Dried mangos and making method thereof

A technology of dried mangoes and mangoes, which is applied in food drying, preservation of fruits/vegetables through dehydration, food ingredients as taste improvers, etc. It can solve the problems of poor taste of final products, affecting product quality, and reduced nutrition of dried mangoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

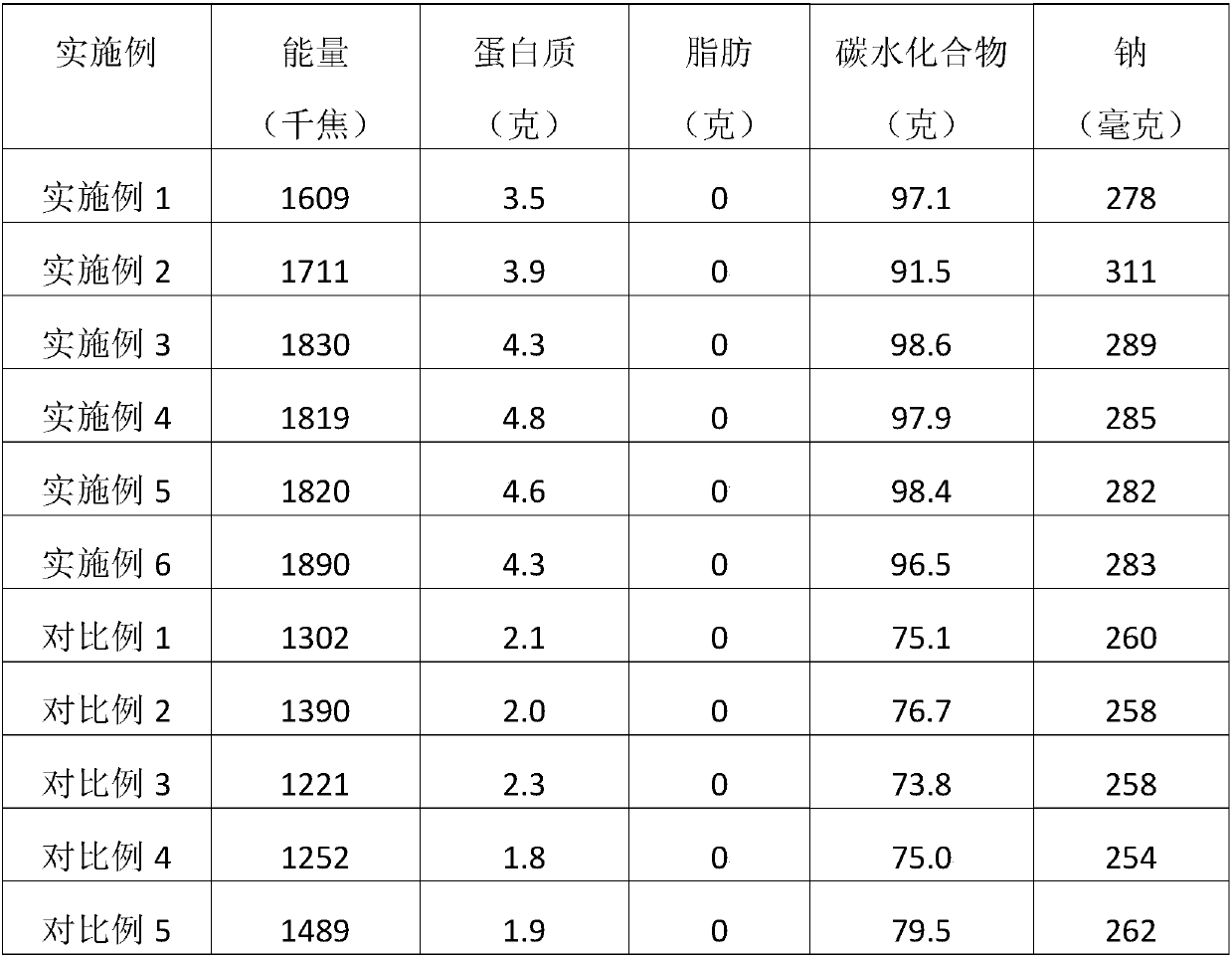

Examples

preparation example Construction

[0026] The present invention proposes a kind of preparation method of dried mango, comprises following preparation steps:

[0027] S1. Select ripe mango slices and add them to tea water containing vitamin C or citric acid, and keep at 0-4°C for 1-3 minutes;

[0028] S2. It takes 30 minutes to gradually increase the temperature to 50-60°C and dry at a constant temperature until the water content is 20-30%;

[0029] S3. Stir the mango slices, salt and sugar evenly, heat to 45-50°C, ultrasonically pickle for 2-3 hours, then stand at 55-60°C for 1-2 hours, and finally add citric acid solution, 30~40℃ low-temperature ultrasonic dipping for 2~3 hours;

[0030] S4, drying the mango slices soaked in sugar for 5 to 6 hours, and freezing at -4 to 0°C for 1 to 2 hours;

[0031] S5. Vacuum drying is carried out in three stages: the first stage is to take 30 minutes to gradiently heat up to 50°C and dry at a constant temperature for 6 hours; the second stage is to take 30 minutes to grad...

Embodiment 1

[0035] A preparation method of dried mango, comprising the following preparation steps:

[0036] S1. Select ripe mango slices and add them to green tea tea water containing 0.1% vitamin C by mass fraction, and keep it at 0°C for 1-3min. The tea water used is made from tea leaves and water in a weight ratio of 3:100;

[0037] S2. It took 30 minutes to gradually increase the temperature to 50°C and dry at a constant temperature until the water content was 20-30%;

[0038] S3. Stir 1,000 kg of mango slices, 0.5 kg of salt, and 40 kg of sucrose evenly, heat to 45°C, ultrasonically confection for 3 hours, then stand at 55°C for 2 hours, and finally add 0.1% Citric acid aqueous solution, 30 ℃ low-temperature ultrasonic sugaring for 3 hours;

[0039] S4, drying the mango slices soaked in sugar for 5 hours, and freezing at -4°C for 1 hour;

[0040] S5. Vacuum drying is carried out in three stages: the first stage is to take 30 minutes to gradiently heat up to 50°C and dry at a const...

Embodiment 2

[0043] A preparation method of dried mango, comprising the following preparation steps:

[0044] S1. Select ripe mango slices and add them to black tea tea water containing 0.2% citric acid by mass fraction, and keep it at 4°C for 1-3min. The tea water used is made from tea leaves and water in a weight ratio of 4:100;

[0045] S2. It takes 30 minutes to gradually increase the temperature to 60°C and dry at a constant temperature until the water content is 20-30%;

[0046] S3. Stir 1,000 kg of mango slices, 5 kg of salt, and 80 kg of glucose evenly, heat to 50°C, ultrasonically confection for 2 hours, then stand at 60°C for 1 hour, and finally add 0.2% Citric acid aqueous solution, 40 ℃ low-temperature ultrasonic sugaring for 2 hours;

[0047] S4, drying the mango slices soaked in sugar for 6 hours, and freezing at 0°C for 2 hours;

[0048] S5. Vacuum drying is carried out in three stages: the first stage is to take 30 minutes to gradiently heat up to 50°C and dry at a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com