CSP (Chip Scale Package) light source and manufacturing method and manufacturing die for same

A technology for manufacturing molds and light sources, applied in the field of lighting, can solve the problems of reduced luminous flux of light sources, separation of fluorescent colloids and light-emitting chips, insufficient brightness in the center of the light source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

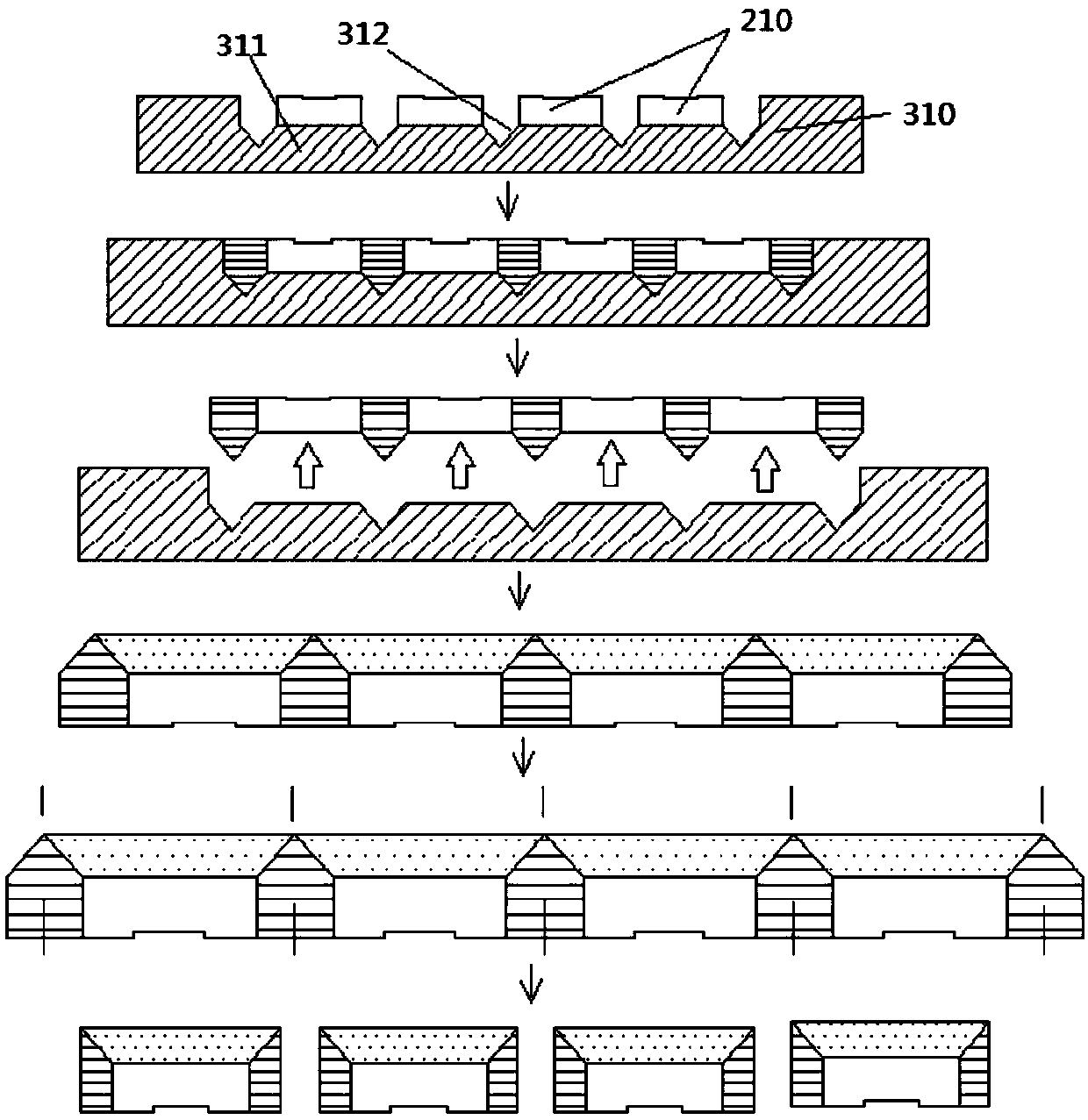

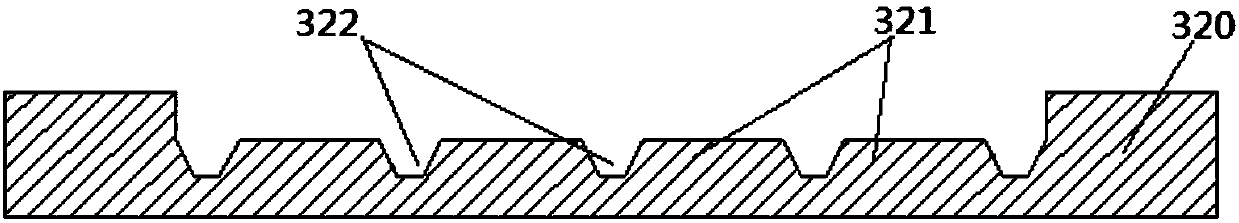

Method used

Image

Examples

Embodiment Construction

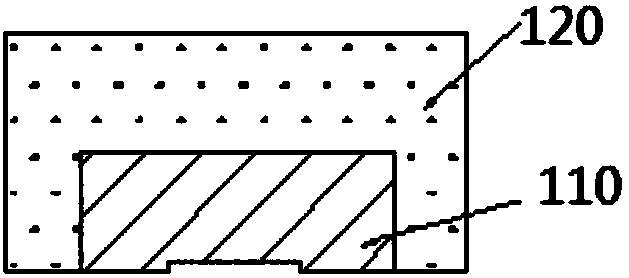

[0046] see Figure 3-5 , Embodiment 1 of the CSP light source of the present invention, which includes a light-emitting chip 210, a fluorescent colloid layer 220 is provided on the top of the light-emitting chip 210, and a light-reflective glue layer 230 with light-reflecting properties is surrounded around the light-emitting chip 210. The bonding part of the reflective adhesive layer 230 is an inclined structure, so that the fluorescent colloid layer 220 forms a structure with a large top and a small bottom, which can gather the light emitted by the flip chip on the top of the light source, such as Figure 5 As shown, the leakage of light from the bottom is well avoided, and the overall light extraction efficiency of the light source is improved.

[0047] In this embodiment, the junction of the fluorescent colloid layer 220 and the reflective adhesive layer 230 is a slope, the fluorescent colloid layer is an inverted trapezoid, and the intersection of the fluorescent colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com