A kind of modified nano-additive and its application in lubricating oil

A nano-additive and lubricating oil technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of difficult dispersion, easy moisture absorption and easy agglomeration of hexagonal boron nitride, and achieve the effect of excellent friction and wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of modified nano-additive, concrete steps are as follows:

[0029] 1) Preparation of silane coupling agent hydrolysis base fluid

[0030] Take 20ml of deionized water, add dropwise 0.2g of silane coupling agent (A-151) into the deionized water for hydrolysis, and react for 15min to obtain the hydrolysis base solution.

[0031] 2) Preparation of hexagonal boron nitride-vinyltriethoxysilane

[0032] Take 2g of hexagonal boron nitride in the silane coupling agent hydrolysis base solution, stir in a constant temperature magnetic stirrer for 20 minutes, ultrasonically treat in an ultrasonic cleaner for 20 minutes, pour into a petri dish, and carry out in a vacuum dryer at 100°C drying, using a planetary ball mill for 30 minutes, washing, filtering, and drying at 60°C to obtain hexagonal boron nitride-vinyltriethoxysilane nano additives.

Embodiment 2

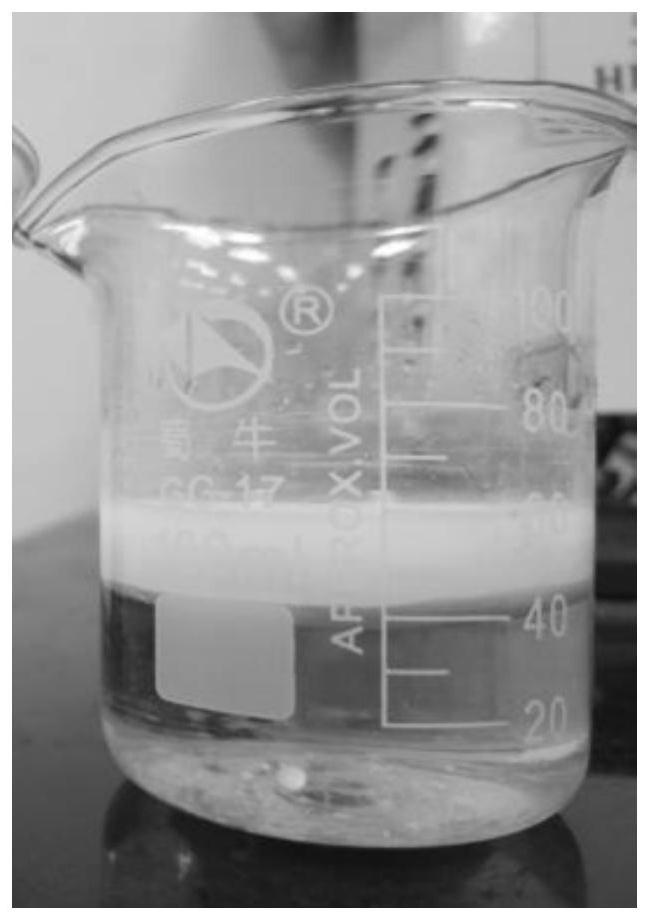

[0034] Example 1 Application of modified nano additives in lubricating oil, put modified hexagonal boron nitride into a beaker filled with paraffin wax and deionized water layered up and down. Put unmodified hexagonal boron nitride into a beaker filled with paraffin wax and deionized water layered up and down, as a control.

[0035] Such as figure 1 and 2 As shown, the upper layer of the solution contained in the beaker is paraffin, and the lower layer is deionized water. figure 1 It can be seen that unmodified hexagonal boron nitride is distributed in deionized water, exhibiting hydrophilicity, by figure 2 It can be seen that the modified hexagonal boron nitride is distributed in paraffin wax, showing lipophilic and hydrophobic properties.

Embodiment 3

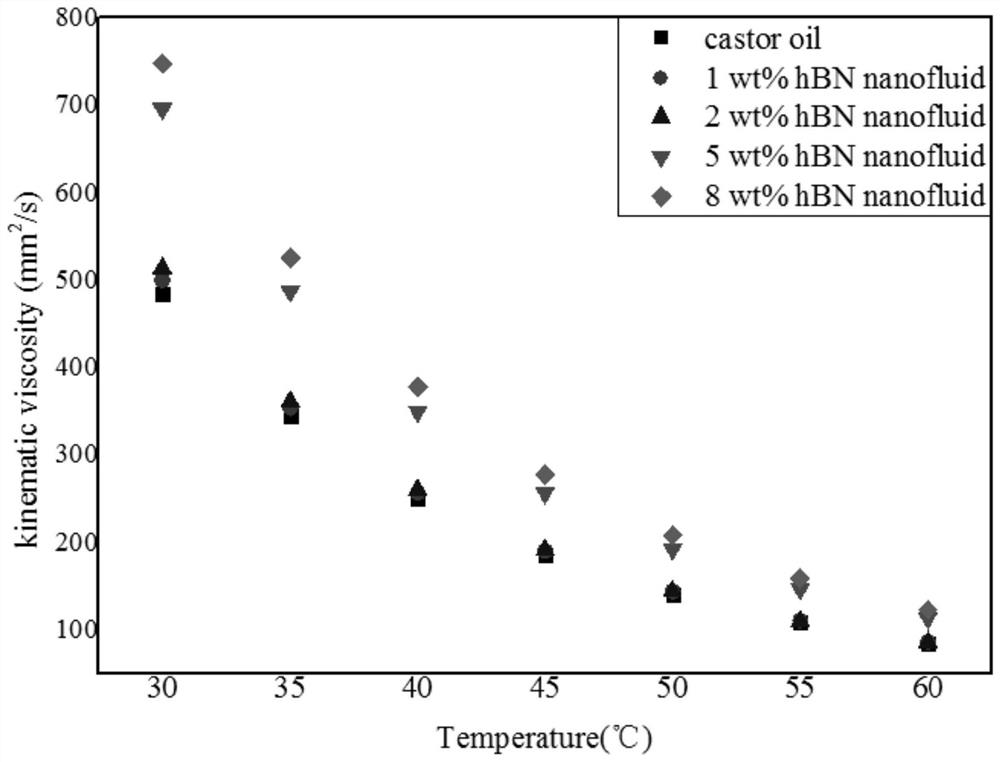

[0037] The application of embodiment 1 modified nano additives in lubricating oil, add 0.1g hexagonal boron nitride-vinyltriethoxysilane nano additives in 9.9g castor oil, stir 20min in constant temperature magnetic stirrer, and in 60 Ultrasonic treatment at ℃ for 1 h, and standing for 24 h to obtain 1 wt% nanofluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com