Coating thickness measuring method and measuring system

A technology of coating thickness and measurement method, applied in the field of coating thickness measurement method and measurement system, can solve problems such as narrow application range, and achieve the effects of convenient operation, fast analysis speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

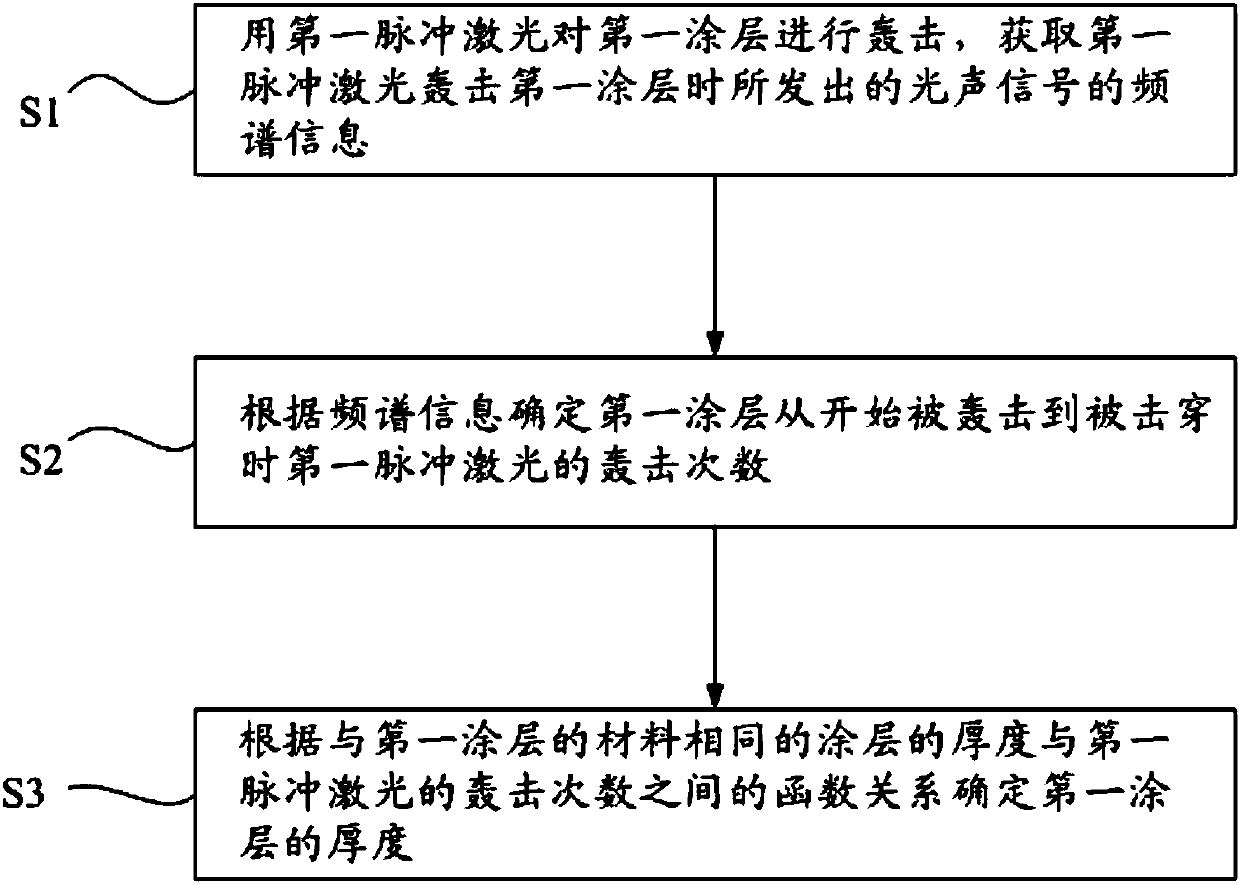

[0026] see figure 1 , the embodiment of the present invention provides a method for measuring coating thickness, comprising the following steps:

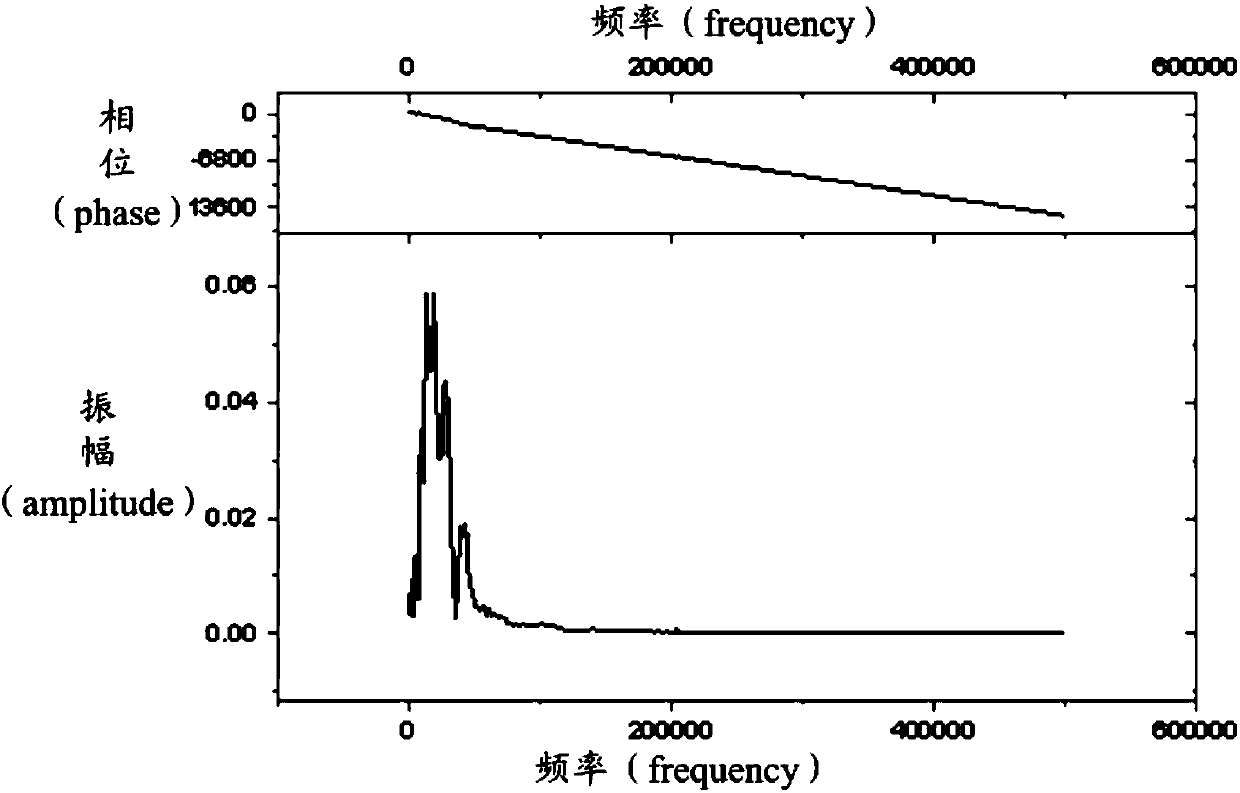

[0027] S1. Bombard the first coating with the first pulse laser, and acquire the spectrum information of the photoacoustic signal emitted when the first pulse laser bombards the first coating;

[0028] Among them, the first pulse laser can be a pulse laser with the following parameters set: the wavelength is 1064nm, the single pulse energy is 100mJ, the frequency is 2Hz, and the pulse width is 7ns; the first coating is the coating with the thickness to be measured, for example, it can be coated For RTV coatings on composite insulators, the substrate on which the first coating is applied is of a different material than the first coating.

[0029] S2. Determine the bombardment times of the first pulse laser from the beginning of being bombarded to the breakdown of the first coating according to the spectrum information;

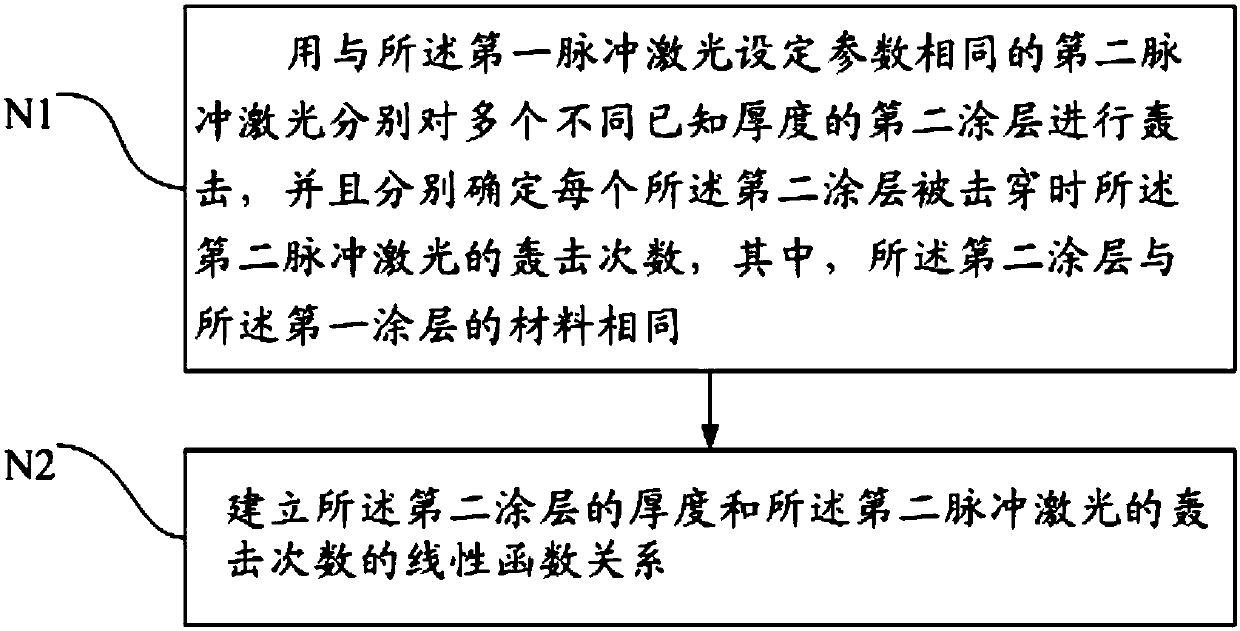

[0030] S3. D...

Embodiment 2

[0048] see Figure 6 , the embodiment of the present invention provides a coating thickness measurement device, including: a detection module 1, the detection module 1 is used to detect the photoacoustic signal emitted when the pulsed laser bombards the first coating, and convert the photoacoustic signal into Electric signal; processing module 2, processing module 2 is connected with detection module 1, and processing module 2 is used for receiving electric signal, obtains the spectrum information of photoacoustic signal according to electric signal, determines coating from being bombarded to being hit according to spectrum information The number of bombardments of the pulsed laser is timed, and the thickness of the first coating is determined according to the functional relationship between the thickness of the coating of the same material as the first coating and the number of bombardments of the pulsed laser. Wherein, the detection module 1 may be an ultrasonic sensor; the ...

Embodiment 3

[0053] see Figure 6 , the embodiment of the present invention provides a measurement system for coating thickness, including a laser 200 (for example, a Q-tunable nanosecond pulsed laser), a focusing lens 300 and the coating thickness measurement device 100 described in Embodiment 2, focusing The lens 300 is located on the path of the laser light emitted by the laser 200 .

[0054] In the coating thickness measuring system provided by the embodiment of the present invention, when measuring the thickness of the first coating 600, the laser 200 emits pulsed laser light, and the pulsed laser beam reaches a sufficient energy density to bombard the surface of the first coating 600 after being focused by the focusing lens 300 , so that the first coating 600 is excited to generate plasma, thereby generating the required photoacoustic signal, the coating thickness measuring device 100 can determine according to the spectral information of the photoacoustic signal that the first coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com