Full-automatic EVA secondary foaming disk molding machine

A technology of secondary foaming and molding machine, applied in the field of rubber and plastic machinery, to achieve the effect of low cost, convenient packing and transportation, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

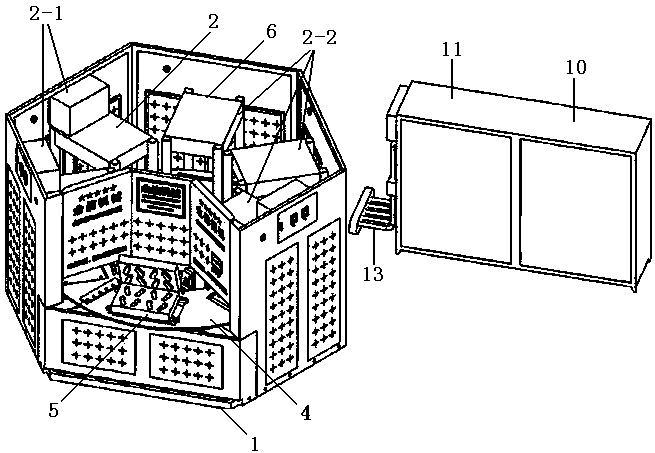

Embodiment 1

[0026]Embodiment 1: When the present invention is in the standby state, the intensive mold 5 in the unfilling mold station 2-3 is opened, and the rotational kinetic energy of the turntable 4 is disconnected. After the power supply of the present invention is connected, the starting temperature of the heating mold station 2-1, the upper limit temperature of heating, the duration of the upper limit temperature, the upper limit temperature of the ice water tank 11, and the cooling mold station 2-2 are manually controlled by the control panel. The cooling temperature is input to the controller, and when the heating mold station 2-1 reaches the starting temperature, the controller sends a warning that it can be started.

Embodiment 2

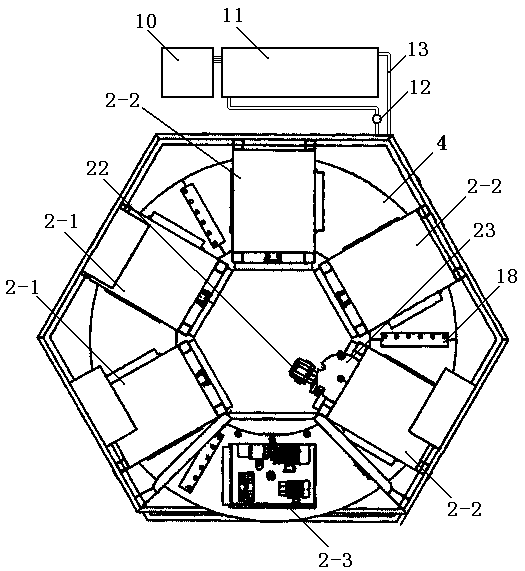

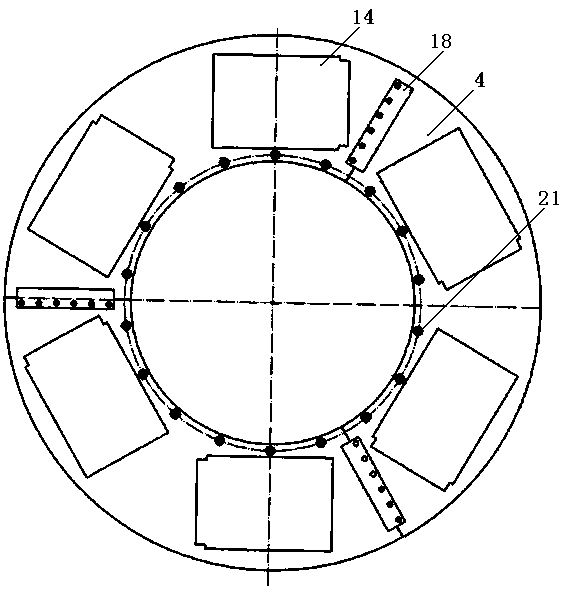

[0027] Embodiment 2: After getting the warning that can be started, manually fill the EVA raw material that has been foamed once from the upstream into the compact mold 5, and then fasten the upper cover of the mold. After the controller obtains the mold fastening information, it instructs the drive motor 22 to work , the kinetic energy of the driving motor 22 stirs the driven wheel 21 through the reducer and the gear plate 23, and the driven wheel 21 drives the turntable 4 to rotate. When the first intensive mold 5 on the turntable arrives at the first heating mold station 2-1, the controller instructs the drive motor 22 to stop rotating, and the first intensive mold 5 is positioned on the supporting plate 17 of the first heating mold station 2-1 When the top, the second intensive mold 5 arrives at the filling mold station 2-3 and is opened.

Embodiment 3

[0028] Embodiment 3: When the first intensive mold 5 is positioned above the supporting plate 17 of the first heating mold station 2-1, the controller instructs the oil cylinder 9 of the first heating mold station 2-1 to rise, and the oil cylinder 9 is connected to the oil cylinder when it rises 9 When the upper supporting plate pushes the intensive mold 5 up to the bottom of the upper cover plate 6, when the heating plate 3 heats the intensive mold 5 to the set upper limit temperature, the temperature information is transmitted to the controller through the temperature sensor, and the controller instructs the heating plate 3. While stopping heating, command the oil cylinder 9 to descend, and after the intensive mold 5 is lowered to the pallet on the channel opening 14, the system repeats until the first intensive mold 5 is transferred to the first cooling mold station 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com