Carbon nanoparticle inhibitor and application thereof

A technology of carbon nanoparticles and inhibitors, which is applied in the application, preservation of meat/fish with chemicals, food ingredients as antioxidants, etc., to achieve good inhibitory effect, inhibit harmful substances, and benefit human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

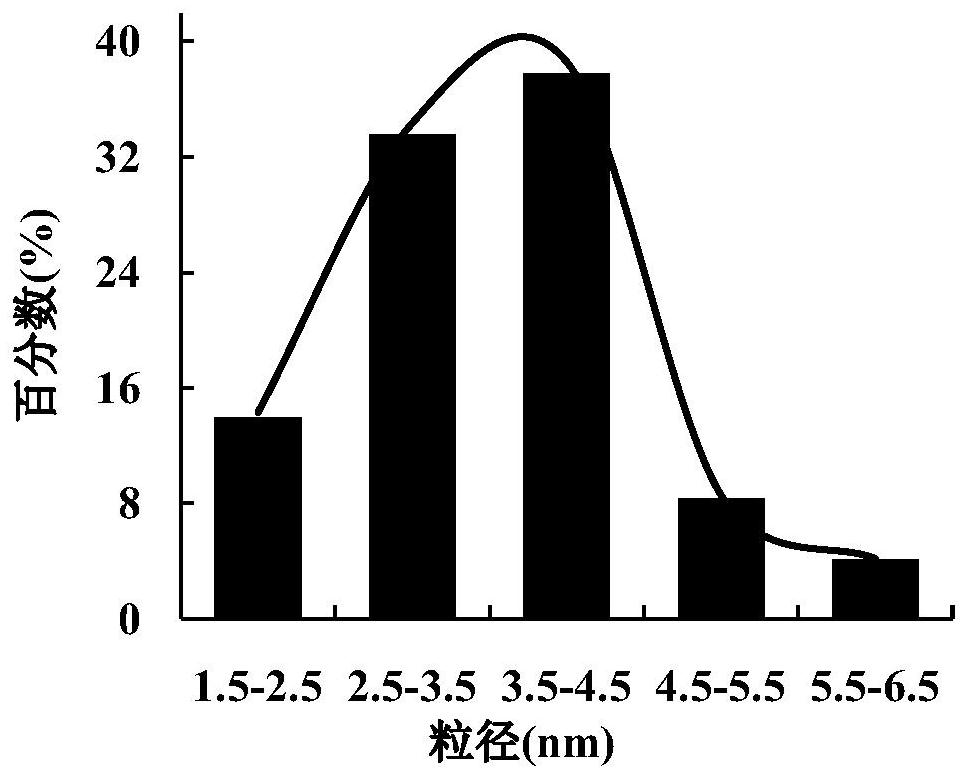

[0028] The carbon nanoparticle suppression of the present embodiment includes the following components and their weight ratios:

[0029] 0.2 parts of tea polyphenols;

[0030] 1.5 parts of gellan gum;

[0031] Sodium nitrite 0.03 parts.

[0032] The preparation method of the carbon nanoparticles in this embodiment is to mix 0.2 grams of tea polyphenols, 1.5 grams of gellan gum and 0.03 grams of sodium nitrite respectively and mix well.

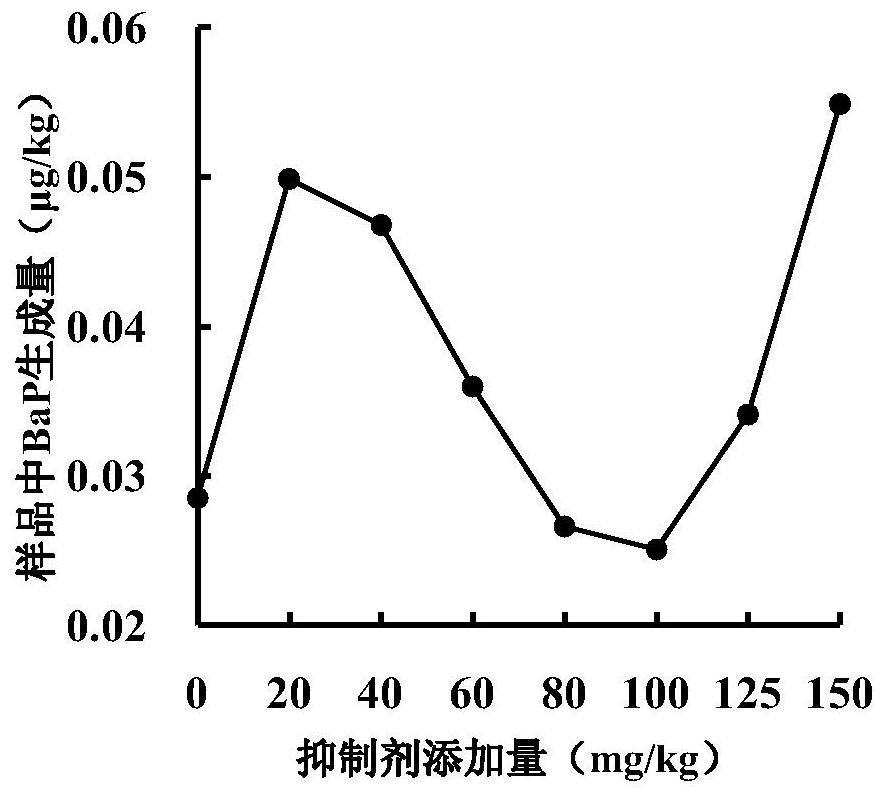

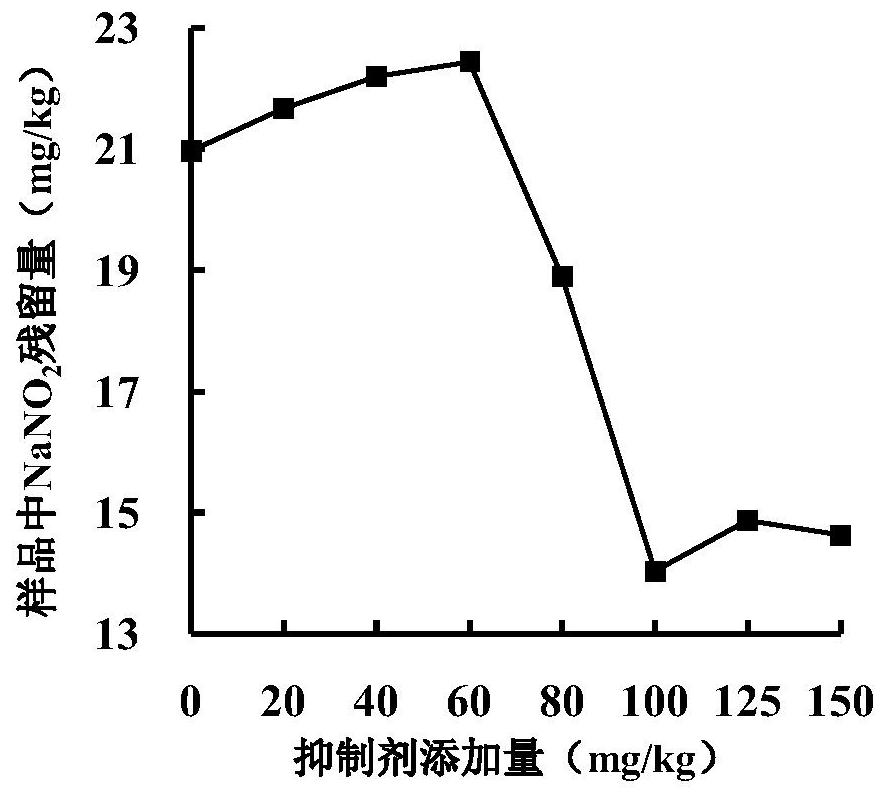

[0033] The carbon nanoparticles of this embodiment can be used to suppress harmful substances produced during high-temperature processing of pork. The suppression process is as follows: add 85 mg of carbon nanoparticle inhibitors to each kilogram of pork to be processed, add water and soak for 40 minutes, An average of 50 milliliters of water is added to each kilogram of pork to be processed before high-temperature processing.

[0034] The high-temperature processing in this embodiment includes processes such as frying, frying, steaming, an...

Embodiment 2

[0036] The carbon nanoparticle suppression of the present embodiment includes the following components and their weight ratios:

[0037] 0.1 parts of tea polyphenols;

[0038] 1.25 parts of gellan gum;

[0039] Sodium nitrite 0.015 parts.

[0040] The preparation method of the carbon nanoparticles in this embodiment is to mix 0.1 g of tea polyphenols, 1.25 g of gellan gum and 0.015 g of sodium nitrite respectively and mix well.

[0041] The carbon nanoparticles of this embodiment can be used to suppress harmful substances produced during high-temperature processing of beef. The suppression process is as follows: add 50 mg of carbon nanoparticle inhibitors to each kilogram of beef to be processed, add water and soak for 25 minutes, An average of 60 milliliters of water is added to each kilogram of beef to be processed before high-temperature processing.

[0042] The high-temperature processing in this embodiment includes processes such as frying, frying, steaming, and boilin...

Embodiment 3

[0044] The carbon nanoparticle suppression of the present embodiment includes the following components and their weight ratios:

[0045] 0.3 parts of tea polyphenols;

[0046] 1.75 parts of gellan gum;

[0047] Sodium nitrite 0.04 parts.

[0048] The preparation method of the carbon nanoparticles in this embodiment is to mix 0.3 grams of tea polyphenols, 1.75 grams of gellan gum and 0.04 grams of sodium nitrite respectively and mix well.

[0049] The carbon nanoparticles of the present embodiment can be applied to suppress harmful substances produced in the high-temperature processing mutton process, and its suppression process is: add 120 mg of carbon nanoparticle inhibitors in every kilogram of mutton to be processed, add water and soak for 50 minutes, An average of 70 milliliters of water is added to each kilogram of mutton to be processed before high-temperature processing.

[0050] The high-temperature processing in this embodiment includes processes such as frying, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com