composite dura mater and preparation method thereof

A dura mater and composite type technology, which is applied to the field of double-layer composite dura mater and its preparation, can solve the problems of inability to match the growth rate of the new dura mater in the degradation rate, lack of biological activity, insufficient mechanical strength, etc., and achieve proper biodegradability. properties and biological activity, improving resistance to enzymatic degradation, and improving biological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of matrix layer

[0052] Modification of medical purified pig dermis: put 100 parts by weight of medical purified pig dermis into a stainless steel drum, add 100 parts by weight of 0.01mol / L phosphate buffer at room temperature, soak for 1 hour, and then use 0.25M Na 2 CO 3 -NaHCO 3 The buffer solution adjusts the pH of the liquid in the drum to 8.5, adds 5 parts by weight of triglycidyl isocyanurate, starts the drum, reacts for 10 hours, and the reaction temperature is 30°C;

[0053] Washing: Weigh 100 parts by weight of the modified medical purified pig dermis, add it to a stainless steel drum, add 200 parts by weight of normal temperature water, wash with water for 10 minutes, discard the waste liquid, and repeat the washing process for 3 times; add 200 parts by weight of normal temperature water , washed with water for 30 minutes, discarded the waste liquid, and repeated the washing twice; added 200 parts by weight of normal temperature water, wash...

Embodiment 2

[0064] (1) Preparation of matrix layer

[0065] Modification of medical purified pig dermis: put 100 parts by weight of medical purified pig dermis into a stainless steel drum, add 300 parts by weight of 0.05mol / L phosphate buffer at room temperature, soak for 2 hours, then use 0.25M Na 2 CO 3 -NaHCO 3 The buffer solution adjusts the pH of the liquid in the drum to 9.5, adds 12 parts by weight of triglycidyl isocyanurate, starts the drum, reacts for 15 hours, and the reaction temperature is 37°C;

[0066] Washing: Weigh 100 parts by weight of the modified medical purified pig dermis, add it to a stainless steel drum, add 300 parts by weight of normal temperature water, wash with water for 20 minutes, discard the waste liquid, and repeat the washing process 5 times; add 300 parts by weight of normal temperature water , washed with water for 45 minutes, discarded the waste liquid, and repeated water washing for 4 times; added 300 parts by weight of normal temperature water, wa...

Embodiment 3

[0077] (1) Preparation of matrix layer

[0078] Modification of medical purified pig dermis: put 100 parts by weight of medical purified pig dermis into a stainless steel drum, add 500 parts by weight of 0.1mol / L phosphate buffer at room temperature, soak for 3 hours, and then use 0.25M Na 2 CO 3 -NaHCO 3 The buffer solution adjusts the pH of the liquid in the drum to 10.5, adds 20 parts by weight of triglycidyl isocyanurate, starts the drum, reacts for 20 hours, and the reaction temperature is 42°C;

[0079] Washing: Weigh 100 parts by weight of the modified medical purified pig dermis, add it to a stainless steel drum, add 400 parts by weight of normal temperature water, wash with water for 30 minutes, discard the waste liquid, and repeat the washing for 6 times; add 400 parts by weight of normal temperature water , washed with water for 60 minutes, discarded the waste liquid, and repeated the washing for 5 times; added 400 parts by weight of normal temperature water, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com