A solid engine grain cleaning device

A solid engine and cleaning device technology, applied in the direction of driving devices, solid waste removal, auxiliary devices, etc., can solve the problems of high cost and insufficient recovery of waste medicine, so as to prevent the burning of the powder column, reduce the amount of chips, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

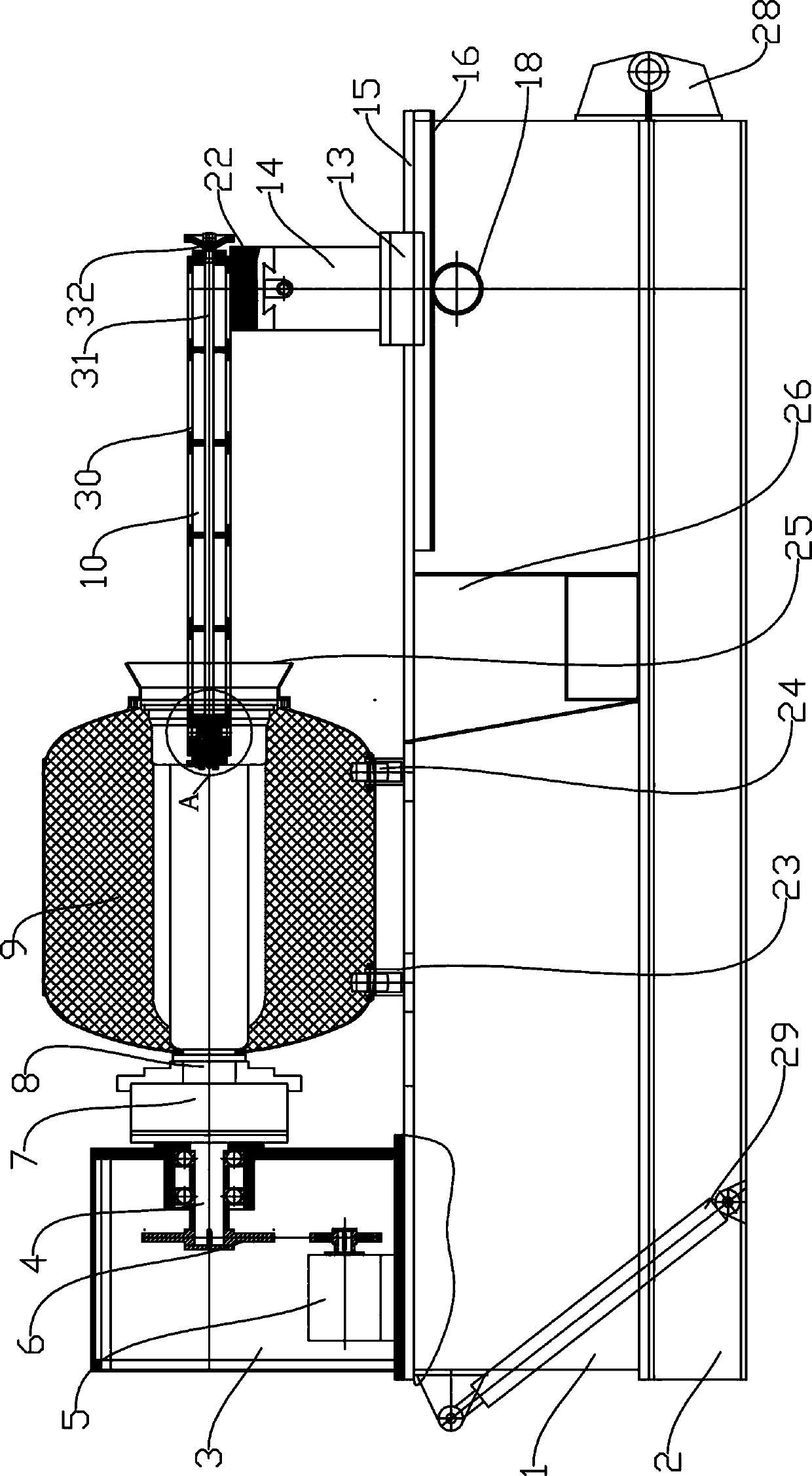

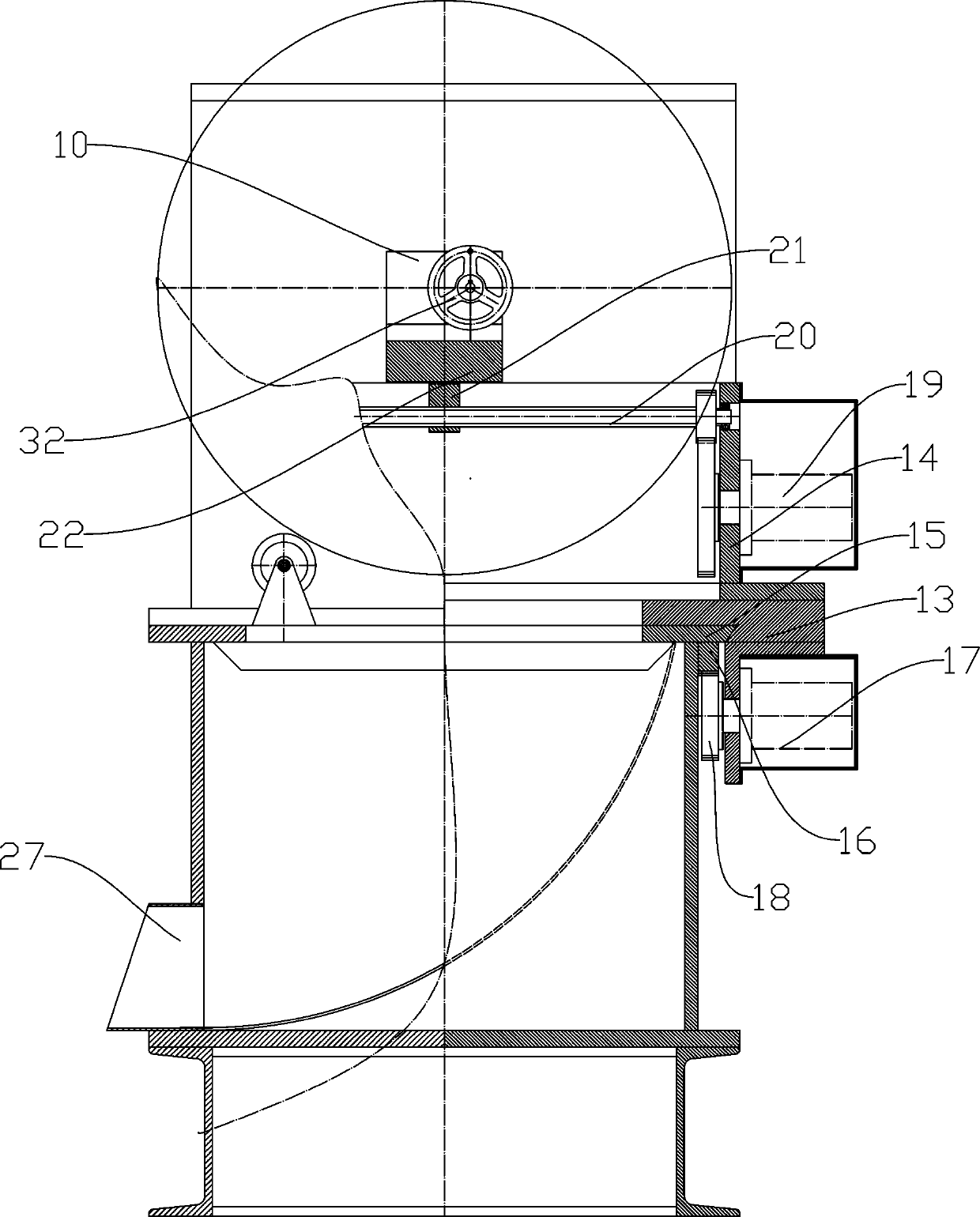

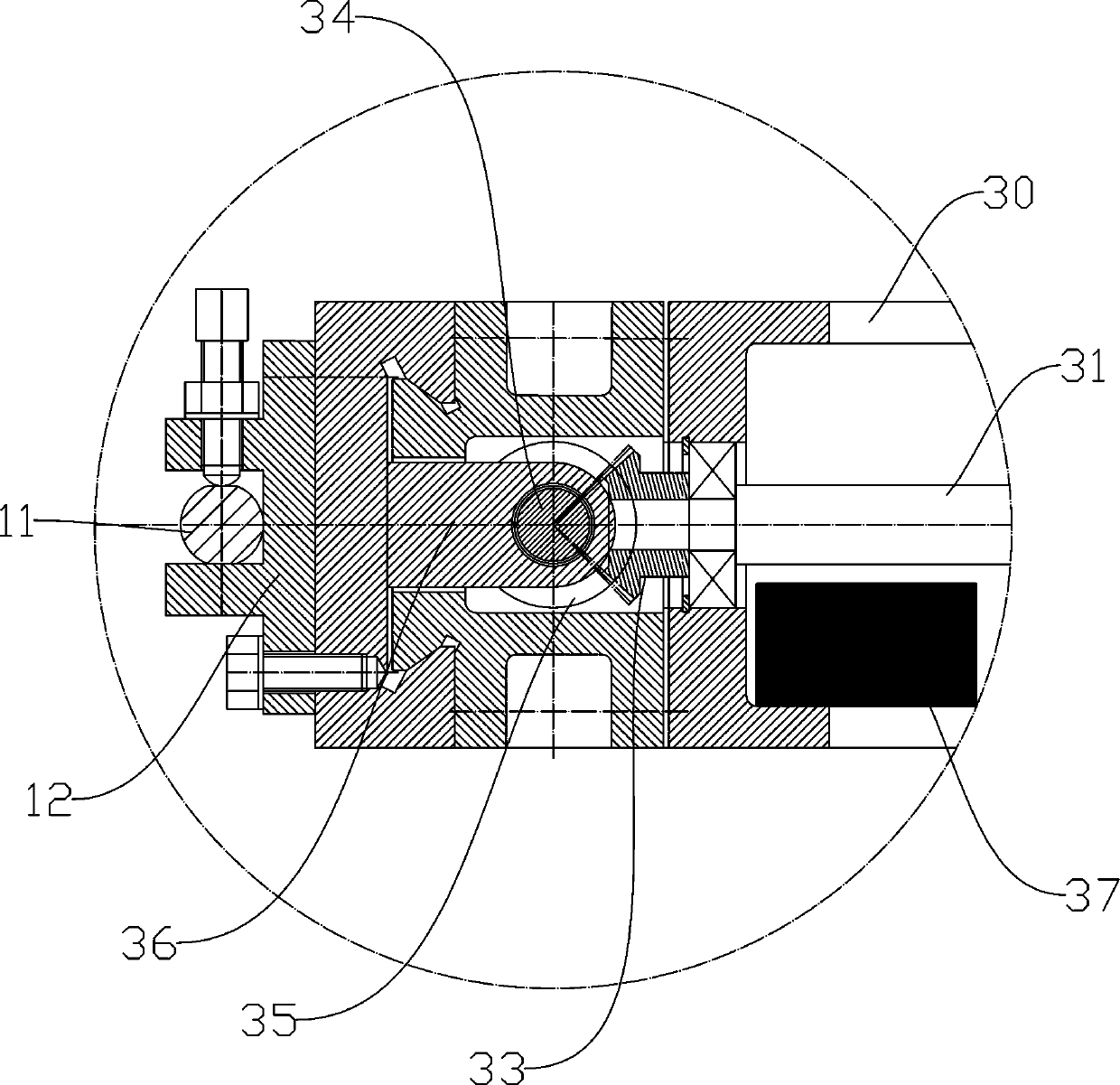

[0026] Such as Figure 1~2 Among them, a solid motor charge cleaning device, including a bed 1 and a pad frame 2 arranged under the bed 1, a bedside box 3 is arranged on the bedside 1, and a drive output shaft 4 is arranged in the bedside box 3 The rotating speed regulating motor 5 and the belt wheel system 6 matched with the speed regulating motor 5, the output shaft 4 is connected with the three-jaw chuck 7, and the three-jaw chuck 7 clamps one end of the transition tooling 8, and the other end of the transition tooling 8 One end is stuck on the charge port of the solid motor 9, and the cantilever cutter bar 10 is installed on the bed 1 through the feed structure. The feed structure includes a first pallet 13 and a second pallet 14 connected to the first pallet 13, The first pallet 13 can be longitudinally slidably installed on the bed guide rail 15, the rack 16 is installed on the bed 1, the first servo motor 17 is arranged on the first pallet 13, and the rotating shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com