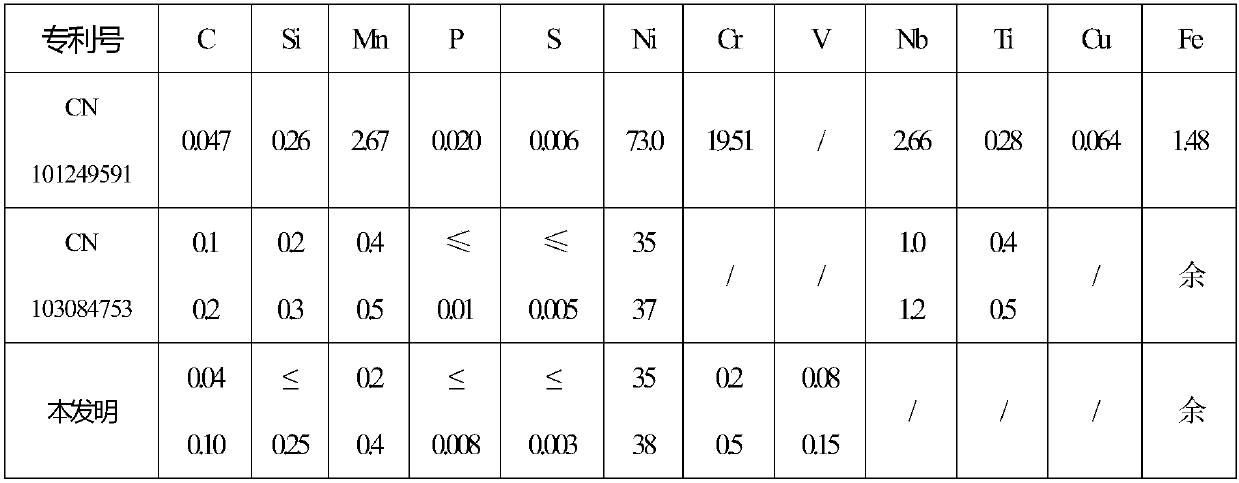

Fe-Ni invar alloy welding wire and manufacturing method thereof

A technology of Invar alloy and manufacturing method, applied in the field of alloy welding wire and its production, can solve the problems of high content, low expansion and high cost, and achieve the effects of low expansion performance, low manufacturing cost, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

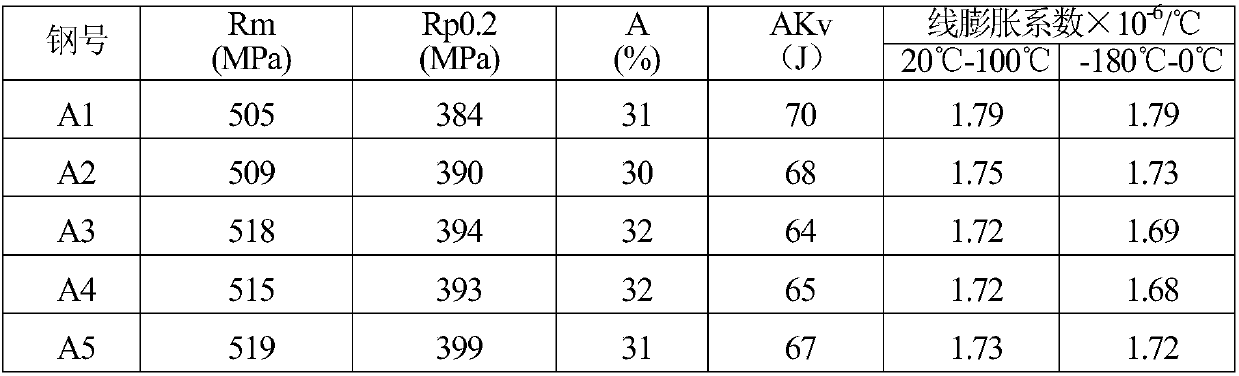

Examples

Embodiment 1

[0050] According to the above-mentioned smelting method, the molten steel with chemical composition A1 was prepared. The vacuum treatment time was 15 minutes below 66.7 Pa. After the vacuum treatment, the bottom blowing Ar stirring time was 20 minutes. The pouring temperature was 1480 ° C, pouring 2.3 tons of steel ingots, and the heating temperature of the steel ingots was 1180 ° C. , heat preservation for 3 hours, starting rolling temperature 1090°C, final rolling temperature 870°C, rolled finished Φ5.5mm wire rod, solid solution at 950°C, water cooling after heat preservation for 2h, and cold drawing into Φ1.2mm wire rod according to the conventional process.

Embodiment 2

[0052] According to the above-mentioned smelting method, the molten steel with chemical composition A2 was prepared. The vacuum treatment time was 18 minutes below 66.7 Pa. After the vacuum treatment, the bottom blowing Ar stirring time was 20 minutes. The pouring temperature was 1485 ° C, pouring 2.3 tons of steel ingots, and the heating temperature of the steel ingots was 1150 ° C. , heat preservation for 3 hours, starting rolling temperature 1060°C, final rolling temperature 820°C, rolled finished Φ5.5mm wire rod, solid solution at 980°C, water cooling after heat preservation for 2 hours, and cold drawing into Φ1.2mm wire rod according to the conventional process.

Embodiment 3

[0054] According to the above-mentioned smelting method, the molten steel with the chemical composition A3 was prepared, and the vacuum treatment time was 15 minutes below 66.7 Pa. After the vacuum treatment, the bottom blowing Ar stirring time was 22 minutes. The pouring temperature was 1190 ° C, pouring 2.3 tons of steel ingots, and the heating temperature of the steel ingots was 1160 ° C. , heat preservation for 3 hours, starting rolling temperature 1090°C, final rolling temperature 850°C, rolled finished Φ5.5mm wire rod, solid solution at 1100°C, water cooling after heat preservation for 2 hours, and cold drawing into Φ1.2mm wire rod according to the conventional process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com