Fault diagnosis method for catalyzing and cracking main fractionator based on double-layer method

A fault diagnosis and catalytic cracking technology, applied in design optimization/simulation, instruments, complex mathematical operations, etc., can solve problems such as lowering diagnostic performance, not including transfer phenomenon equation fractionation tower, etc., to improve accuracy and operation speed, suitable for real-time Effects of fault diagnosis and economic loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

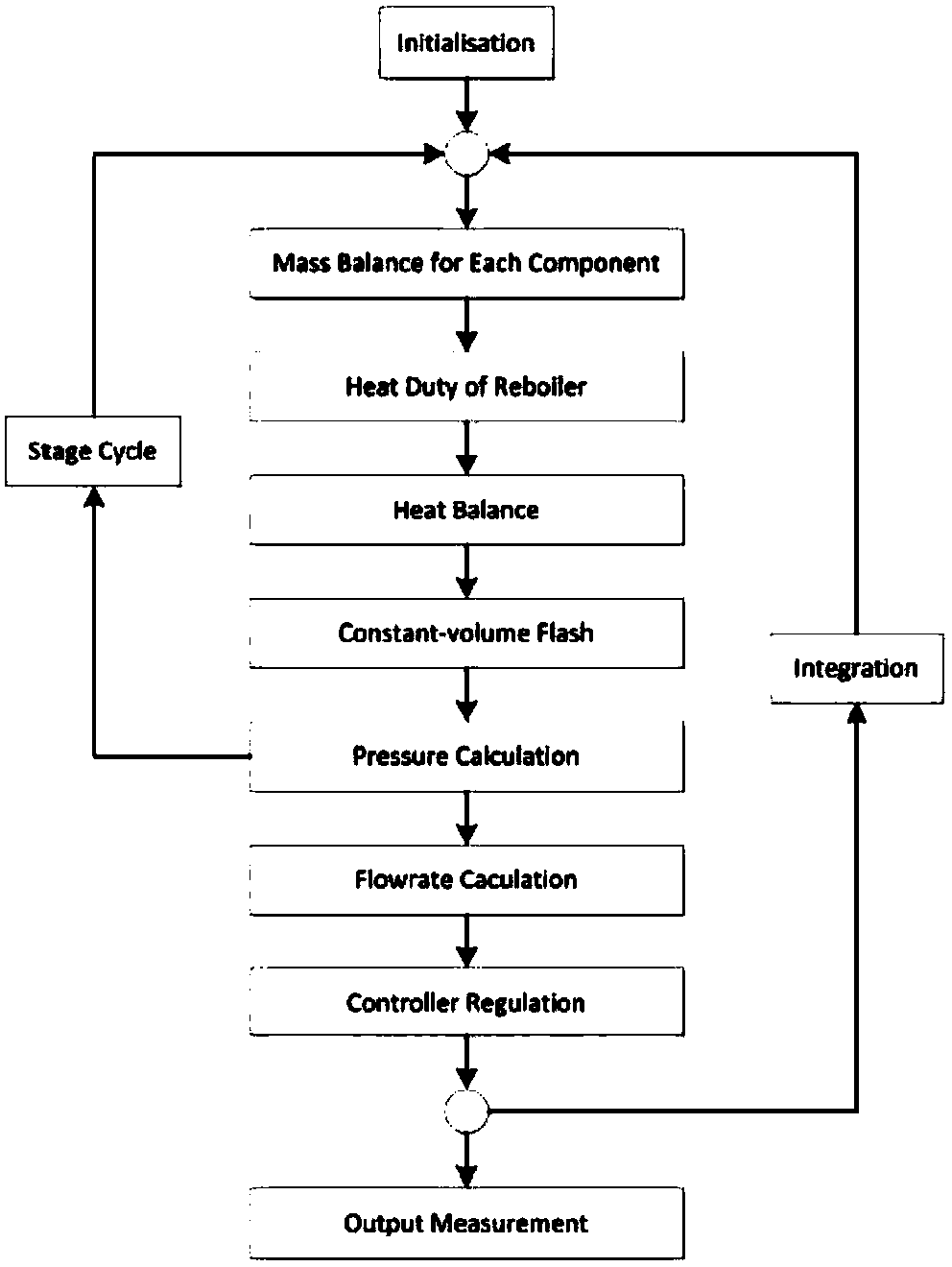

[0021] A method for detecting and diagnosing faults of catalytic cracking main fractionation towers based on a double-layer method, including the establishment of a double-layer fault diagnosis model, the specific steps of which are as follows:

[0022] (1) Based on the dynamic mechanism of the distillation process, the nonlinear fractionation column model is built by using the dynamic simulation and parameter correction process;

[0023] (2) Use the first-order Taylor expansion to linearize various equations of the nonlinear model to obtain a linear model;

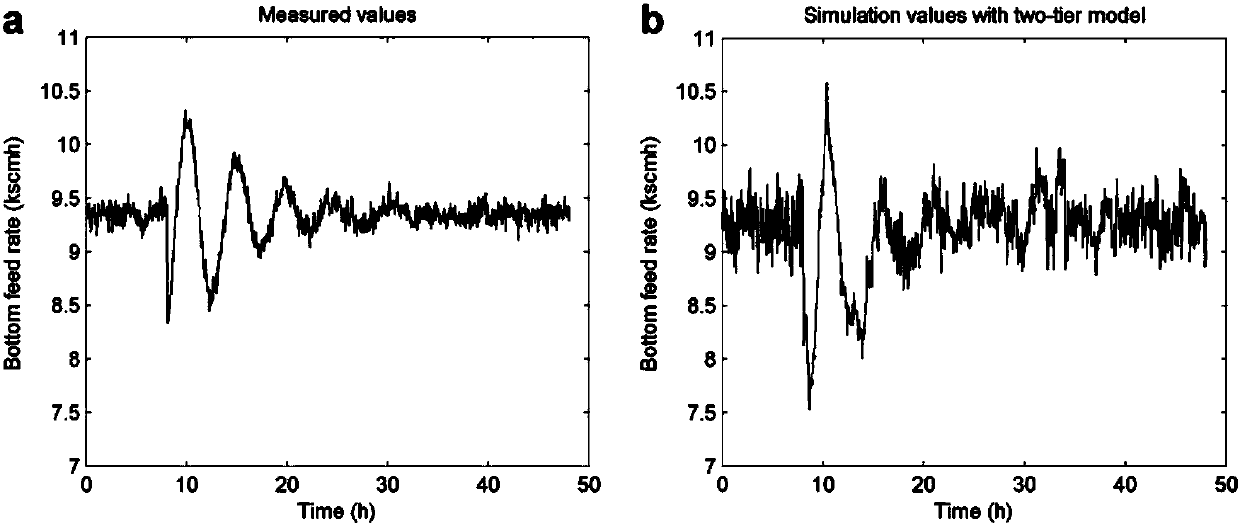

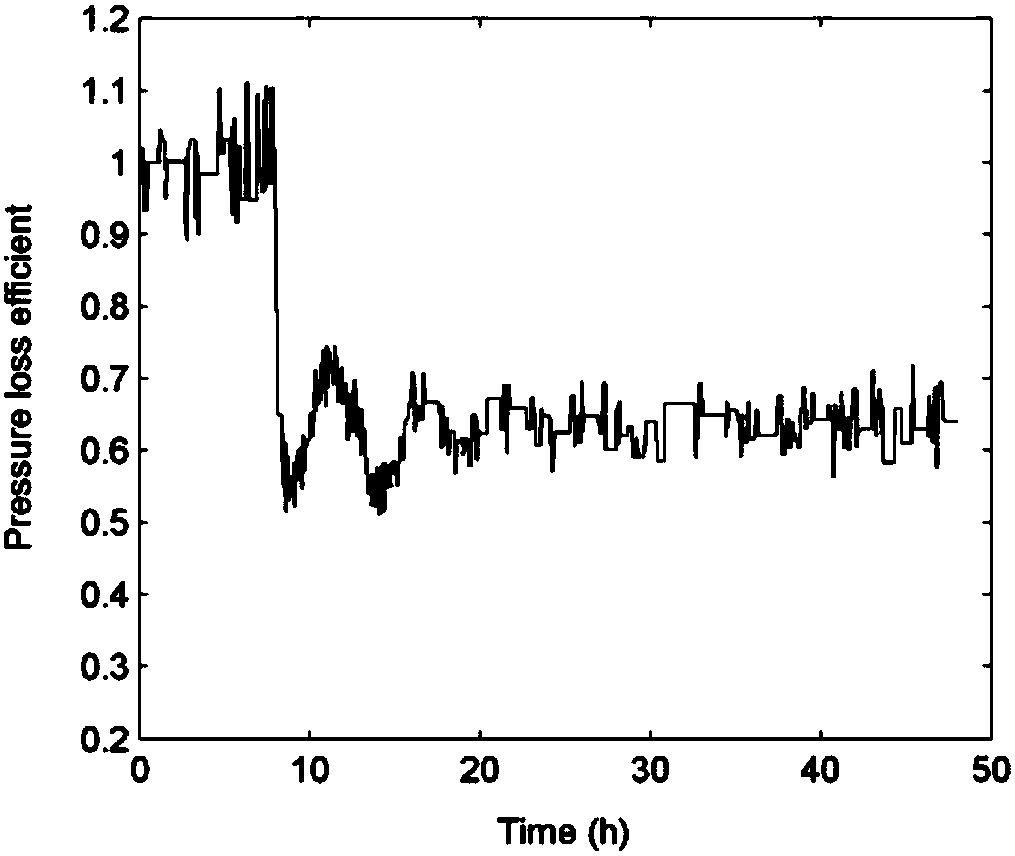

[0024] (3) Compare the dynamic simulation prediction data of the corresponding measured variables in the mechanism model with the historical data, and determine whether the device has failed by judging the statistic Q. If Q exceeds the threshold, the simplified linear model is used to obtain the fault parameters, and then the strict nonlinear model is used to correct the simulation results of the linear model, and the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com