Architectural float glass ceramics crystallization annealing kiln and glass crystallization method

A glass-ceramic and annealing kiln technology, which is applied in the field of crystallization and annealing of flat glass-ceramics, can solve the problems of no application examples of float plate glass-ceramics, achieve the effect of neat and smooth cuts, satisfy crystallization annealing, and reduce intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

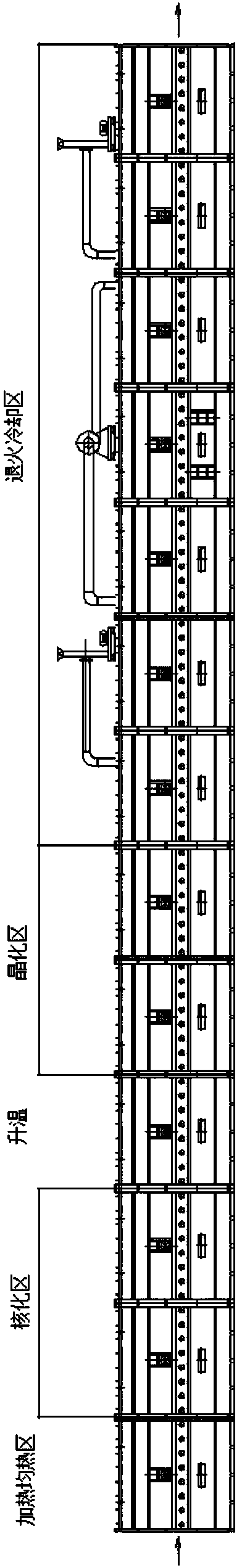

[0029] The annealing kiln for crystallization of glass-ceramics formed by the float method has a corresponding working capacity of 100 tons per day. The overall structure of the equipment is as follows figure 1 :

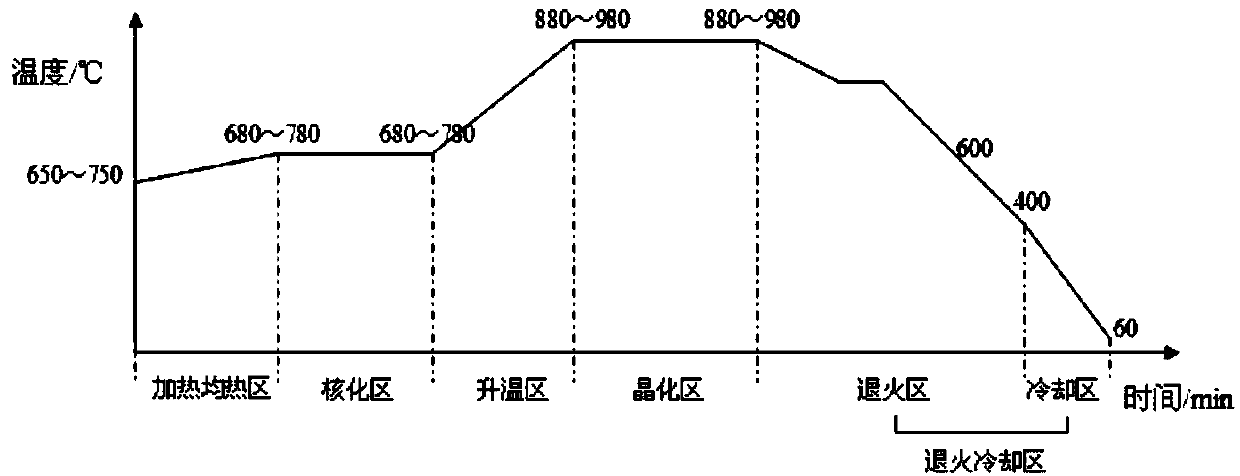

[0030] (1) The total length of the equipment is 342 meters. It is divided into nucleation zone, crystallization zone and annealing cooling zone from front to back. The nucleation area is 54 meters, the crystallization area is 54 meters, the annealing cooling area is 138 meters, and the remaining 96 meters are the heating area (including the heating area before the nucleation area and the area between the nucleation area and the crystallization area. The maximum temperature in the crystallization zone can reach 1100℃;

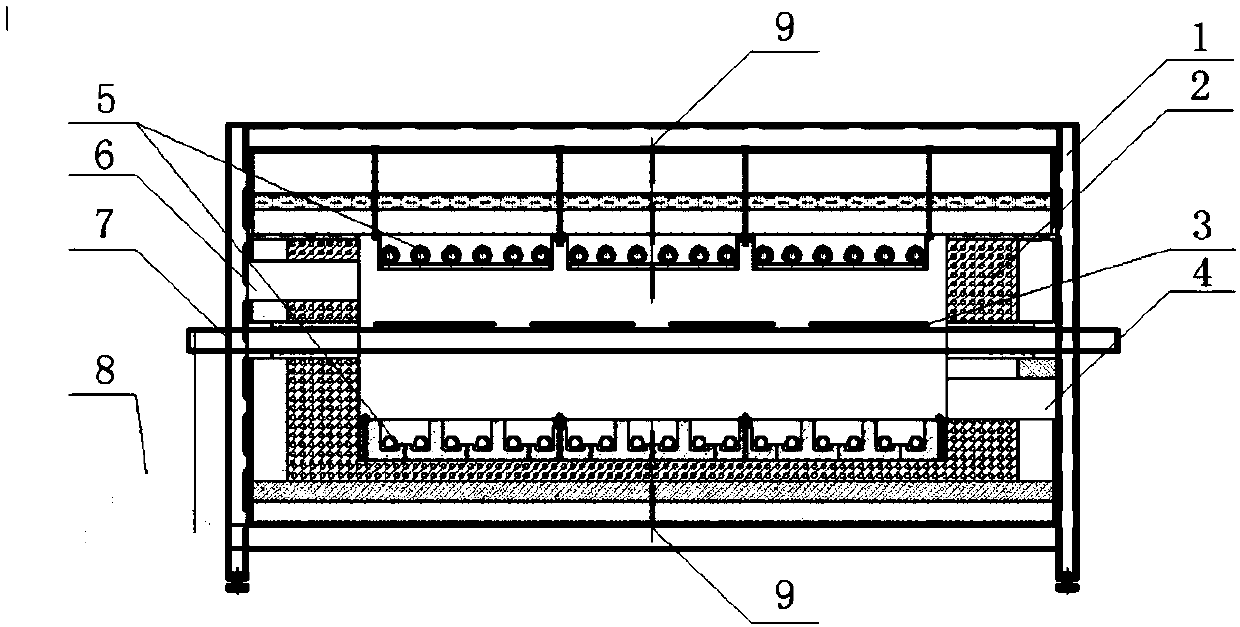

[0031] (2) The width of the original glass plate is 2 meters, and the plate thickness is 8 mm. According to the plate width, the inner width of the kiln is set to 2.4 meters. The glass is driven forward by the rollers at a uniform speed in the kiln. ...

Embodiment 2

[0034] Crystallization annealing kiln for glass-ceramics after float forming, the corresponding working capacity is 100 tons / day,

[0035](1) The total length of the equipment is 342 meters. It is divided into nucleation zone, crystallization zone and annealing cooling zone from front to back. Chemicalization and annealing work, in which the nucleation area is 54 meters, the crystallization area is 54 meters, the annealing cooling area is 138 meters, and the design maximum temperature of the crystallization area can reach 1100 ℃;

[0036] (2) The width of the original glass plate is 2.4 meters, and the plate thickness is 8mm. According to the plate width, the inner width of the kiln is set to 3 meters. The glass is driven forward by the rollers at a constant speed in the kiln. After the kiln, the nucleation treatment is carried out first, and the nucleation process is completed when passing through the nucleation zone; then the kiln slowly heats up to the crystallization tempe...

Embodiment 3

[0039] Crystallization annealing kiln for glass-ceramics after float forming, the corresponding working capacity is 100 tons / day,

[0040] (1) The total length of the equipment is 342 meters. It is divided into nucleation zone, crystallization zone and annealing cooling zone from front to back. Chemicalization and annealing work, of which the nucleation zone is 30 meters, the crystallization zone is 60 meters, the annealing cooling zone is 135 meters, and the remaining 117 meters are heating soaking zone and heating zone, and the crystallization zone is designed to have a maximum temperature of 1100°C;

[0041] (2) The width of the original glass plate is 2.4 meters, and the plate thickness is 8mm. According to the plate width, the inner width of the kiln is set to 3 meters. The glass is driven forward by the rollers at a uniform speed in the kiln. After the kiln, the nucleation treatment is carried out first, and the nucleation process is completed when passing through the nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com