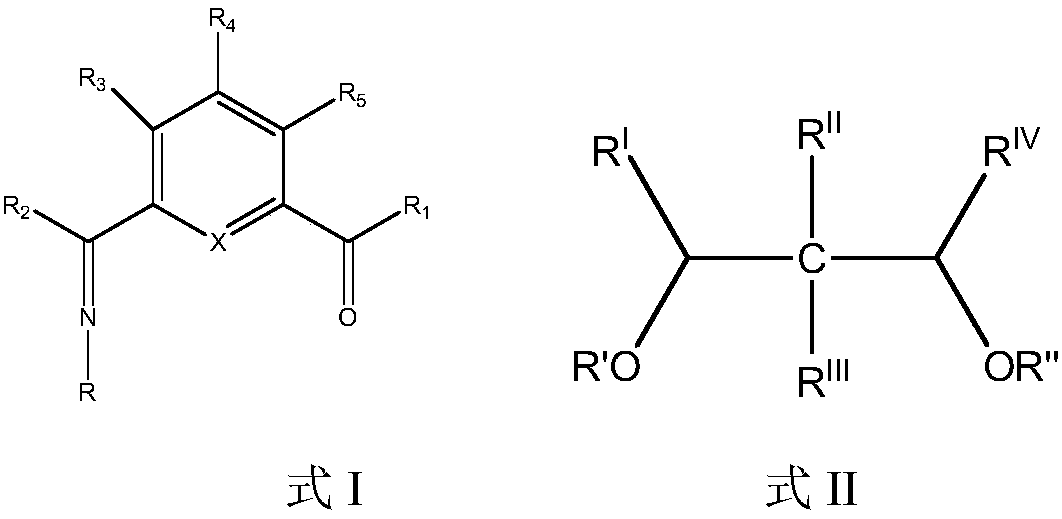

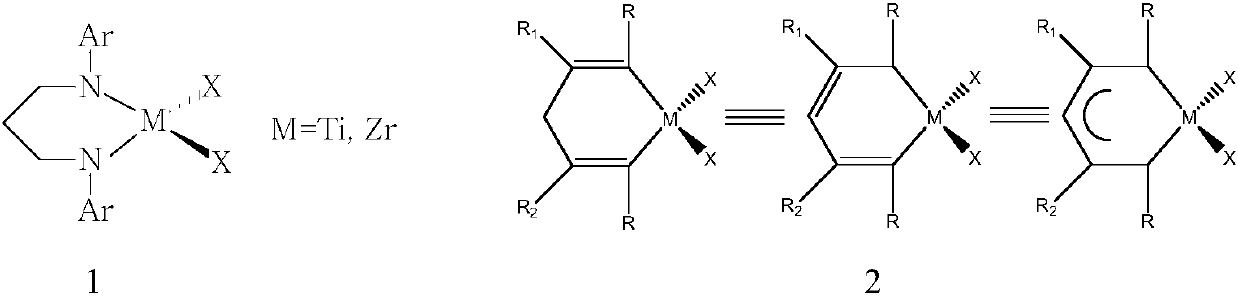

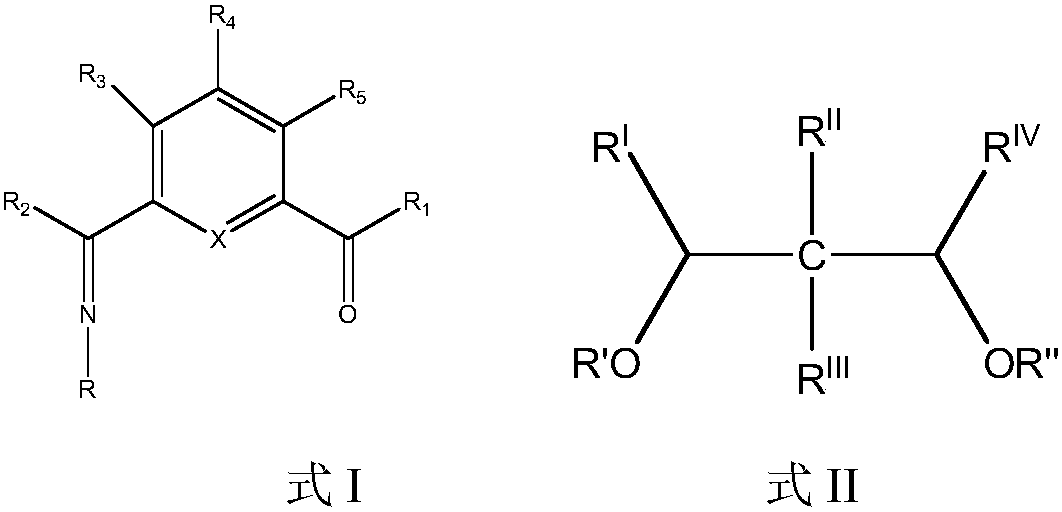

Catalyst component and catalyst used for olefin polymerization, and application thereof

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization and can solve problems such as ligand compounds that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Synthesis of 6-(phenylimino)ethyl-2-acetylpyridine: In a 250 ml three-necked flask, add 3.26 g of 2,6-diacetylpyridine, 100 ml of isopropanol and 0.2 ml of ice Acetic acid, stir well at room temperature. At room temperature, 1.96 g of aniline dissolved in 20 ml of isopropanol solution was slowly added dropwise. After the addition was completed, the reaction was stirred for 2 hours, and then the temperature was raised to reflux for 12 hours. The reaction solution was concentrated under reduced pressure and separated by column chromatography to obtain 2.83 g of 6-(phenylimino)ethyl-2-acetylpyridine (62% yield). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):8.46~8.42(2H,m,ArH),7.96~7.93(2H,m,ArH),7.32~7.28(2H,m,ArH),7.10~7.06(2H,m,ArH),2.35~2.32( 3H,s,CH 3 ),1.15~1.12(3H,s,CH 3 ); Mass Spectrum, FD-MS: 238.

Embodiment 2

[0050] Synthesis of 6-(4-chlorophenylimino) ethyl-2-acetylpyridine: In a 250 ml three-necked flask, add 1.63 g of 2,6-diacetylpyridine, 80 ml of isopropanol and 0.2 ml of glacial acetic acid, stirred well at room temperature. Slowly add 1.27 g of p-chloroaniline dissolved in 20 ml of isopropanol solution dropwise at room temperature, stir and react for 2 hours after the addition, then raise the temperature and reflux for 18 hours. The reaction solution was concentrated under reduced pressure and separated by column chromatography to obtain 1.63 g of 6-(4-chlorophenylimino)ethyl-2-acetylpyridine (69% yield). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):8.44~8.40(2H,m,ArH),816~8.14(1H,m,ArH),7.46~7.41(2H,m,ArH),7.12~7.08(2H,m,ArH),2.38~2.34( 3H,s,CH 3 ),1.12~1.09(3H,s,CH 3 ); Mass Spectrum, FD-MS: 272.

Embodiment 3

[0052] Synthesis of 6-(2,6-diisopropylphenylimino)ethyl-2-acetylpyridine: In a 250 ml three-necked flask, add 1.63 g of 2,6-diacetylpyridine, 80 mL of isopropanol and 0.1 mL of glacial acetic acid, stirred well at room temperature. 1.78 g of 2,6-diisopropylaniline dissolved in 20 ml of isopropanol solution was slowly added dropwise at room temperature. After the addition was completed, the mixture was stirred for 2 hours and then heated to reflux for 12 hours. The reaction solution was concentrated under reduced pressure and separated by column chromatography to obtain 2.32 g of 6-(2,6-diisopropylbenimino)ethyl-2-acetylpyridine (yield 72%). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):8.45~8.41(2H,m,ArH),7.96~7.92(2H,m,ArH),7.36~7.34(2H,m,ArH),3.22~3.18(2H,m,CH),2.27~2.24( 3H,s,CH 3 ),1.28~1.24(6H,m,CH 3 ),1.14~1.10(6H,m,CH 3 ),1.10~1.07(3H,s,CH 3 ); Mass Spectrum, FD-MS: 322.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com