Wire rope reel rope groove cutting machining device and application method thereof

A wire rope reel and cutting technology, which is applied in the field of wire rope reels, can solve the problem of high cost of CNC lathes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

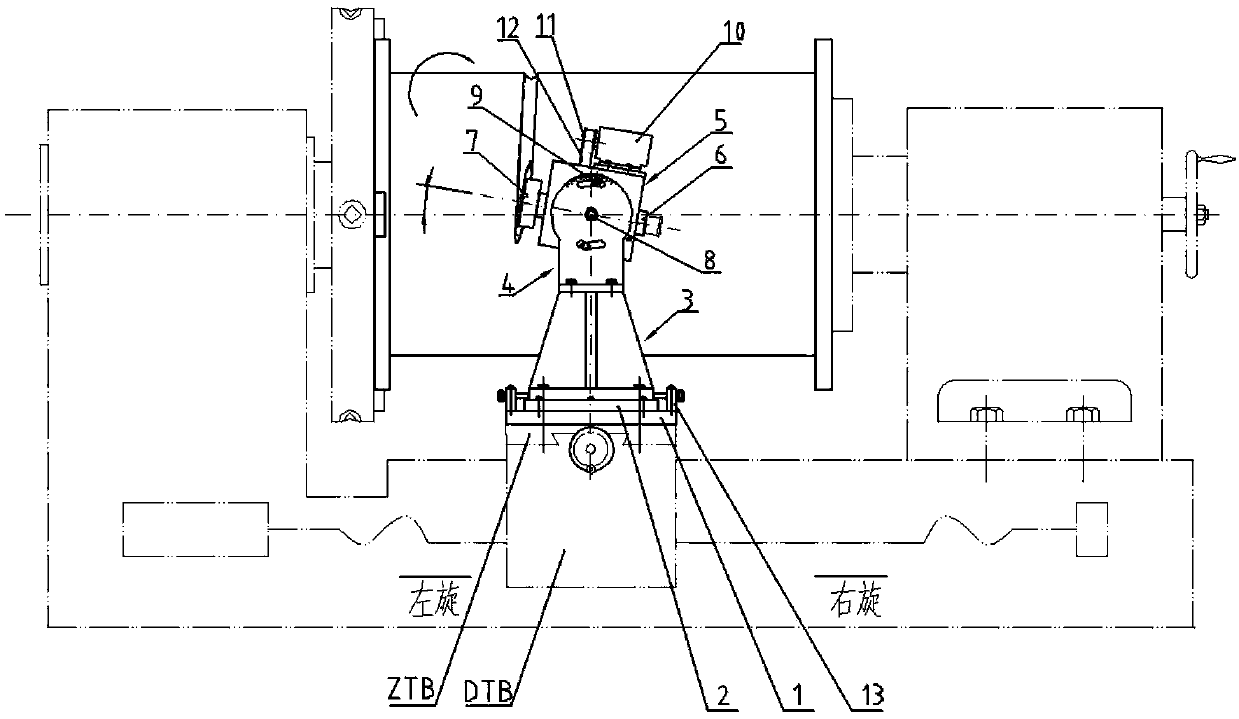

[0031] Such as figure 1 As shown, the wire rope reel rope groove cutting processing device disclosed in this embodiment includes a slide plate 1, a guide block 2, a bracket 3, a dial frame 4, a frame 5, a main shaft 6, a cutter head 7, a fulcrum bolt 8, Tighten bolt 9, motor 10, pulley 11, timing belt 12.

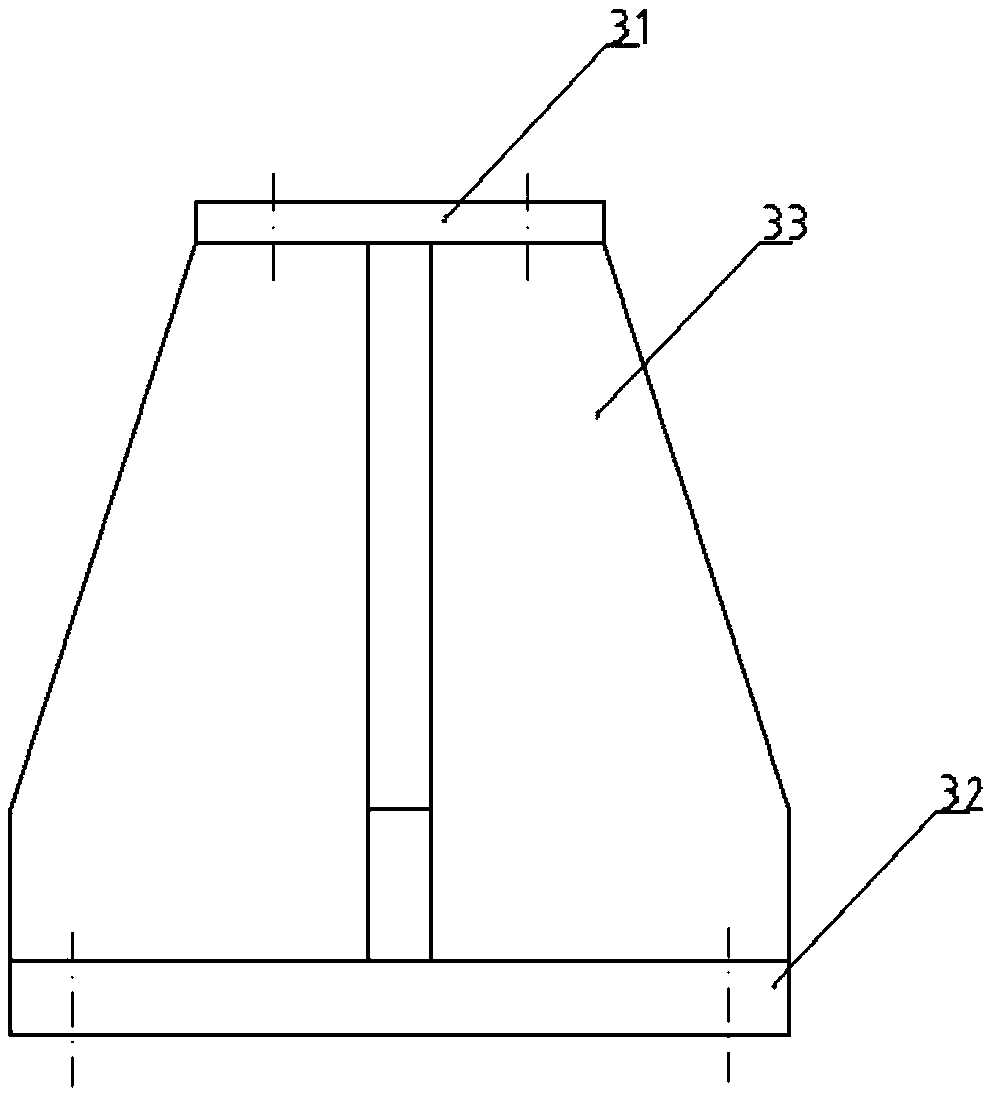

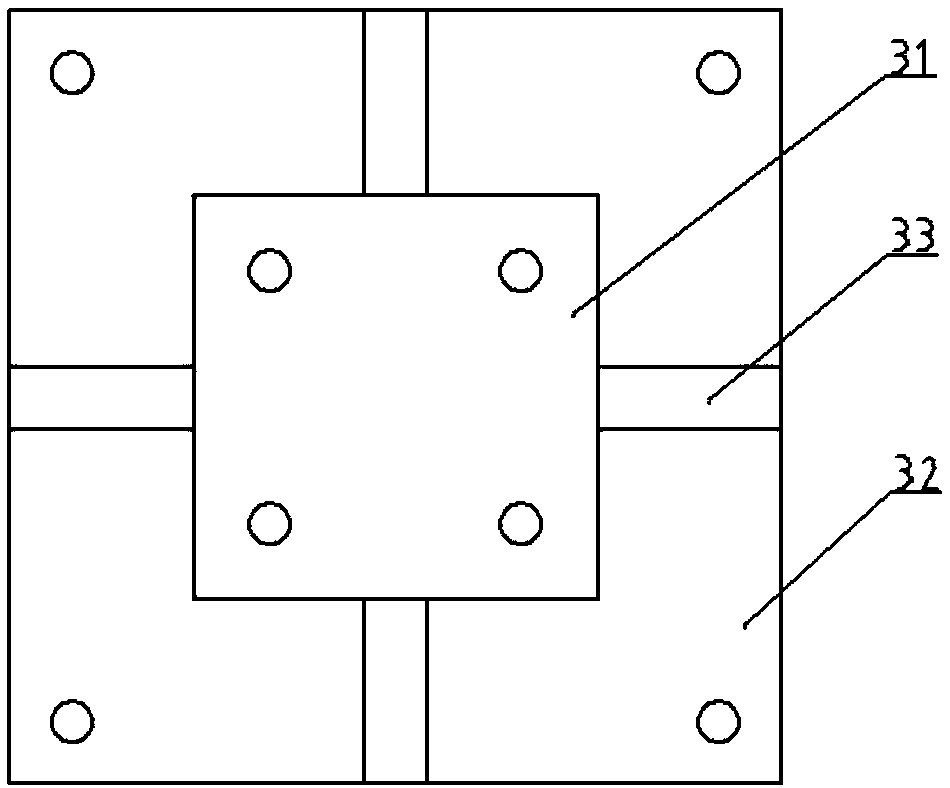

[0032] combine Figure 1 to Figure 3 It can be seen that the bracket 3 of this embodiment includes a top plate 31, a bottom plate 32 and a rib plate 33, both of which are rectangular plates arranged in parallel up and down, and the four rib plates are connected to form a cross to connect the top plate and the bottom plate.

[0033] combine figure 1 , Figure 4 and Figure 5 It can be seen that the dial frame 4 of this embodiment includes a scale plate 41 arranged along the vertical direction and a bottom plate 42 whose lower end is along the horizontal direction. The bottom plate 42 is a rectangular plate, and the upper part of the scale plate 41 is an arc-shaped scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com