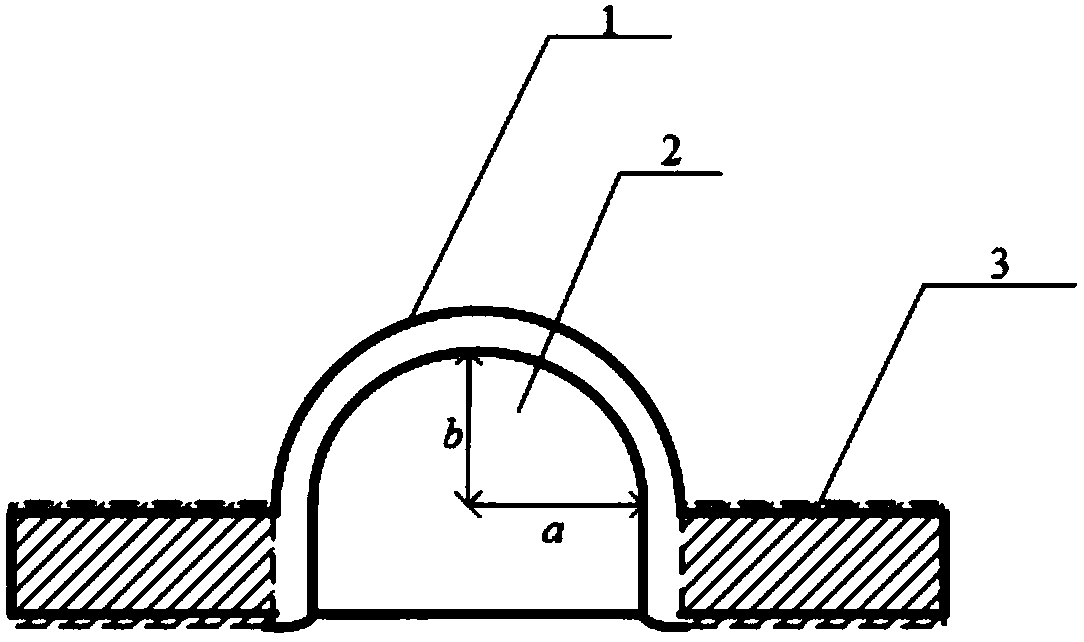

Piezoelectric film sensor with elliptical flexible substrate

A flexible substrate and piezoelectric film technology, applied in the field of sensors, can solve the problems of inconvenient production of sensor substrates, and achieve the effects of miniaturization and arraying, small size and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

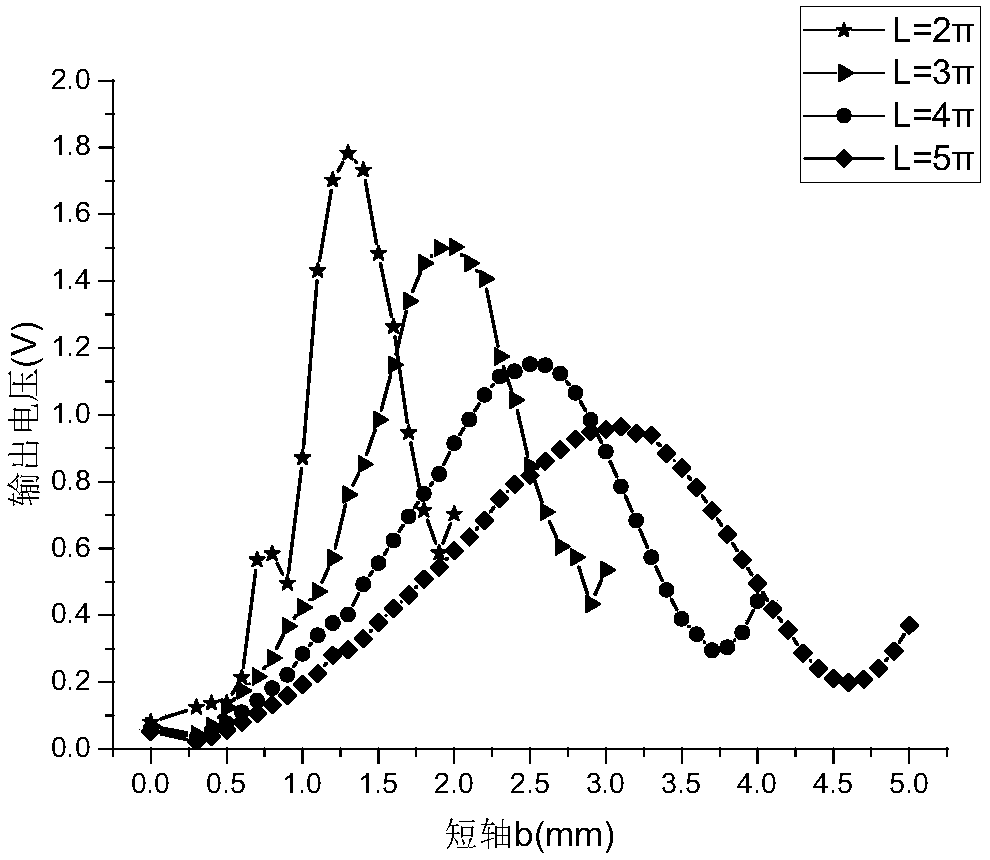

[0037] Example 1: When the arc length L is fixed, for the semi-elliptical base, the value of a can be uniquely determined according to the value of b. According to the semi-ellipse arc length formula: L=πb+2(a-b); so the major axis can be obtained as:

[0038] If the lengths L of the PVDF piezoelectric film are 2π, 3π, 4π, and 5π (unit: mm), respectively, the value ranges of the major axis a and minor axis b of the semi-ellipse base for each arc length are shown in Table 1. When the PVDF piezoelectric film with the corresponding arc length is covered on the substrate with different long and short axes, when the top of the sensor is subjected to a concentrated force of 1N, the open circuit voltage of the sensor is as follows: figure 2shown. The leftmost point of each curve is a plane base when b=0, the rightmost point is a semicircle base when a=b, and the remaining points are ellipses. Depend on figure 2 It can be seen that in each case of equal arc length, the sensitiv...

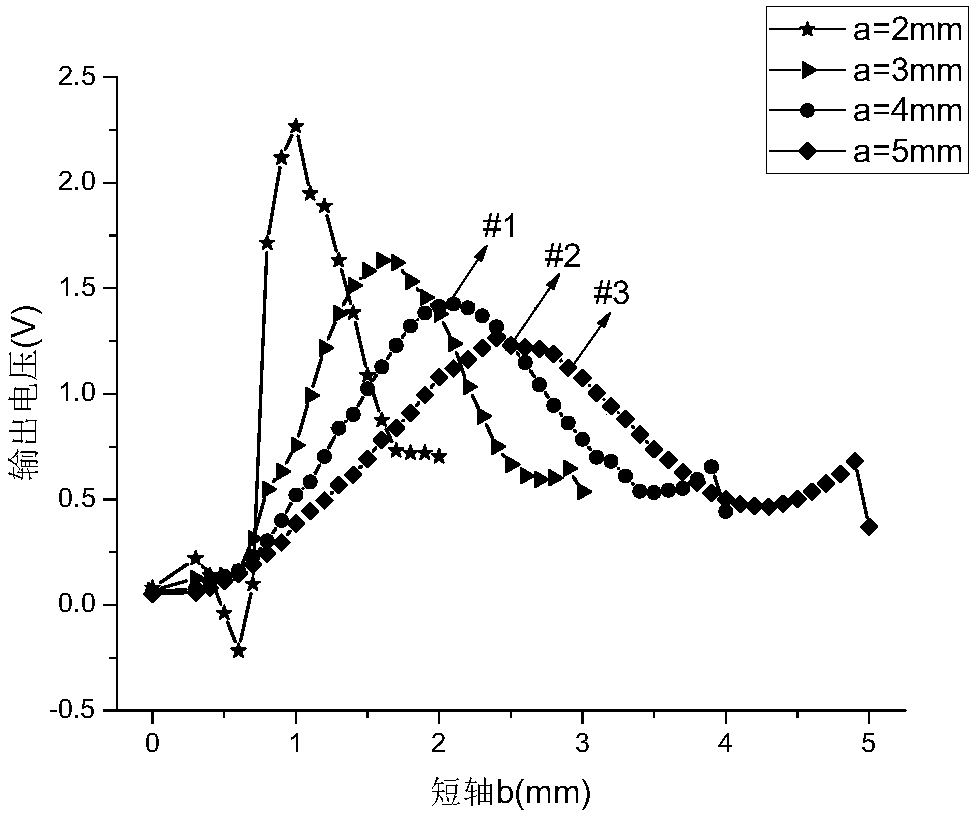

Embodiment 2

[0042] Embodiment 2: The present invention has produced three kinds of size ellipse flexible substrate piezoelectric sensors, and the major and minor axis parameters are as shown in Table 2, in image 3 The positions of the three sensors on the corresponding curves are marked in . And three kinds of piezoelectric film sensors are used to measure human pulse, the piezoelectric film sensor 5 is connected with the charge amplifier 6, and the charge amplifier 6 is connected with the oscilloscope 7. The piezoelectric film sensor 5 is placed on the wrist of the human body, the human pulse force 4 is applied to the piezoelectric film sensor 5 , and finally the pulse wave pattern is obtained on the oscilloscope 7 . The human pulse measured by the three sensors recorded by the oscilloscope 7 is as follows: Figure 5-7 As shown in Fig. 1, and filtered the pulse graph, by comparing the graphs before and after filtering, it can be found that the waveforms measured by the three sensors ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com