Catalyst component for olefin polymerization and catalyst

A technology of olefin polymerization and catalyst, which is applied in the production of bulk chemicals, etc., and can solve the problems of difficult synthesis process of internal electron donor compounds, poor sensitivity to hydrogen adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Preparation of spherical catalyst solid components

[0062] Prepare spherical magnesium chloride alcoholate MgX with reference to the embodiment 1 method in Chinese patent CN1091748A 2 ·(ROH) m , where X=Cl, R=C 2 h 5 , m=2.4.

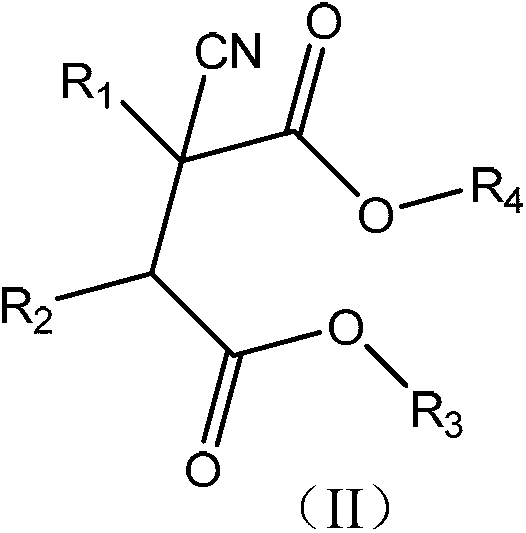

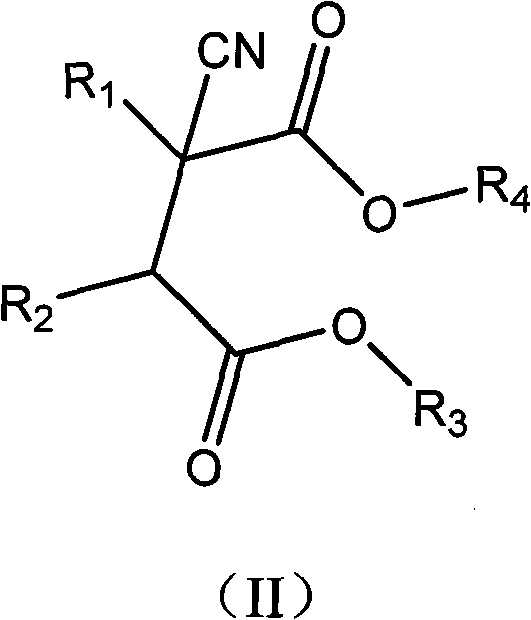

[0063] In a 300ml double-layer glass reaction bottle, add 100ml of titanium tetrachloride, cool to -20°C, add 8 grams of the above-mentioned spherical magnesium chloride alcoholate, heat up to 100°C, and add according to the Chinese invention patent application number during the heating process. 2.5mmol of 2,3-diisopropyl-2-cyanodiethyl succinate prepared by the method described in the patent application description of 200910077779.6, 2.5mmol of diisobutyl phthalate, filter off the liquid, and use four Titanium chloride was washed twice, washed four times with hexane, and vacuum-dried to obtain a spherical catalyst solid component. Infrared spectrogram data of catalyst solid components:

[0064] IR (cm -1 ): 2291, 1701, 1459, 1378, 12...

Embodiment 2

[0069] (1) preparation of spherical catalyst solid component, with embodiment 1.

[0070] (2) Propylene polymerization

[0071] In a 5L autoclave, 5ml of a hexane solution of triethylaluminum (the concentration of triethylaluminum is 0.5mmol / ml), 1.25ml of cyclohexylmethyldimethoxysilane (CHMMS ) in hexane solution (the concentration of CHMMS is 0.1 mmol / ml), 10 ml of anhydrous hexane and 10 mg of the solid catalyst component obtained above. Close the autoclave, introduce 6 L of hydrogen gas (standard volume) and 2.3 L of liquid propylene, raise the temperature to 70° C., and polymerize for 1 hour. The test results are shown in Table 1.

Embodiment 3

[0073] (1) The preparation of the solid component of the spherical catalyst is the same as in Example 1, except that diisobutyl phthalate is replaced by 9,9-di(methoxymethyl)fluorene (2.5 mmol).

[0074] Infrared spectrogram data of catalyst solid components:

[0075] IR (cm -1 ): 2286, 1697, 1637, 1460, 1377, 1294, 1009, etc.

[0076] The wavelength dispersive X-ray fluorescence spectrometry (WDXRF) analysis results of the solid components of the catalyst: Mg 21.8%, Cl 74.8%, Ti 3.0%, and the balance is other elements.

[0077] (2) The propylene polymerization method is the same as that of Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com