Motor fault detection system and method based on total harmonic coefficient of current

A harmonic coefficient and fault detection technology, which is applied in the field of motor fault detection system based on current total harmonic coefficient, can solve problems such as inability to accurately detect motor fault types, and achieve the effect of protecting safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

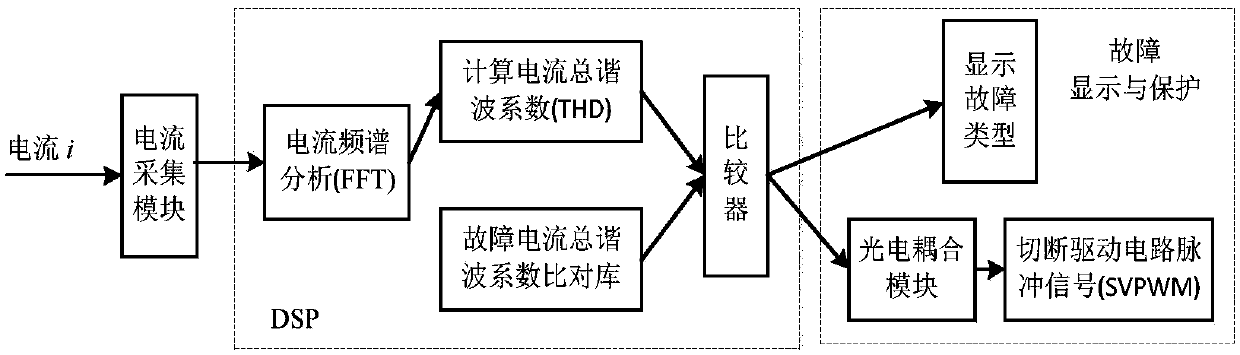

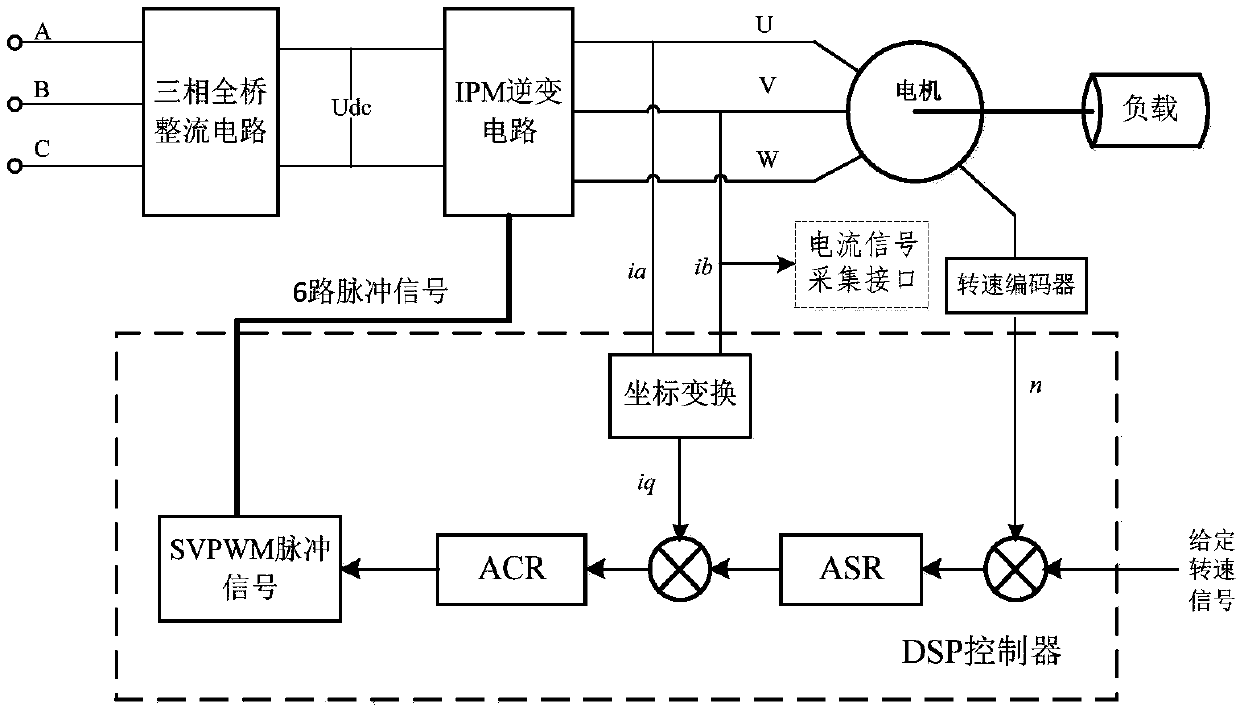

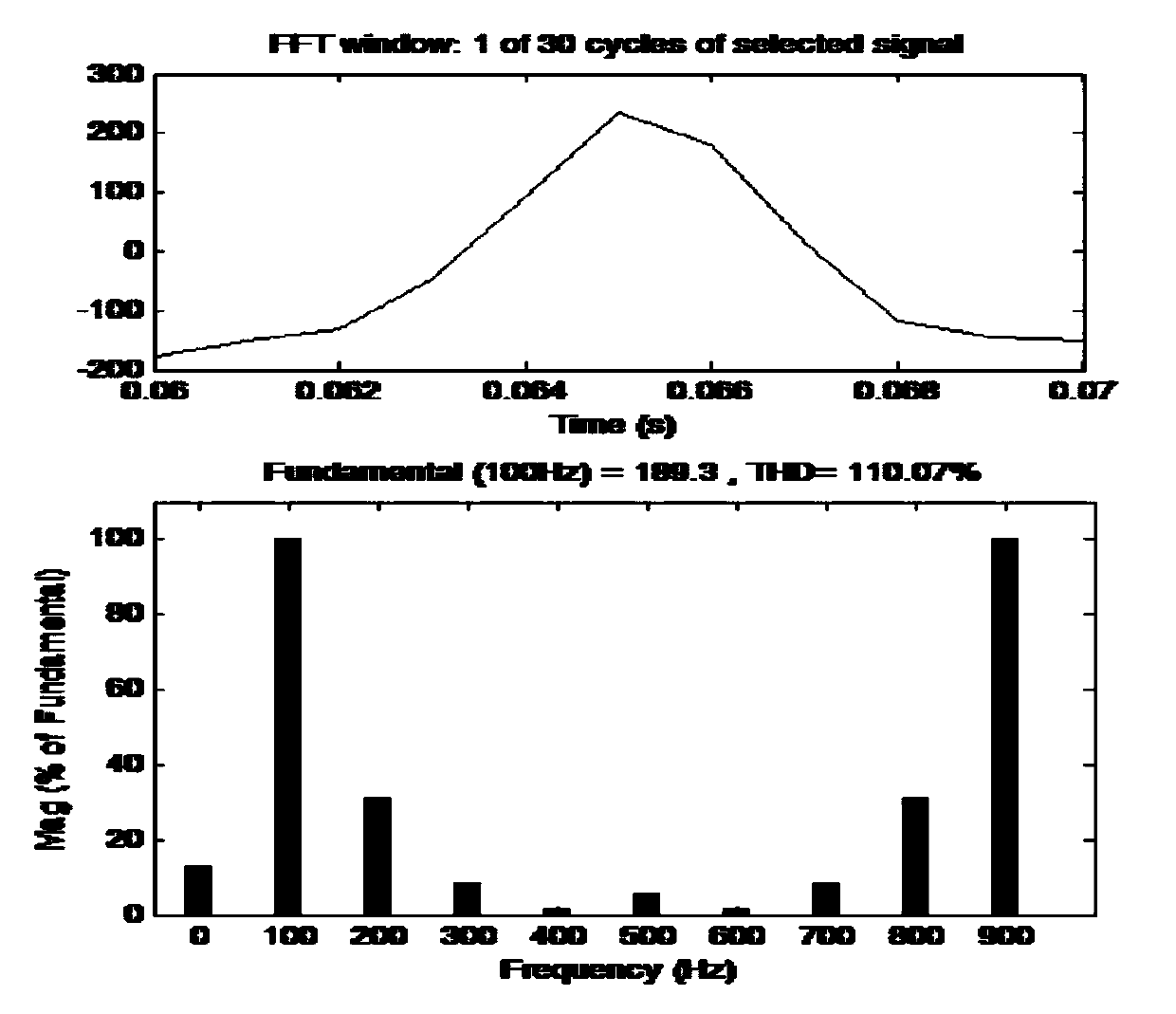

[0034] After the stator winding of the permanent magnet synchronous motor is supplied with three-phase AC sinusoidal power, a rotating magnetic field is generated on the stator winding coil, and the permanent magnet on the rotor generates a fixed magnetic field. The rotor magnetic field and the stator magnetic field interact through the air-gap flux to generate electromagnetic interaction between the rotor and stator surfaces. When the stator or rotor fails or the output current of the drive circuit changes, the normal air-gap flux waveform will be changed, thereby affecting the frequency of the three-phase alternating current on the stator. If the rotor has a broken bar fault, the magnetic field on the rotor will change, causing the air gap magnetic field between the rotor and the stator t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com