Remote integrated control system of traction site for ultrahigh-voltage power transmission engineering

An integrated control system, UHV technology, applied in the direction of overhead line/cable equipment, etc., can solve the problem of low degree of automation, and achieve the effect of reducing personnel, improving degree and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

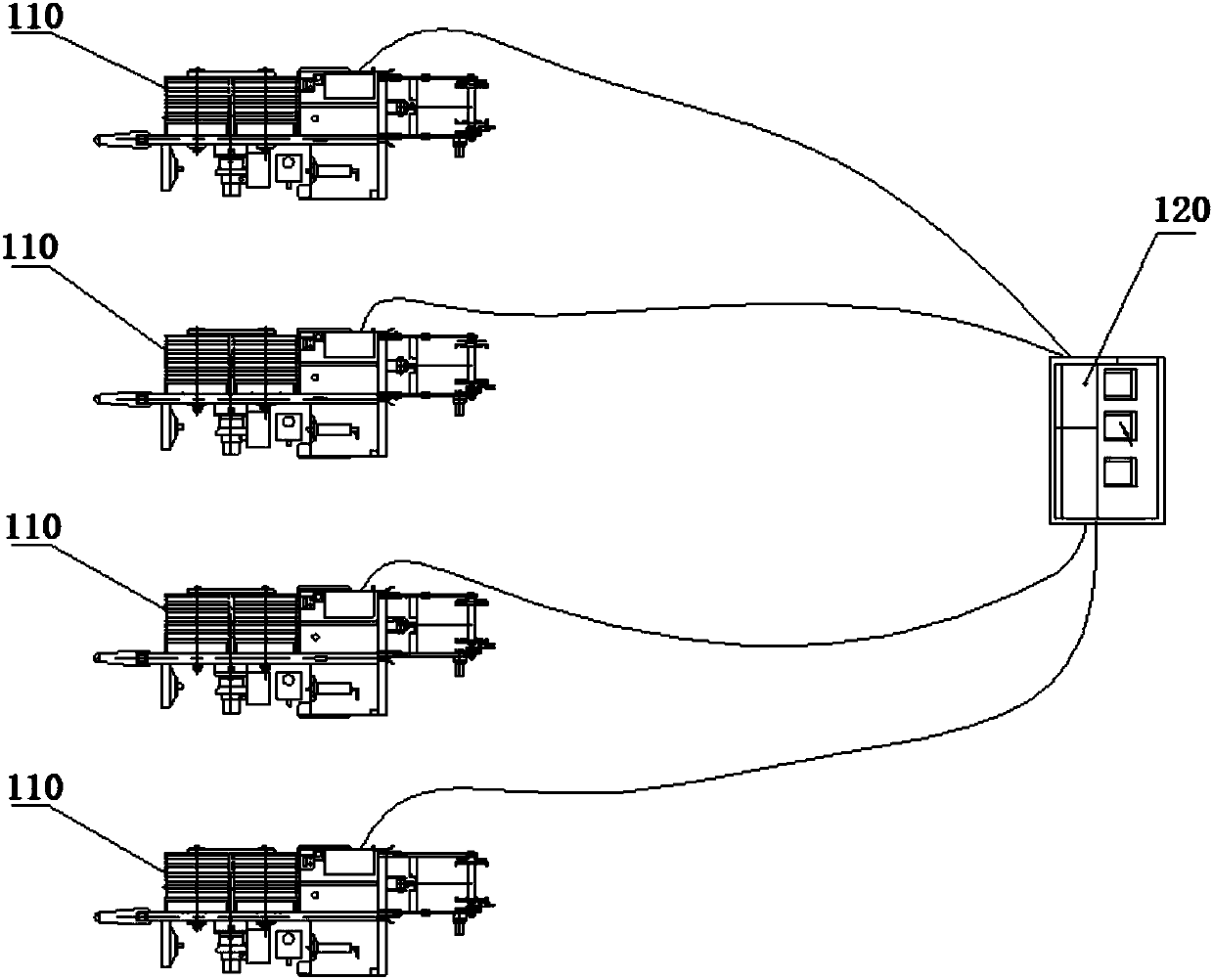

[0017] The present invention provides a traction field remote integrated control system for UHV power transmission projects, including up to four intelligent traction machines 110, a centralized control room 120 and corresponding control cables.

[0018] Its overall structure, executive mechanism and hydraulic system of intelligent tractor 110 are roughly the same as traditional tractors, mainly including chassis, traction wheel, tail rope wheel frame, control instrument box and other auxiliary devices. Different from the traditional tractor, the main hydraulic system of the intelligent tractor 110 is effectively integrated through a specially designed screw-in cartridge valve group, and more importantly, the electrical control system of the intelligent tractor 110 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com