Variable-flue-cross-section tubular air preheater

An air preheater and cross-section technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the phenomenon of aggravating the low temperature corrosion of heat exchange tube flue gas, low heat exchange tube wall temperature, etc. Insufficient height of the boiler, etc., to reduce the phenomenon of fouling and fouling, maintain the flow rate, and reduce fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

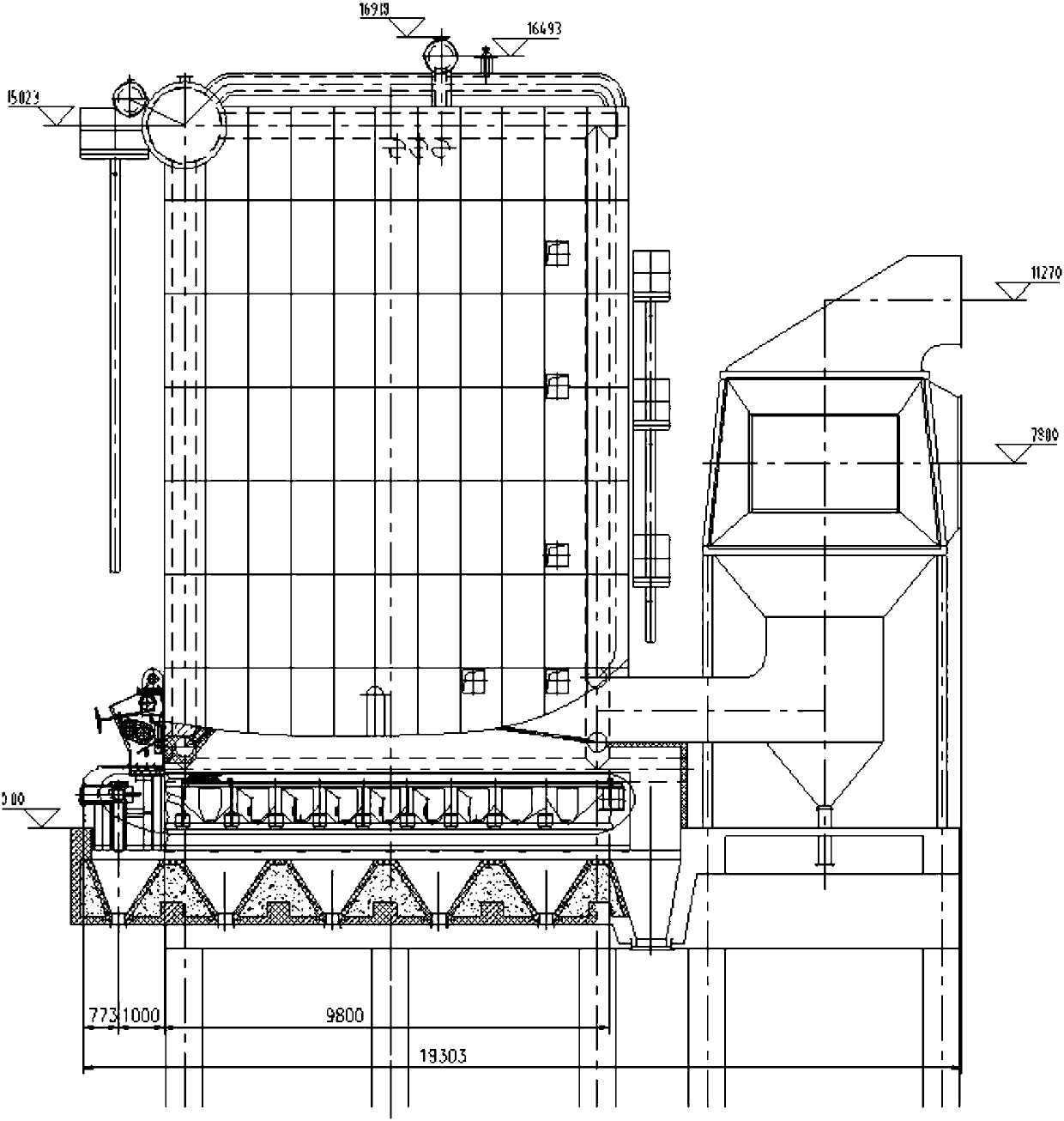

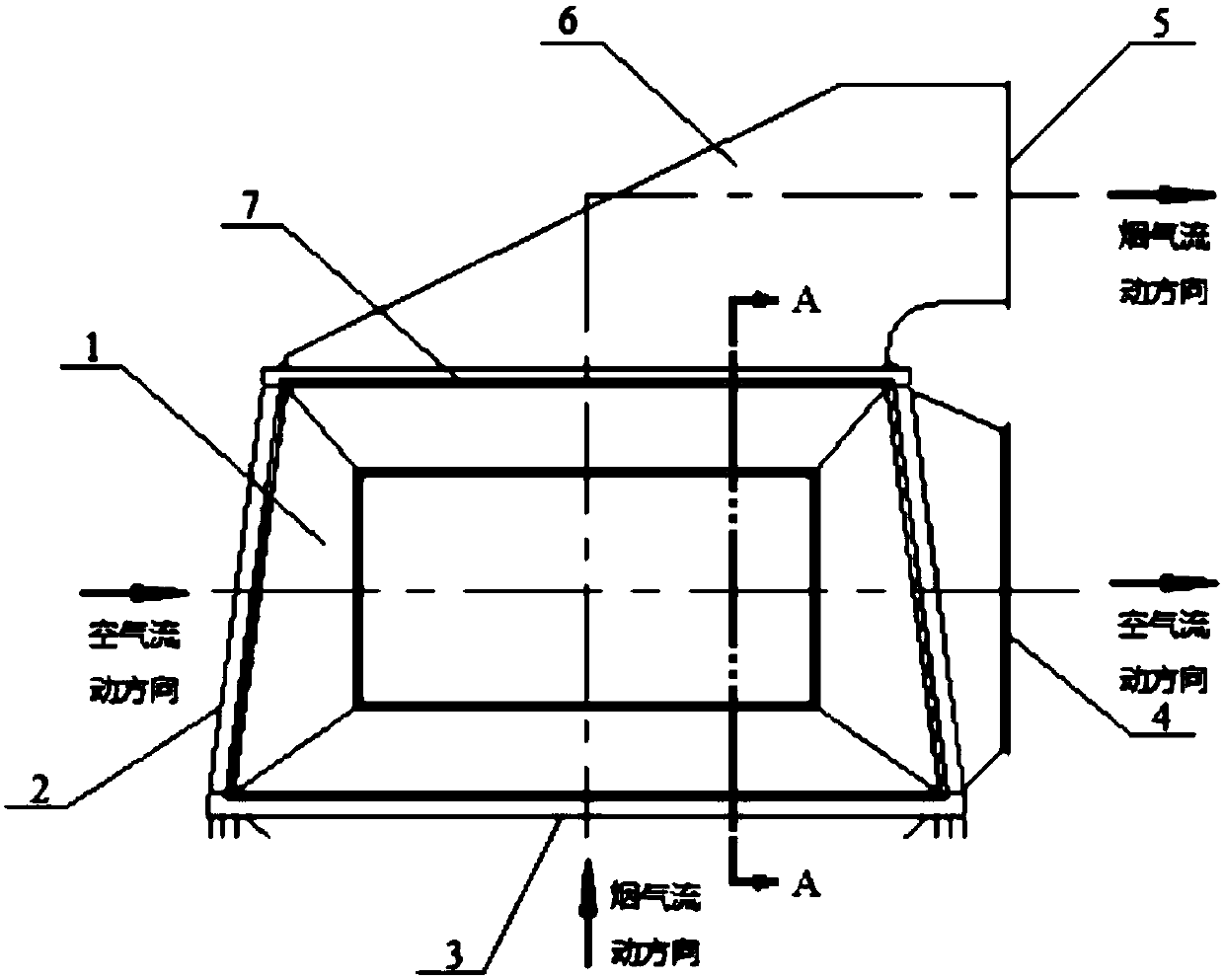

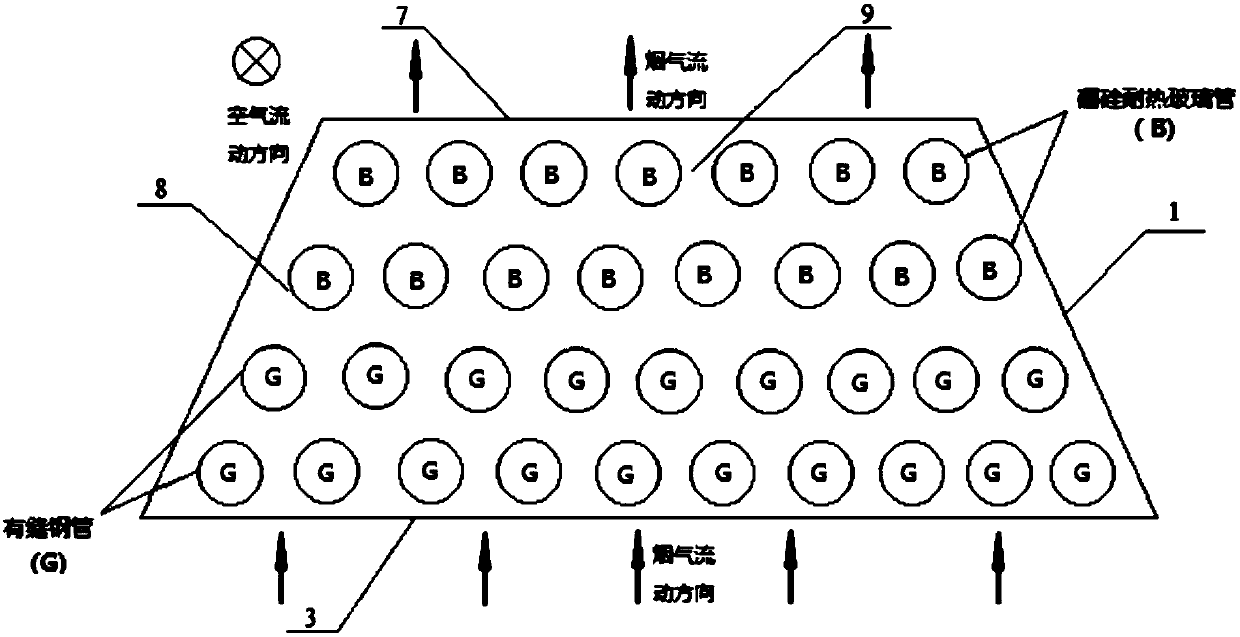

[0020] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 2 As shown, when the present invention is in use, the flue gas flows in from the flue gas inlet 3 below the air preheater shell 1, and the air flows in the heat exchange tubes 8 arranged horizontally, and the flue gas flows along the gap formed between the heat exchange tubes 8. The flue gas flow channel 9 goes up and scours the outer surface of the wall of the heat exchange tube 8 , and continuously transfers heat to the air in the heat exchange tube 8 . Specifically, the cold air to be heated flows into the air preheater shell 1 from the air inlet 2 on the left along the heat exchange tube 8, and the high-temperature flue gas flows in from the flue gas inlet 3 at the bottom of the air preheater shell 1. Going up along the flue gas flow channel 9, during this process, the outer wall of the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com