Electric power circuit damper

A technology for power lines and anti-vibration hammers, applied in mechanical vibration damping devices and other directions, can solve the problems of inability to achieve anti-vibration effects and low self-resistance, and achieve the effects of suppressing breeze vibration, reducing resistance, and reducing power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

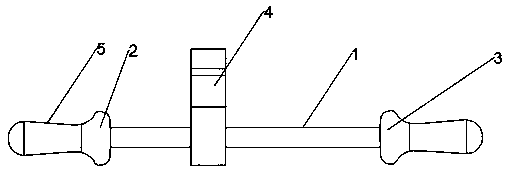

[0021] A power line anti-vibration hammer, such as figure 1 As shown, the two ends of the anti-vibration hammer strand 1 are fixed with a first hammer 2 and a second hammer 3, and the anti-vibration hammer strand 1 is integrally formed with the first hammer 2 and the second hammer 3, which can make the anti-vibration The connection between the stranded wire of the vibrating hammer and the hammer head is more reliable, and the hammer head will not fall off. The anti-vibration hammer strand 1 is connected with a clamp 4, and the clamp 4 is arranged between the first hammer head 2 and the second hammer head 3. The hammer heads on both sides of the anti-vibration hammer strand 1 have an asymmetric structure, and the clamp 4 The distances from the first hammer head 2 and the second hammer head 3 are different, the distance between the first hammer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com