Hardener for epoxy resin and preparing method thereof

A technology of curing agent for epoxy resin, which is applied in the field of curing agent for epoxy resin and its preparation, and can solve the problems of high hygroscopicity of cured products, reduced mechanical properties, and inability to increase adhesive force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

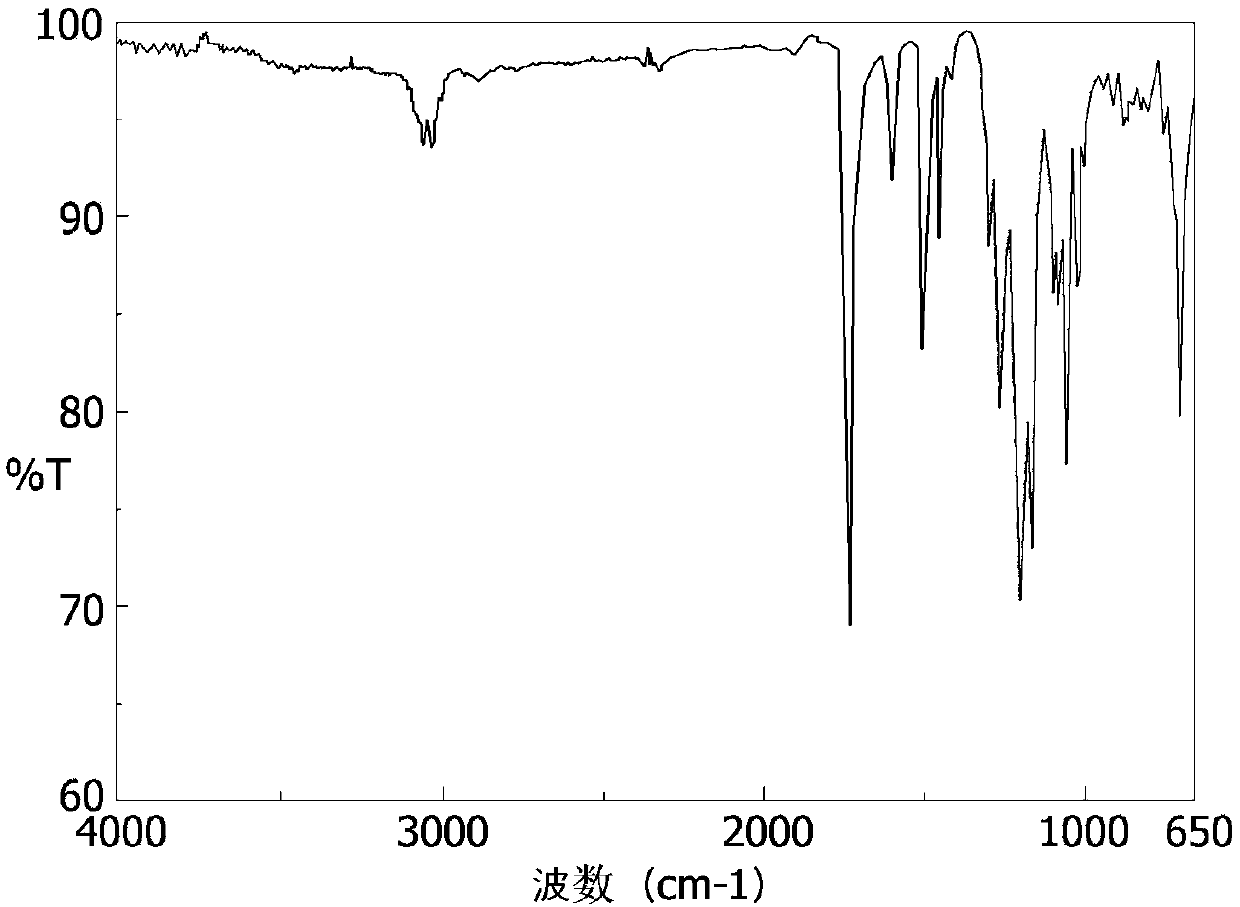

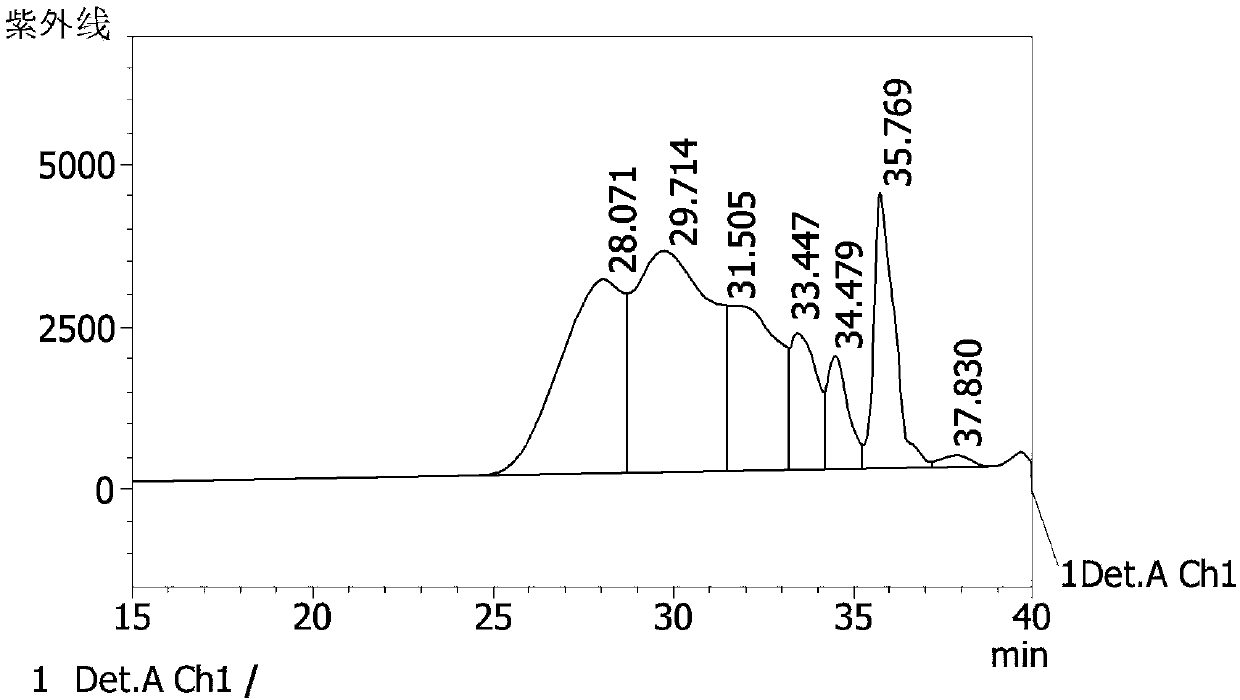

Image

Examples

preparation example Construction

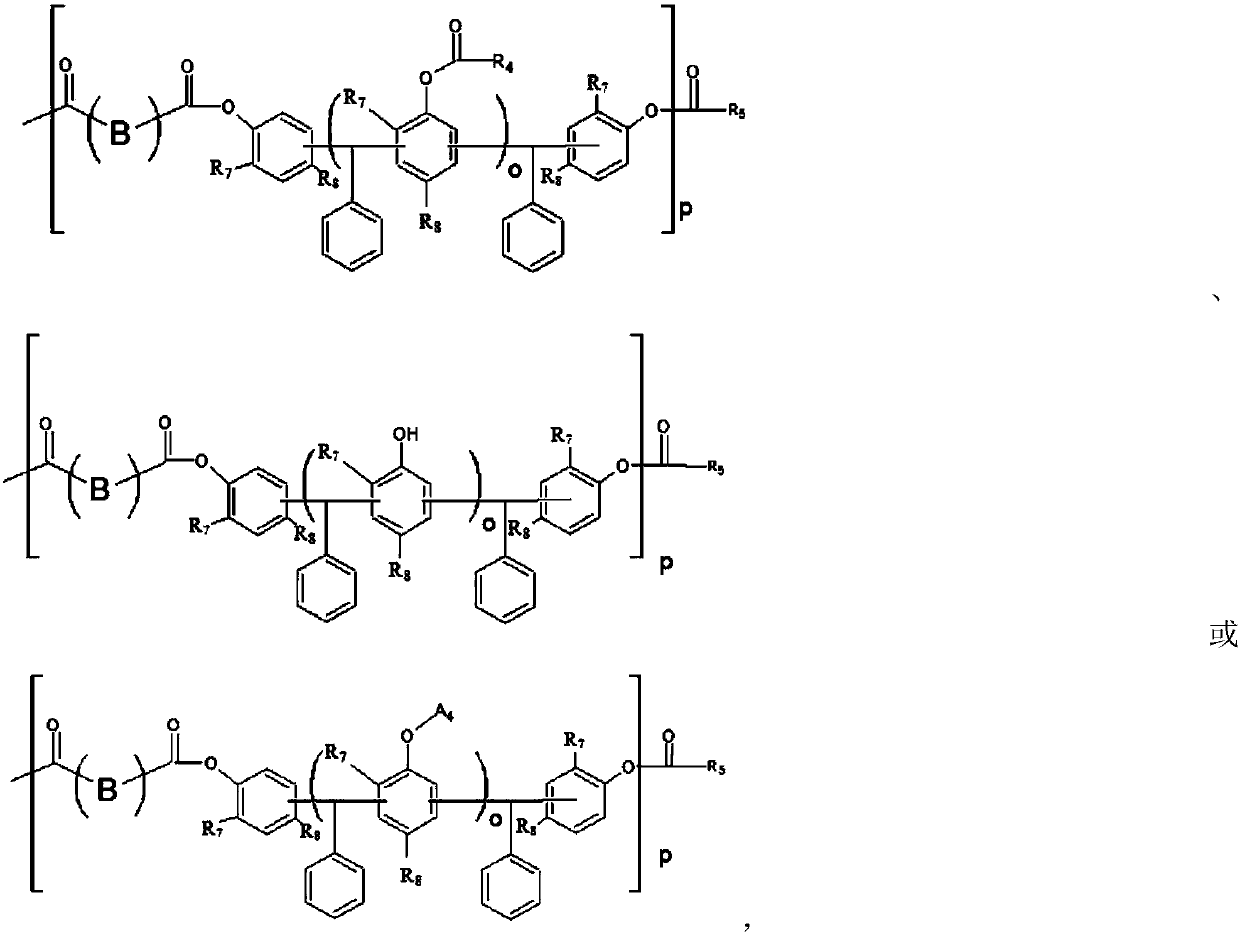

[0098] Next, the present invention provides a method for preparing a curing agent for epoxy resin. The method for preparing a curing agent for epoxy resin includes: step 1, introducing the following chemical formula 2. A monomer represented by Chemical Formula 3 and Chemical Formula 4; and a step 2 of preparing a copolymer represented by the following Chemical Formula 1 by reacting the monomer introduced in the above-mentioned Step 1.

[0099] Chemical formula 2:

[0100] In the above chemical formula 2, a is a rational number from 0 to 8, if the above R 7 and R 8 Both are hydrogen atoms or R 7 and R 8 One of them is a hydrogen atom, and the other is a methyl group.

[0101] Chemical formula 3:

[0102] In the above chemical formula 3, B is x 1 is a halogen atom.

[0103] Chemical formula 4:

[0104] In the above chemical formula 4, X 2 is a halogen atom, R 6 It is a substituted or unsubstituted aryl group having 6 to 24 carbon atoms or an alkyl group having ...

Embodiment 1

[0129] Embodiment 1. The preparation of curing agent for epoxy resin

[0130] Step 1: Introduce 1450 g of toluene as an organic solvent, 306 g of a monomer (0.45 mol) represented by the following chemical formula 2-1, and 81.2 g of a monomer represented by the following chemical formula 2-1 into a reaction tank with a nitrogen input tube, a thermometer, and a circulating cooler attached to it. A monomer represented by 3-2 (0.4 mol), 168.68 g of a monomer represented by the following Chemical Formula 4-1 (1.2 mol).

[0131] Step 2: Under the condition of nitrogen input and temperature of 30°C, completely dissolve the monomers represented by the following chemical formula 2-1, chemical formula 3-2 and chemical formula 4-1 introduced in the above step 1, and 202.38g of triethyl After the amine (2 moles) was uniformly added dropwise for 2 hours, an aging process was performed for 2 hours. During the dropping and aging steps, the reaction temperature did not exceed 50°C.

[0132] ...

Embodiment 2

[0137] Embodiment 2. The preparation of curing agent for epoxy resin

[0138] Prepared in the same manner as in Example 1, 306g (0.45 mol), 97.45g (0.48 mol), and 146.19g (1.04 mol) of the compounds represented by the above chemical formula 2-1, chemical formula 3-2 and chemical formula 4-1 were dropped into respectively. Monomer, to obtain 440g of the weight average molecular weight (molecular weight) is the curing agent for epoxy resin of the following table 1 that is the brown solid of 7180.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com