Intelligent optimization control method of unit load based on energy storage of cold end system

A control method and unit load technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of not considering the influence of important cold-end parameters such as condenser and steam turbine work, and the decline of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to deepen the understanding of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is exemplary and is only used to explain the present invention and not limit the scope of protection.

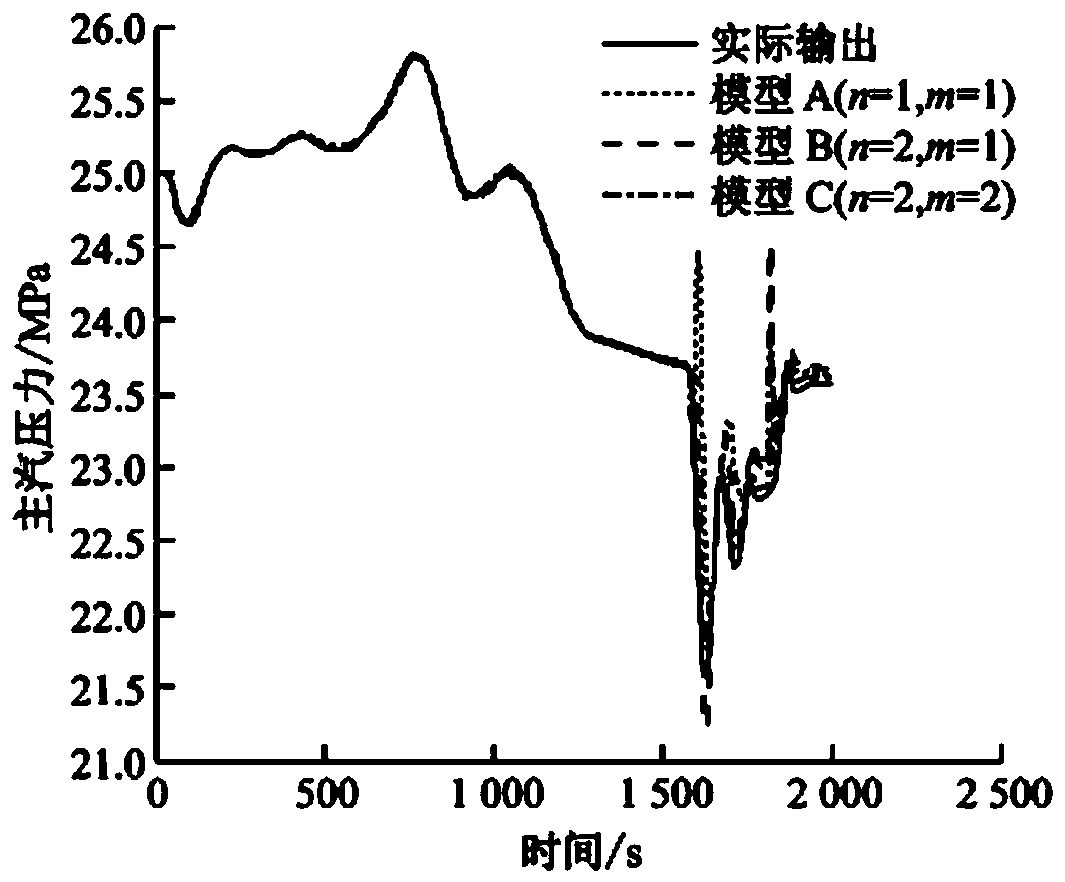

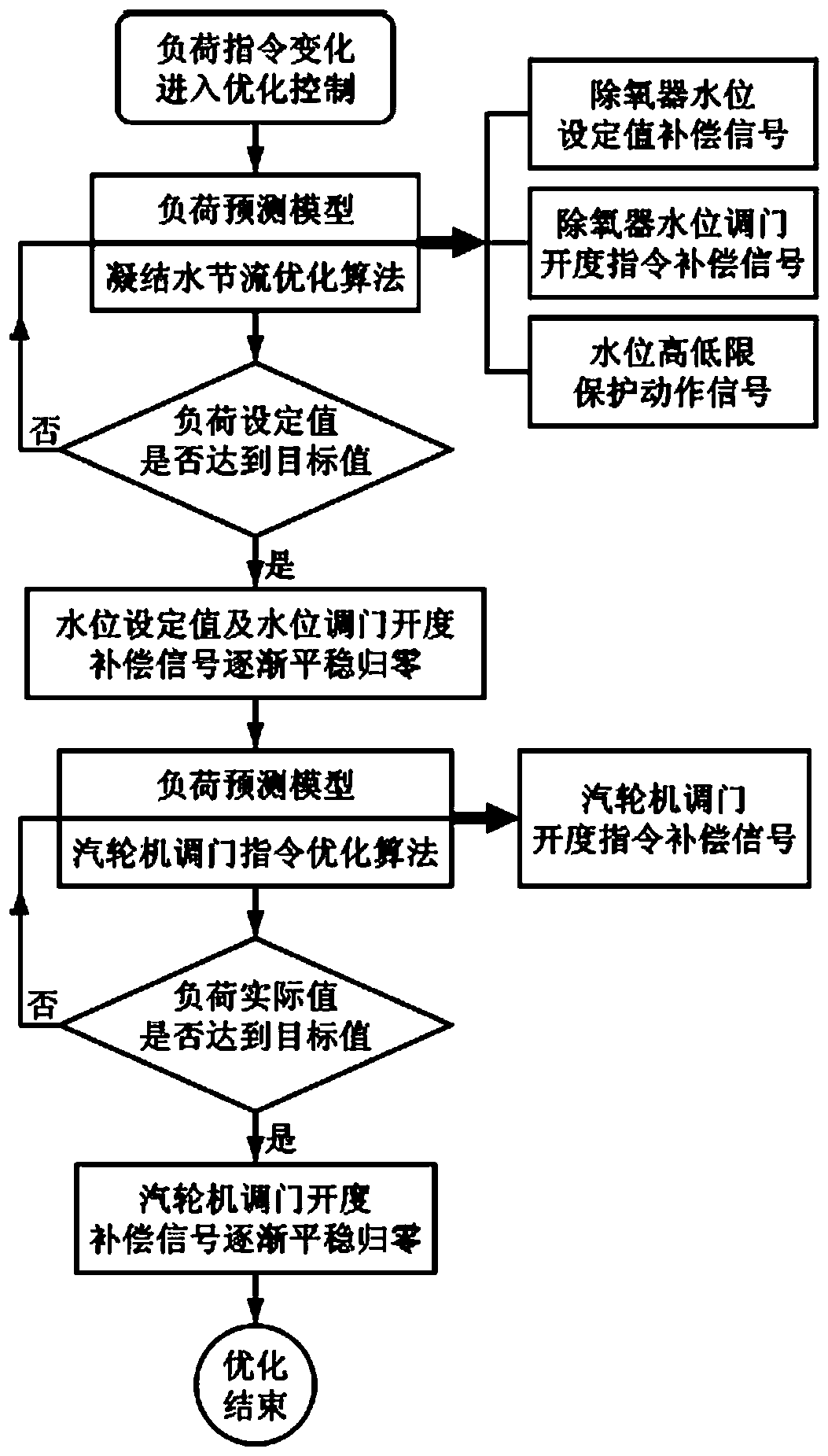

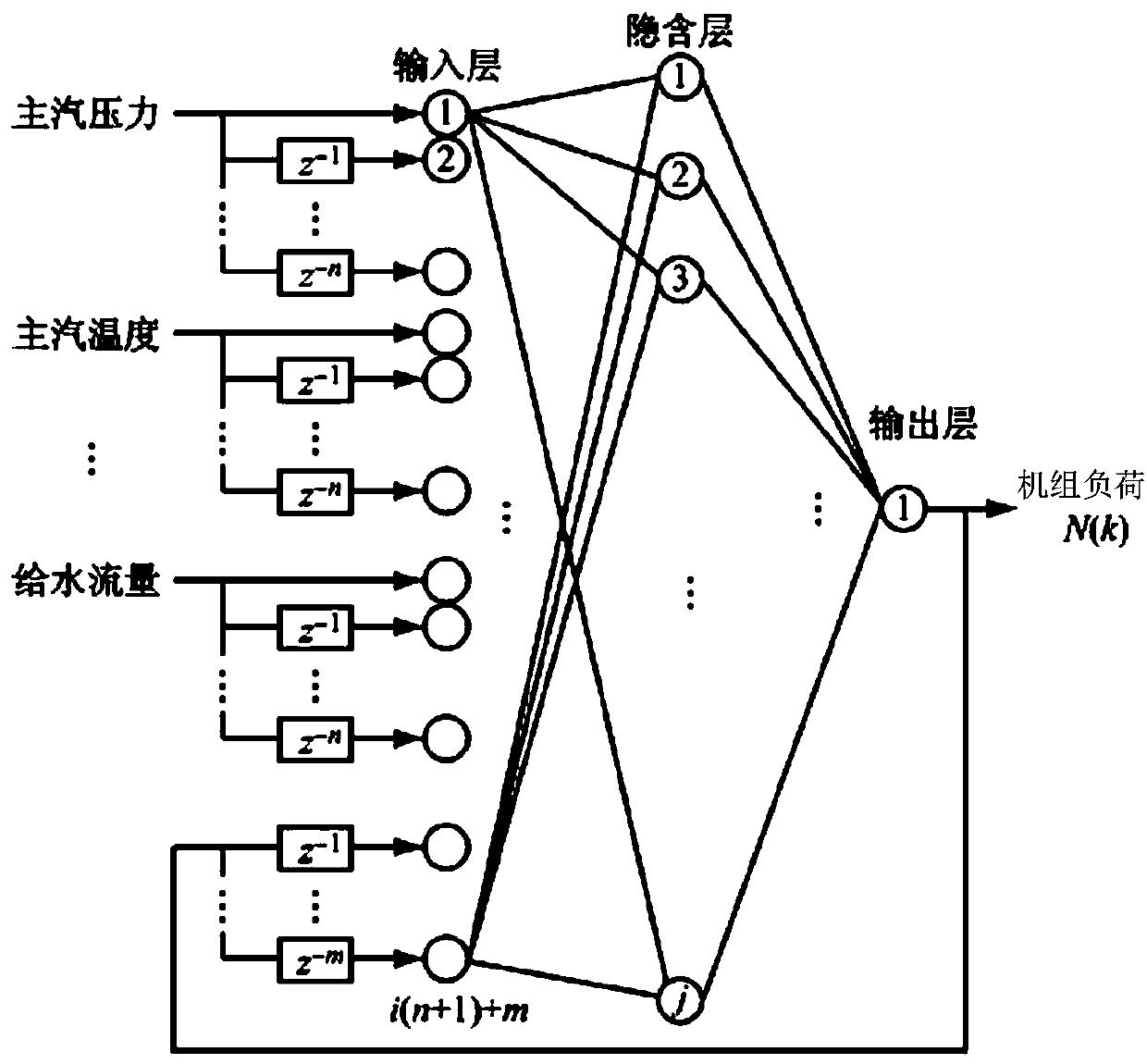

[0031] An intelligent optimal control method for unit load based on the cold end system. The method first establishes a supercritical unit load characteristic neural network prediction model, and uses the historical operation data of the unit to train and verify the prediction model, and then uses the prediction model in the unit. The cold-end energy storage system is predicted and optimized in the dynamic load change stage and load stabilization stage, and then the deviation between each optimization result and the original control instruction is superimposed on the corresponding control signal as a compensation signal to implement optimal control of the unit.

[0032] The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com